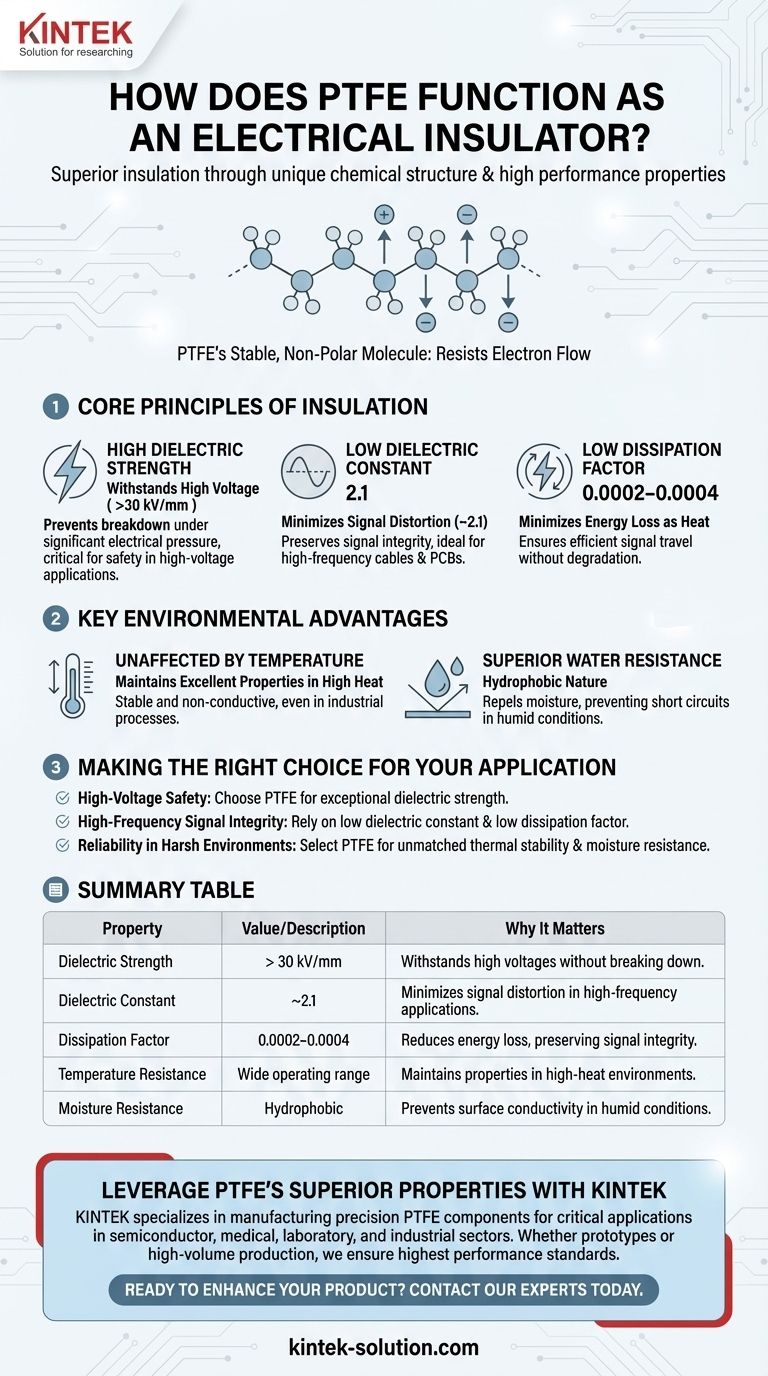

At its core, Polytetrafluoroethylene (PTFE) functions as a superior electrical insulator due to its unique chemical structure. This structure creates an incredibly stable and non-polar molecule that strongly resists the flow of electrons. This inherent resistance is quantified by its high dielectric strength, low dielectric constant, and minimal energy loss, making it a premier material for demanding electrical applications.

The critical takeaway is that PTFE is not merely a barrier to electricity; it is an engineered material that actively preserves the quality and integrity of electrical signals, especially in high-voltage and high-frequency environments where other insulators would fail.

