In short, Polytetrafluoroethylene (PTFE) is an exceptional electrical insulator. It possesses a very high dielectric strength, capable of withstanding voltages up to 1500 volts without breaking down. This, combined with its high electrical resistance and low dielectric constant, makes it one of the most reliable and widely used insulating materials for demanding applications.

The true value of PTFE as an insulator isn't just one single property, but its unique combination of excellent electrical characteristics with extreme resistance to heat, chemicals, and moisture. This synergy ensures stable, long-lasting performance in environments where other materials would quickly fail.

The Core Electrical Properties of PTFE

To understand PTFE's capability, we must look at three primary electrical characteristics that define its performance as an insulator.

High Dielectric Strength

Dielectric strength measures a material's ability to withstand a strong electric field without failing and allowing current to pass through.

PTFE excels in this area, reliably preventing electrical breakdown under high voltage stress, making it ideal for insulating high-voltage wires, cables, and connectors.

High Electrical Resistivity

Resistivity indicates how strongly a material opposes the flow of electric current. PTFE has extremely high volume and surface resistivity.

This means it effectively stops current leakage, ensuring that electricity stays within its intended path and protecting sensitive electronic components.

Low Dielectric Constant

The dielectric constant is critical for high-frequency applications, such as in telecommunications and advanced electronics.

PTFE's very low dielectric constant ensures minimal energy loss and signal distortion as frequencies increase, preserving signal integrity in coaxial cables and circuit boards.

Why PTFE Excels in Demanding Environments

PTFE's elite status as an insulator is cemented by its ability to maintain its electrical properties under harsh operational conditions.

Unmatched Chemical Resistance

PTFE is virtually inert, remaining unaffected by nearly all industrial solvents, acids, and bases.

This chemical stability means the integrity of the insulation is not compromised by exposure to corrosive substances, ensuring long-term reliability.

Extreme Temperature Stability

PTFE performs consistently across an incredibly wide temperature range, from cryogenic lows (-268°C / -450°F) to high heat (260°C / 500°F).

Unlike many plastics that become brittle or melt, PTFE's electrical properties remain stable, making it suitable for aerospace, automotive, and industrial applications.

Resistance to Environmental Factors

PTFE has extremely low surface tension, which makes it both hydrophobic (water-repellent) and oleophobic (oil-repellent).

This prevents the formation of conductive films from moisture or grease on its surface, which could otherwise lead to tracking currents and insulation failure.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE's properties are exceptional, it's important to consider its practical limitations.

Mechanical Considerations

PTFE is a relatively soft material and can be susceptible to "cold flow" or creep, where it deforms under sustained pressure. This must be accounted for in designs where the insulator also serves a structural role.

It also has lower resistance to abrasion and cutting compared to harder plastics, so it may require external protection in physically abrasive environments.

Cost and Processing

PTFE is a high-performance polymer and is generally more expensive than common insulators like PVC or polyethylene.

Its unique properties also require specialized processing techniques, which can add to the final component cost.

Making the Right Choice for Your Application

Your final decision should be based on the most critical demands of your project.

- If your primary focus is high-frequency performance: PTFE's low dielectric constant is a key advantage that makes it a superior choice for preserving signal integrity.

- If your primary focus is reliability in harsh environments: PTFE's unmatched chemical inertness and wide temperature range provide unparalleled operational safety and longevity.

- If your primary focus is a simple, cost-sensitive application: You may want to evaluate other common insulators, as PTFE's high performance may be unnecessary for the application.

Ultimately, PTFE is the definitive choice when electrical insulation failure is not an option.

Summary Table:

| Property | Value / Description | Key Benefit |

|---|---|---|

| Dielectric Strength | Withstands up to 1500 V | Prevents electrical breakdown under high voltage |

| Volume Resistivity | Extremely High (>10^18 Ω·cm) | Stops current leakage effectively |

| Dielectric Constant | Very Low (~2.1) | Minimizes signal loss in high-frequency applications |

| Temperature Range | -268°C to +260°C | Stable performance from cryogenic to high heat |

| Chemical Resistance | Virtually Inert | Unaffected by almost all solvents, acids, and bases |

Need High-Performance PTFE Insulation Components?

When your application demands the ultimate in electrical insulation reliability—whether for the semiconductor, medical, laboratory, or industrial sector—KINTEK is your trusted partner. We specialize in the precision manufacturing of custom PTFE components like seals, liners, and labware.

We deliver value by:

- Ensuring Unmatched Reliability: Our components leverage PTFE's full suite of properties to prevent insulation failure in your most critical systems.

- Providing Expert Custom Fabrication: From initial prototypes to high-volume production runs, we engineer solutions tailored to your exact electrical, thermal, and chemical requirements.

- Guaranteeing Precision: We prioritize manufacturing accuracy to ensure consistent performance and a perfect fit in your assemblies.

Let's discuss how our PTFE expertise can protect your project. Contact KINTEK today for a consultation on your specific needs.

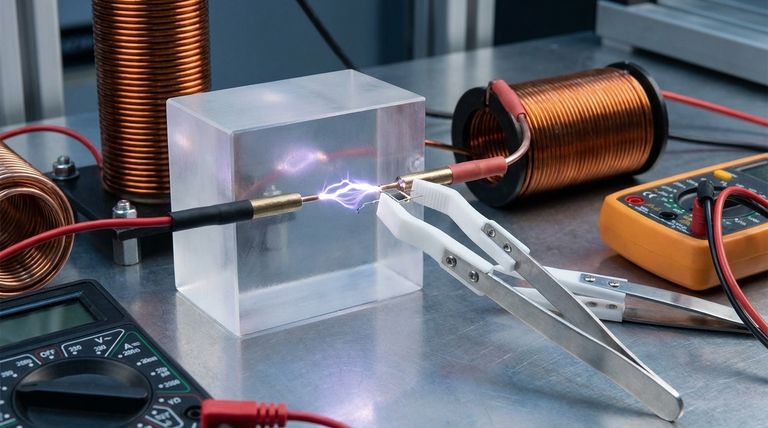

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech