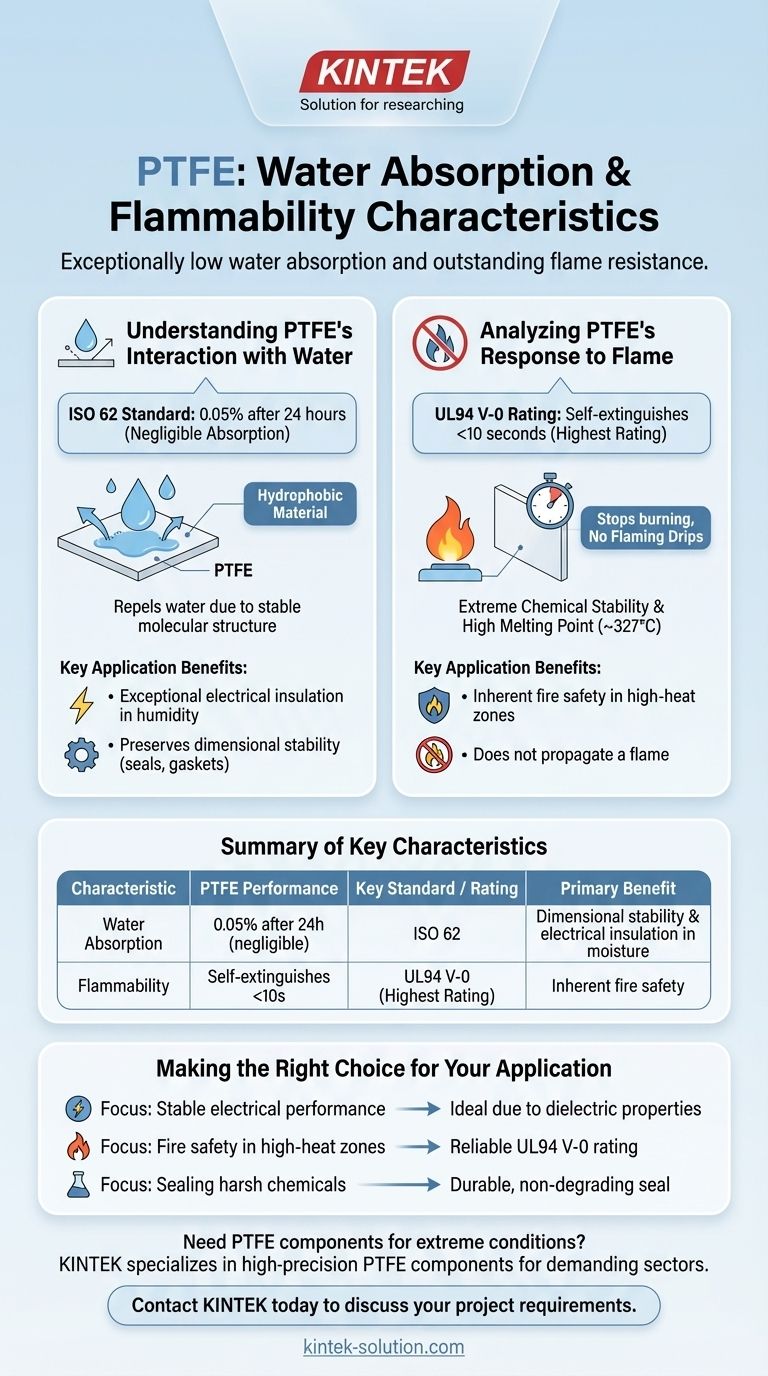

In short, Polytetrafluoroethylene (PTFE) exhibits exceptionally low water absorption and outstanding flame resistance. Its water absorption rate is a mere 0.05% after 24 hours of immersion, and it achieves the highest possible UL94 V-0 rating for flammability, meaning it self-extinguishes almost immediately after a flame source is removed.

These two characteristics are not isolated features but are direct consequences of PTFE's incredibly stable molecular structure. This inherent chemical inertness is what makes PTFE a default material choice for applications in harsh, demanding, or safety-critical environments.

Understanding PTFE's Interaction with Water

PTFE's performance in the presence of moisture is a key reason for its widespread use in electronics, sealing, and fluid handling. Its behavior is consistent and highly predictable.

