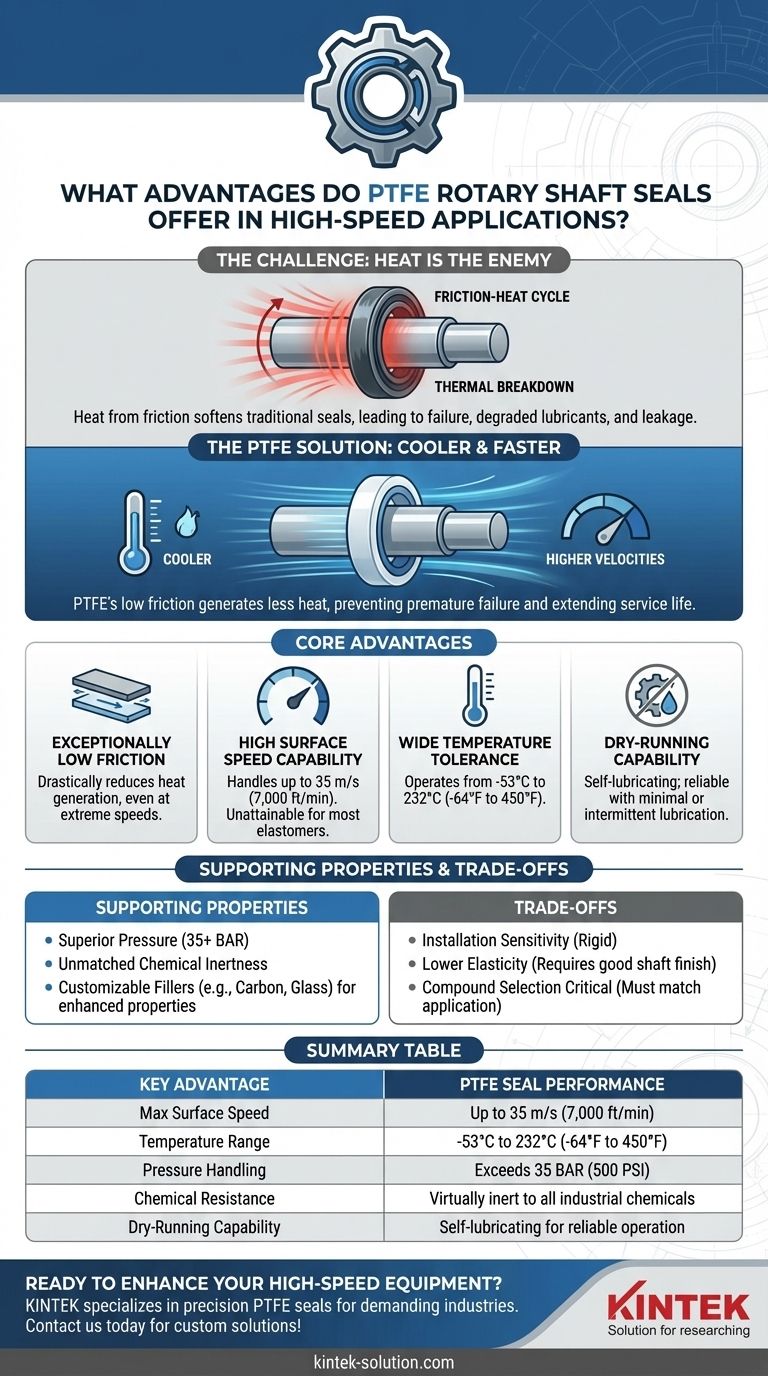

At their core, PTFE rotary shaft seals excel in high-speed applications because their incredibly low friction generates significantly less heat than traditional elastomeric seals. This fundamental advantage prevents the thermal breakdown that causes premature failure, allowing machinery to operate at higher rotational velocities (up to 35 m/s) while dramatically extending the seal's service life.

The central challenge in any high-speed sealing application is managing destructive heat caused by friction. PTFE directly solves this problem by running cooler and faster, transforming a common point of failure into a component of long-term reliability.

Why Heat is the Enemy of High-Speed Sealing

In any rotating system, the contact between the seal lip and the shaft is a source of friction. At high speeds, this friction can quickly become a critical problem, leading to a cascade of failures.

The Friction-Heat Cycle

Traditional rubber seals press firmly against the shaft to prevent leaks. As speed increases, this contact generates significant frictional heat.

This heat softens the seal material, increasing the contact patch and creating even more friction. This vicious cycle causes temperatures to rise rapidly.

How Heat Degrades Materials

Excessive heat causes elastomeric (rubber) seals to harden, crack, and lose their flexibility. A brittle seal can no longer conform to the shaft surface, resulting in catastrophic leakage.

The Impact on Lubricants

High temperatures can also degrade the lubricant at the sealing point. This breakdown of the oil or grease film eliminates the barrier between the seal and shaft, accelerating wear on both components.

The Core Advantages of PTFE in High-Speed Environments

PTFE (polytetrafluoroethylene) possesses a unique combination of properties that directly counteracts the challenges of high-speed rotation. It isn't just one feature, but the synergy of several that makes it the superior choice.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This is its primary advantage, as it drastically reduces the amount of heat generated at the seal-shaft interface, even at extreme speeds.

High Surface Speed Capability

Because they run cooler, PTFE seals can handle shaft surface speeds up to 35 m/s (approx. 7,000 ft/min). This is a threshold that is simply unattainable for most standard elastomer seals.

Wide Temperature Tolerance

PTFE maintains its integrity across an exceptionally broad temperature range, typically from -53°C to 232°C (-64°F to 450°F). This high heat resistance ensures it remains stable and effective even when ambient or operational temperatures are high.

Dry-Running Capability

The self-lubricating nature of PTFE allows it to perform reliably even with minimal lubrication. This is a critical advantage during startup phases before lubrication is fully established or in applications where lubrication is intermittent.

Beyond Speed: Supporting Properties for Demanding Applications

High speed is often accompanied by other extreme conditions. PTFE's robust characteristics provide reliability across multiple performance vectors simultaneously.

Superior Pressure Handling

Specialized PTFE seal designs can effectively manage pressures exceeding 35 BAR (500 PSI). This makes them ideal for applications where high velocity and high pressure coexist.

Unmatched Chemical Inertness

PTFE is virtually inert to all industrial chemicals and fluids. This allows it to be used with aggressive lubricants or in corrosive environments without risk of material degradation.

Customizable with Fillers

PTFE's base properties can be enhanced by adding fillers like carbon, graphite, or glass fiber. These compounds improve wear resistance, stiffness, and compressive strength, tailoring the seal for the specific demands of the application.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. An objective assessment requires understanding its specific characteristics and limitations to ensure proper application.

Installation Sensitivity

PTFE seals are more rigid than their elastomer counterparts. They have less "stretch" and require careful handling and proper installation tools to avoid nicking or damaging the critical sealing lip.

Lower Elasticity

Unlike rubber, PTFE has limited elastic memory. It is less forgiving of shaft imperfections, such as significant runout or scoring. Proper shaft surface finish and geometry are crucial for optimal performance.

Compound Selection is Critical

The term "PTFE" covers a wide range of filled compounds. Choosing the wrong filler can negatively impact performance. For example, a filler that boosts wear resistance might slightly reduce chemical compatibility, so selection must be matched precisely to the application's needs.

Making the Right Choice for Your Application

Selecting the correct seal material is about aligning its properties with your primary operational goal.

- If your primary focus is maximizing rotational speed: PTFE is the definitive choice due to its low-friction characteristics that minimize destructive heat buildup.

- If you are dealing with aggressive chemicals or extreme temperatures in addition to speed: PTFE's chemical inertness and wide thermal range make it the most reliable option.

- If your application requires both high pressure and high velocity: PTFE seals are engineered to handle these combined stresses where most other materials would fail.

- If your equipment operates with minimal or intermittent lubrication: The self-lubricating, dry-running capability of PTFE provides a crucial safety margin against premature wear.

By understanding its full performance profile, you can leverage PTFE to achieve superior levels of speed, reliability, and longevity in your most critical rotary applications.

Summary Table:

| Key Advantage | PTFE Seal Performance |

|---|---|

| Max Surface Speed | Up to 35 m/s (7,000 ft/min) |

| Temperature Range | -53°C to 232°C (-64°F to 450°F) |

| Pressure Handling | Exceeds 35 BAR (500 PSI) |

| Chemical Resistance | Virtually inert to all industrial chemicals |

| Dry-Running Capability | Self-lubricating for reliable operation with minimal lubrication |

Ready to enhance your high-speed equipment with reliable PTFE sealing solutions?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for demanding industries like semiconductor, medical, and industrial manufacturing. Our expertise in custom fabrication ensures you get the exact seal performance needed for your high-speed applications, from prototypes to high-volume orders.

Contact us today to discuss how our PTFE rotary shaft seals can deliver superior speed, longevity, and reliability for your machinery. Get in touch via our contact form for a personalized solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications