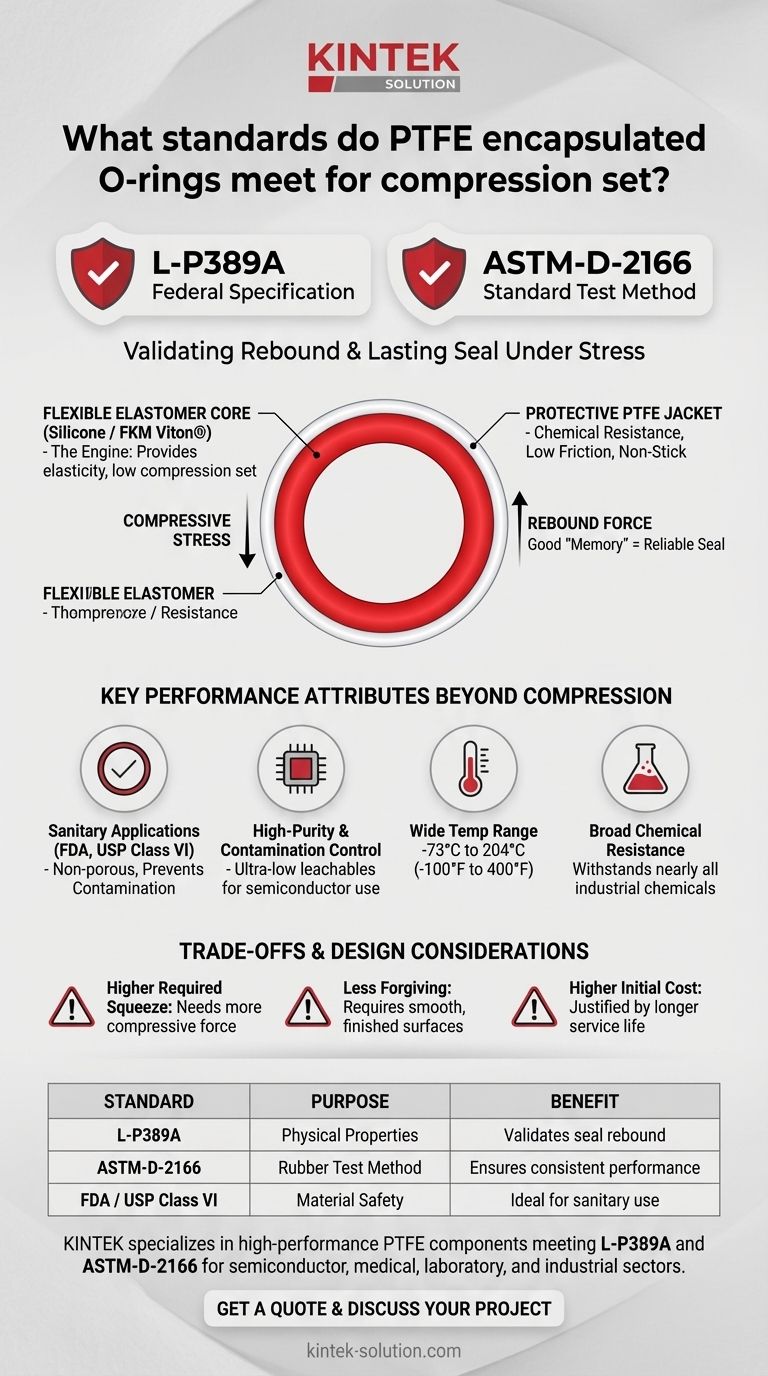

To be clear, PTFE encapsulated O-rings are engineered to meet or exceed the compression set requirements of two key standards: L-P389A and ASTM-D-2166. These standards validate the seal's ability to rebound after being compressed, ensuring a reliable and lasting seal under operational stress.

The core takeaway is that compliance with these standards isn't just a specification—it's proof of a sophisticated design that combines the elasticity of a rubber core with the resilience and chemical inertness of a PTFE jacket.

The Role of Compression Set and Its Standards

Understanding compression set is critical for any sealing application. It is the measure of a material's permanent deformation after being subjected to prolonged compressive stress at a given temperature.

What Compression Set Tells You

A low compression set value is desirable. It indicates that the O-ring material has good "memory" and will continue to exert a sealing force after the initial installation.

A high compression set value signifies that the seal has permanently flattened and lost its ability to rebound, which inevitably leads to leaks and seal failure.

L-P389A and ASTM-D-2166 Explained

These are not just arbitrary numbers; they are established benchmarks for performance.

L-P389A is a federal specification, while ASTM-D-2166 is a standard test method from ASTM International. Both provide standardized procedures for testing the physical properties of sealing compounds, ensuring consistency and reliability across manufacturers.

Meeting these standards confirms that the O-ring can withstand the mechanical stresses required for a dependable seal in demanding environments.