The Core Principles of PTFE Insulation

To understand why PTFE is so effective, we must look beyond the simple label of "insulator" and examine the specific electrical properties that set it apart. These characteristics work in concert to provide safe, stable, and efficient insulation.

A Chemical Structure Built for Resistance

The foundation of PTFE's insulating capability is its molecular makeup. The strong carbon-fluorine bonds create a dense, stable structure that gives electrons no free pathways to travel, effectively stopping electrical current in its tracks.

High Dielectric Strength: The Voltage Barrier

Dielectric strength measures a material's ability to withstand a high voltage before it breaks down and allows current to pass. PTFE possesses an exceptionally high dielectric strength, exceeding 30 kV/mm.

This means it can handle significant electrical pressure without failing, making it an indispensable material for coating high-voltage wires, cables, and critical connectors where safety and reliability are paramount.

Low Dielectric Constant: Preserving Signal Integrity

The dielectric constant indicates how much electrical energy a material can store when subjected to an electric field. PTFE's very low dielectric constant of 2.1 is a significant advantage.

In high-frequency applications, such as coaxial cables or printed circuit boards (PCBs), a low dielectric constant ensures that the insulator does not absorb and distort the electrical signal. This preserves signal integrity for clear and efficient transmission.

Low Dissipation Factor: Minimizing Energy Loss

Closely related to its low dielectric constant, PTFE has an extremely low dissipation factor (around 0.0002–0.0004). This figure represents the amount of a signal's energy that is lost as heat within the insulating material.

PTFE's minimal energy loss ensures that electrical signals travel efficiently without degrading, which is critical for sensitive electronics and high-performance communication systems.

Key Environmental Advantages

An insulator's performance in a controlled lab is one thing; its reliability in a real-world environment is another. PTFE excels here as well, maintaining its superior properties under conditions that would compromise lesser materials.

Unaffected by Temperature

Many electrical components generate heat during operation. PTFE maintains its excellent electrical and dielectric properties over a very wide range of temperatures. This thermal stability ensures it will not degrade or become conductive, even in high-heat industrial processes.

Superior Water Resistance

PTFE is inherently hydrophobic, meaning it repels water. Moisture can create conductive paths on the surface of an insulator, leading to short circuits and system failure. PTFE's resistance to water absorption ensures its insulating properties remain consistent, even in humid or wet environments.

Making the Right Choice for Your Application

Understanding these specific properties allows you to select PTFE with confidence for the right reasons. Your choice depends on which aspect of its performance is most critical to your goal.

- If your primary focus is high-voltage safety: Choose PTFE for its exceptional dielectric strength, which prevents dangerous electrical arcing and material breakdown.

- If your primary focus is high-frequency signal integrity: Rely on PTFE's low dielectric constant and low dissipation factor to ensure signals are transmitted cleanly with minimal loss or distortion.

- If your primary focus is reliability in harsh environments: Select PTFE for its unmatched thermal stability and moisture resistance, guaranteeing consistent performance over time.

Ultimately, leveraging PTFE as an electrical insulator is a decision to prioritize performance, safety, and long-term stability in your design.

Summary Table:

| Property | Value/Description | Why It Matters for Insulation |

|---|---|---|

| Dielectric Strength | > 30 kV/mm | Withstands high voltages without breaking down, ensuring safety and reliability. |

| Dielectric Constant | ~2.1 | Minimizes signal distortion in high-frequency applications like RF cables and PCBs. |

| Dissipation Factor | 0.0002–0.0004 | Reduces energy loss as heat, preserving signal integrity and efficiency. |

| Temperature Resistance | Wide operating range | Maintains insulating properties in high-heat environments without degrading. |

| Moisture Resistance | Hydrophobic | Prevents surface conductivity and short circuits in humid or wet conditions. |

Leverage PTFE's Superior Insulating Properties for Your Critical Applications

PTFE is the material of choice when your designs demand uncompromising electrical insulation, signal integrity, and reliability in harsh conditions. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom fabricated parts—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need prototypes or high-volume production, our expertise ensures your components meet the highest standards of performance.

Ready to enhance your product's performance with precision PTFE insulation? Contact our experts today to discuss your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech