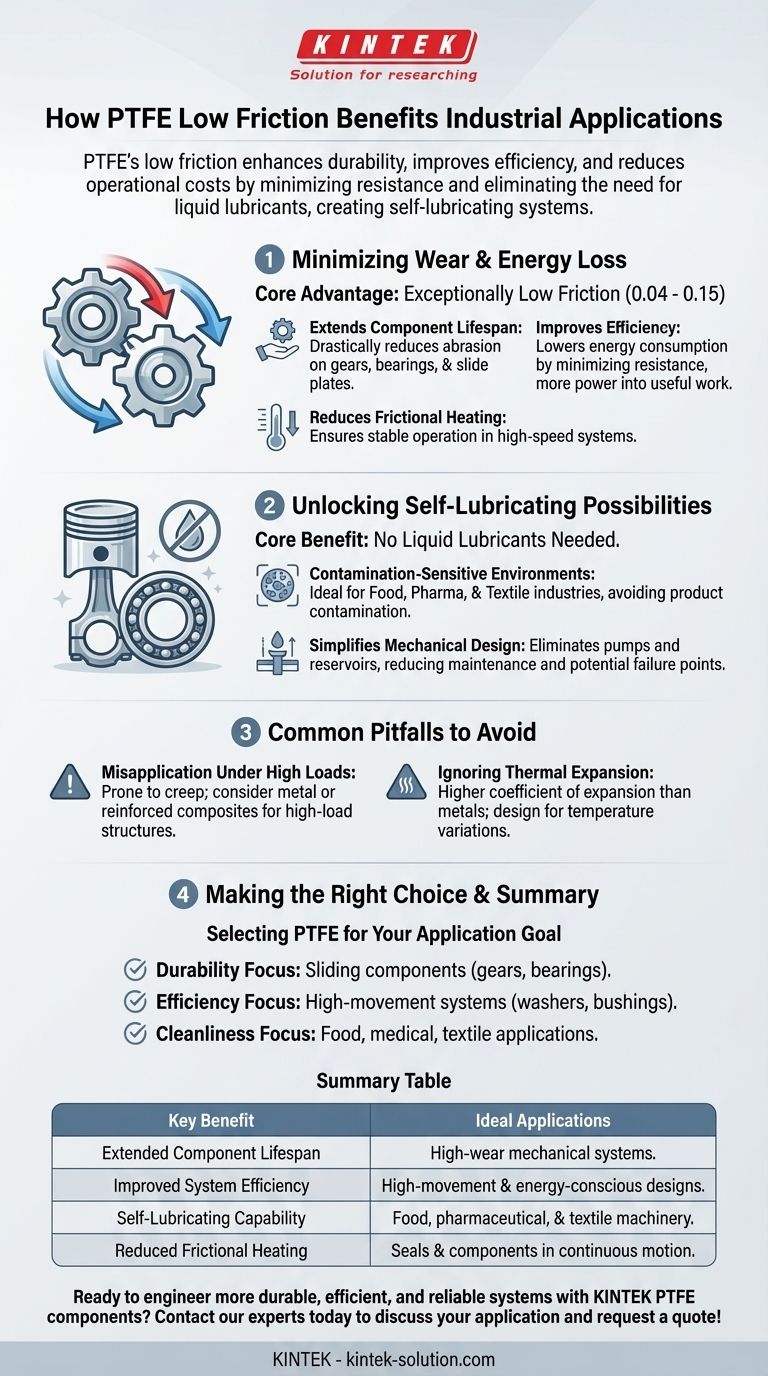

In industrial applications, the low friction of Polytetrafluoroethylene (PTFE) directly translates to enhanced durability, improved efficiency, and reduced operational costs. By minimizing resistance between moving parts, PTFE reduces wear on critical components, lowers energy consumption, and eliminates the need for liquid lubricants in sensitive environments.

The core benefit of PTFE's low friction is not merely its "slipperiness," but its ability to create self-lubricating systems. This allows for more reliable and maintenance-free machinery, especially in industries where traditional lubrication is impossible or undesirable.