The Technical Specification (ISO 62)

According to the ISO 62 standard, PTFE demonstrates a water absorption rate of just 0.05% after 24 hours and 0.1% after 96 hours at 23°C.

For all practical purposes in engineering, this level of absorption is considered negligible. It does not swell, soften, or change its dimensions when exposed to water or high humidity.

The Reason: Inherent Hydrophobicity

PTFE is a hydrophobic material, meaning it actively repels water. This property arises from its unique molecular structure, which is composed of a long chain of carbon atoms completely shielded by fluorine atoms.

This fluorine sheath creates a very low-energy surface that water cannot easily "wet," causing droplets to bead up and run off rather than being absorbed.

Key Application Benefits

This near-zero water absorption is critical for performance. It ensures that PTFE maintains its exceptional electrical insulation properties even in damp or humid conditions, as water is not absorbed to create conductive paths.

Furthermore, its dimensional stability is preserved, which is vital for components like seals, gaskets, and bearings that require tight tolerances.

Analyzing PTFE's Response to Flame

PTFE is widely recognized as a non-flammable material. It does not support combustion and will not propagate a flame.

The Official Rating (UL94 V-0)

PTFE is rated UL94 V-0. This is the highest and most favorable classification under this widely used safety standard.

A V-0 rating means that when a sample is exposed to a flame and the flame is removed, the material will stop burning on its own within 10 seconds and will not produce flaming drips that could ignite other materials below.

The Reason: Extreme Chemical Stability

PTFE does not readily combust because of the immense strength of its carbon-fluorine bonds. It requires a tremendous amount of energy to break these bonds.

It has an extremely high melting point (around 327°C) and does not ignite easily. It is considered incombustible and will not act as a fuel source in a fire.

Understanding the Trade-offs

While its resistance to water and flame is elite, it's crucial to see PTFE as a complete material system with inherent limitations.

A Suite of High-Performance Traits

The same chemical stability that provides water and fire resistance also gives PTFE its other famous characteristics: near-universal chemical inertness, an extremely low coefficient of friction, and a wide operating temperature range (from -200°C to +260°C).

A Key Limitation: Mechanical Properties

PTFE is not a mechanically robust material. It has relatively low tensile strength and is susceptible to creep (deformation under sustained load).

Its non-stick, low-energy surface also makes it extremely difficult to bond to other materials using conventional adhesives. This must be accounted for in component design.

Making the Right Choice for Your Application

Selecting PTFE is a decision based on its unique combination of resistances. Use this guide to determine if it fits your primary goal.

- If your primary focus is stable electrical performance: PTFE is an ideal choice, as its dielectric properties are unaffected by humidity or direct water contact.

- If your primary focus is fire safety in high-heat zones: Its UL94 V-0 rating and inherent incombustibility provide a reliable safety factor.

- If your primary focus is sealing harsh chemicals or solvents: PTFE's dual resistance to chemical attack and water absorption ensures a durable, non-degrading seal.

Ultimately, specifying PTFE is a strategic choice for environments where reliability against heat, chemicals, and moisture cannot be compromised.

Summary Table:

| Characteristic | PTFE Performance | Key Standard / Rating |

|---|---|---|

| Water Absorption | 0.05% after 24 hours (negligible) | ISO 62 |

| Flammability | Self-extinguishes within 10 seconds | UL94 V-0 (Highest Rating) |

| Primary Benefit | Dimensional stability & electrical insulation in moisture; inherent fire safety. | - |

Need PTFE components that guarantee performance under extreme conditions?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get parts with the critical water and flame resistance your application demands.

Contact KINTEK today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industries commonly use PTFE expansion joints and why? Solve Critical Pipeline Challenges with PTFE

- Can PTFE butterfly valves be used for all types of fluids? Maximize Chemical Resistance and Purity

- What are the main benefits of PTFE envelope gaskets? Achieve Superior Chemical Resistance and Sealing Integrity

- What are the two main methods for producing PTFE? Choose the Right Path for Your Application

- What are spring-energized seals, and why are they used in extreme environments?

- What are the symptoms of temperature-induced seal failure? Diagnose Leaks and Prevent Downtime

- What makes Teflon gland packing superior to other types? Unmatched Chemical Resistance & Low Friction

- How does molybdenum disulfide (MoS2) enhance PTFE? Boost Hardness, Wear Resistance & Durability