The Engineering Behind the Performance

The superior performance of a PTFE encapsulated O-ring comes from its hybrid construction. It leverages the strengths of two different materials to overcome their individual limitations.

The Flexible Elastomer Core

The inner core, typically made of Silicone or FKM (Viton®), provides the flexibility and elasticity. This is the "engine" of the seal, responsible for providing the constant outward force needed to maintain a seal and achieve a low compression set.

The Protective PTFE Jacket

The outer encapsulation is a thin jacket of PTFE. This layer provides exceptional chemical resistance, a low coefficient of friction (as low as 0.2), and a non-stick, sanitary surface.

The key manufacturing challenge is to seamlessly bond this jacket to the core without compromising the core's ability to flex and rebound. Adherence to strict quality standards is what makes this possible.

Beyond Compression: Key Performance Attributes

While meeting compression set standards is crucial, engineers choose these seals for a wider range of benefits, particularly in sensitive or aggressive applications.

Suitability for Sanitary Applications

PTFE encapsulated O-rings are often compliant with FDA and USP Class VI standards. The PTFE jacket is non-porous and prevents the elastomer core from contaminating process fluids, making them ideal for pharmaceutical, food and beverage, and biomedical industries.

High-Purity and Contamination Control

For industries like semiconductor manufacturing, material purity is paramount. These O-rings can be produced with extremely low levels of leachable metals, such as lead (below 10^-11 g/ml), ensuring process integrity.

Wide Temperature and Chemical Range

The PTFE jacket allows these seals to operate in temperatures from -73°C to 204°C (-100°F to 400°F) and withstand nearly all industrial chemicals, a feat that is impossible for most single-elastomer O-rings.

Understanding the Trade-offs

No sealing solution is perfect for every scenario. Being an effective advisor means acknowledging the limitations and design considerations.

Higher Required Squeeze

The PTFE jacket is inherently stiffer than a standard elastomer. Consequently, encapsulated O-rings typically require a higher compressive force (more "squeeze") to achieve a proper seal in the groove. This must be accounted for during the design phase.

Less Forgiving on Surfaces

Because of this same stiffness, the PTFE jacket is less able to conform to minor imperfections like scratches or nicks in a sealing surface. A smooth, well-finished groove is essential for optimal performance.

Higher Initial Cost

The multi-step, precision manufacturing process makes PTFE encapsulated O-rings more expensive than standard nitrile or silicone O-rings. However, this cost is often justified by increased service life and reduced downtime in aggressive environments.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching its properties to your application's primary demand.

- If your primary focus is extreme chemical resistance or high-purity: A PTFE encapsulated O-ring is an excellent choice, providing a nearly universal solution.

- If your primary focus is sealing in a low-force application or on a slightly imperfect surface: A high-performance, single-elastomer O-ring (like an FKM or FFKM) may provide a more compliant seal.

- If your primary focus is a general-purpose application with a limited budget: A standard nitrile or EPDM O-ring is likely the more cost-effective and appropriate solution.

Ultimately, knowing that a seal meets critical standards like L-P389A and ASTM-D-2166 provides the assurance you need to build a reliable and resilient system.

Summary Table:

| Key Standard | Purpose | Benefit |

|---|---|---|

| L-P389A | Federal specification for physical properties | Validates seal rebound and lasting performance |

| ASTM-D-2166 | Standard test method for rubber properties | Ensures consistent, reliable performance across manufacturers |

| FDA / USP Class VI | Standards for material safety and purity | Ideal for sanitary, pharmaceutical, and biomedical applications |

Need a reliable seal that withstands aggressive chemicals and high temperatures?

KINTEK specializes in manufacturing high-performance PTFE components, including precision PTFE encapsulated O-rings. Our seals are engineered to meet stringent standards like L-P389A and ASTM-D-2166, ensuring exceptional compression set resistance, chemical inertness, and long-term reliability for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, tailoring solutions to your exact specifications. Contact us today to discuss your sealing challenges and let our expertise enhance your system's performance and durability.

Get a Quote & Discuss Your Project

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the advantages of using PTFE for spring-energized seal jackets? Superior Performance in Extreme Conditions

- What are the water absorption and flammability characteristics of PTFE? Unmatched Stability for Harsh Environments

- How do PTFE seals enhance sealing performance in ball valves? Achieve Superior, Leak-Proof Sealing

- What advantages do PTFE rotary shaft seals offer in high-speed applications? Unlock Superior Speed and Reliability

- What makes PTFE suitable for lining butterfly valves? Unlock Superior Corrosion Resistance and Purity

- What are PTFE piston seals commonly known as? The Critical Role of Teflon™ Seals in High-Performance Applications

- What is the temperature rating for PTFE gaskets? Maximize Performance from -200°C to 260°C

- Why is Teflon gland packing considered a future-proof solution for industrial sealing systems? Unmatched Chemical & Thermal Resilience