The Core Advantage: Minimizing Wear and Energy Loss

The fundamental value of PTFE stems from its exceptionally low coefficient of friction, which is typically between 0.04 and 0.15. This property has a direct and significant impact on the performance and lifespan of mechanical systems.

Extending Component Lifespan

When machine parts slide against each other, friction is the primary cause of wear and material degradation. PTFE drastically reduces this force.

This means components like gears, bearings, and slide plates experience significantly less abrasion, leading to a much longer operational life and reducing the frequency of costly replacements.

Improving System Efficiency

Friction is a source of energy loss. In any mechanical system, energy must be expended to overcome the resistance between moving parts.

By minimizing this resistance, PTFE allows machinery to operate more efficiently. Less energy is wasted as heat, which means more of the input power is converted into useful work, lowering overall energy consumption.

Reducing Frictional Heating

In dynamic, high-speed applications, friction can generate significant heat. This heat can damage components, degrade seals, and negatively impact system performance.

PTFE's low friction minimizes this heat generation, ensuring more stable and reliable operation, particularly for seals and other parts in continuous motion.

Unlocking New Possibilities: The Self-Lubricating Effect

One of the most powerful benefits of PTFE is its ability to function where traditional lubricants cannot. This opens up design possibilities that would be impractical with other materials.

Operating in Contamination-Sensitive Environments

Many industries cannot tolerate the presence of lubricating oils or greases, which can contaminate products.

PTFE is an ideal solution for machinery in the food, pharmaceutical, and textile industries. It provides the necessary low-friction movement for components like piston rings and bearings without introducing contaminants.

Simplifying Mechanical Design

The need for external lubrication often adds complexity and cost to a design, requiring pumps, reservoirs, and regular maintenance.

Using PTFE for parts like bushings and washers can eliminate the need for these systems entirely. This results in a simpler, more reliable design with fewer potential points of failure and lower maintenance costs.

Common Pitfalls to Avoid

While its low friction is a tremendous asset, PTFE is not a universal solution. Understanding its limitations is critical for successful application.

Misapplication Under High Loads

PTFE is a relatively soft material. It can be prone to "creep" or deform under heavy, sustained loads, especially at elevated temperatures.

For high-load structural applications, a metal bearing or a reinforced PTFE composite is often a more suitable choice.

Ignoring Thermal Expansion

Like many polymers, PTFE has a higher coefficient of thermal expansion than metals. This means it will expand and contract more significantly with temperature changes.

Engineers must account for this in their designs to avoid component seizure or failure when operating across a wide temperature range.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on the primary goal of your mechanical system.

- If your primary focus is durability and longevity: Use PTFE for sliding components like gears, bearings, and wear strips to drastically minimize wear.

- If your primary focus is energy efficiency: Incorporate PTFE washers, bushings, and seals in high-movement systems to reduce the energy wasted overcoming friction.

- If your primary focus is operational cleanliness: Choose PTFE for any mechanical part used in food, medical, or textile applications where traditional lubricants are forbidden.

Ultimately, leveraging PTFE's low friction allows you to engineer more durable, efficient, and reliable systems.

Summary Table:

| Key Benefit | Primary Impact | Ideal Applications |

|---|---|---|

| Extended Component Lifespan | Drastically reduces wear on gears, bearings, and slide plates. | High-wear mechanical systems. |

| Improved System Efficiency | Lowers energy consumption by minimizing resistance. | High-movement systems, energy-conscious designs. |

| Self-Lubricating Capability | Eliminates contamination risk from liquid lubricants. | Food, pharmaceutical, and textile machinery. |

| Reduced Frictional Heating | Ensures stable operation in high-speed applications. | Seals and components in continuous motion. |

Ready to engineer more durable, efficient, and reliable systems with PTFE components?

KINTEK specializes in the precision manufacturing of high-performance PTFE components—including seals, liners, bushings, and custom labware. We serve the semiconductor, medical, laboratory, and industrial sectors, providing solutions from prototypes to high-volume production.

Let us help you leverage PTFE's unique properties to solve your specific design challenges. Contact our experts today to discuss your application and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications