In the most demanding sealing environments, Polytetrafluoroethylene (PTFE) is the premier choice for spring-energized seal jackets due to its unique combination of properties. Its core advantages are an exceptionally wide operating temperature range, near-universal chemical inertness, and a very low coefficient of friction, making it reliable where conventional elastomers would quickly fail.

The fundamental advantage isn't just PTFE's inherent properties, but how these properties work in synergy with a spring energizer. This combination creates a robust sealing system that maintains a consistent, reliable force against the hardware across extreme temperatures, high pressures, and dynamic conditions.

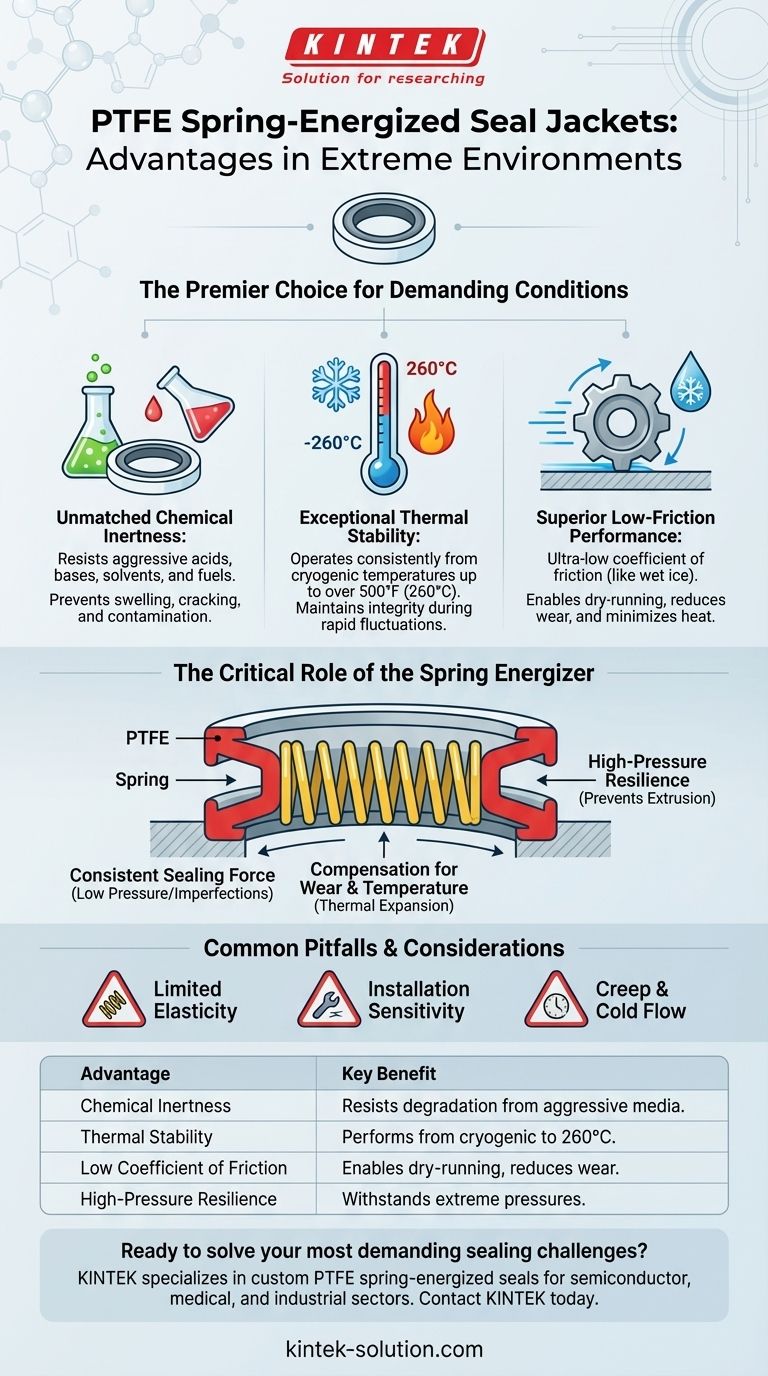

Why PTFE Excels in Extreme Conditions

The selection of a seal material is dictated by the environment it must withstand. PTFE's molecular structure gives it a set of characteristics that make it uniquely suited for the most challenging applications.

Unmatched Chemical Inertness

PTFE is virtually inert and resists degradation from the most aggressive chemicals, including strong acids, bases, solvents, and fuels.

This prevents the seal from swelling, cracking, or breaking down, ensuring both the integrity of the seal and the purity of the media it contains.

Exceptional Thermal Stability

The material maintains its properties and structural integrity across a vast temperature range, from cryogenic conditions up to over 500°F (260°C).

This thermal stability ensures a consistent and predictable sealing performance, even during rapid temperature fluctuations where other materials would become brittle or lose their shape.

Superior Low-Friction Performance

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This property is critical in dynamic (moving) applications, as it reduces wear, minimizes heat generation, and allows for smooth operation without lubrication, a capability often referred to as dry-running.

The Critical Role of the Spring Energizer

A ring of PTFE alone is not an effective seal because it lacks elasticity. The spring energizer is the component that transforms the PTFE jacket into a high-performance sealing solution.

Consistent Sealing Force

The spring provides a continuous, live outward force, pressing the PTFE lips firmly against the sealing surfaces.

This constant force ensures a tight seal even at low pressures and compensates for any minor hardware imperfections.

Compensation for Wear and Temperature

As the PTFE jacket slowly wears over its service life, the spring expands to fill the gap, maintaining a consistent sealing pressure.

It also compensates for dimensional changes in the seal and hardware caused by thermal expansion and contraction, a common point of failure for standard elastomeric seals.

High-Pressure Resilience

The combination of the strong PTFE jacket and the mechanical force from the spring allows the seal to withstand extremely high pressures without being extruded or damaged.

Common Pitfalls and Considerations

While highly effective, a PTFE spring-energized seal is a specialized component. Understanding its limitations is key to successful implementation.

Limited Elasticity

PTFE has poor "elastic memory" compared to rubber. It will not rebound to its original shape after being compressed, which is precisely why the spring is essential.

Without the spring, a PTFE ring would offer minimal sealing capability.

Installation Sensitivity

Due to their relative rigidity compared to O-rings, PTFE seals can be more challenging to install. Care must be taken to avoid scratching the seal jacket or the hardware, as any damage can create a leak path.

Creep and Cold Flow

Under a constant load, PTFE can be subject to "creep" or cold flow. The design of the seal and the inclusion of fillers in the PTFE blend are engineered to mitigate this, but it remains a core material consideration.

Making the Right Choice for Your Application

Selecting the right seal depends entirely on the operational demands of your system.

- If your primary focus is aggressive chemicals or extreme temperatures: PTFE is the default choice, as it provides a level of resistance that elastomers cannot match.

- If your primary focus is purity for medical or food-grade use: FDA-compliant grades of PTFE are ideal due to their inertness, non-outgassing properties, and ability to withstand sterilization processes.

- If your primary focus is high-speed dynamic sealing: The low-friction, dry-running capability of PTFE reduces wear and increases the operational life and efficiency of your equipment.

Ultimately, choosing a PTFE spring-energized seal is a decision to prioritize long-term reliability in environments where failure is not an option.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Inertness | Resists degradation from aggressive acids, bases, and solvents. |

| Thermal Stability | Performs from cryogenic temperatures up to 500°F (260°C). |

| Low Coefficient of Friction | Enables dry-running, reduces wear, and minimizes heat generation. |

| High-Pressure Resilience | Withstands extreme pressures without extrusion when combined with a spring energizer. |

Ready to solve your most demanding sealing challenges?

KINTEK specializes in the precision manufacturing of custom PTFE components, including spring-energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our seals are engineered for reliability where failure is not an option.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and superior performance for your specific application.

Contact KINTEK today to discuss your sealing requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments