From non-stick pans to advanced surgery, the same material known for its slick surface has become a cornerstone in modern medicine. Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, is used extensively for medical applications ranging from permanent implants like artificial heart valves and bones to coatings for surgical instruments, catheters, and durable sutures. Its value comes from a unique combination of properties that make it highly compatible with the human body.

Teflon's role in medicine is not due to a single feature, but its powerful combination of properties. Its profound chemical inertness prevents reactions with body tissues, while its extremely low-friction surface is ideal for devices that must move smoothly and safely within the body.

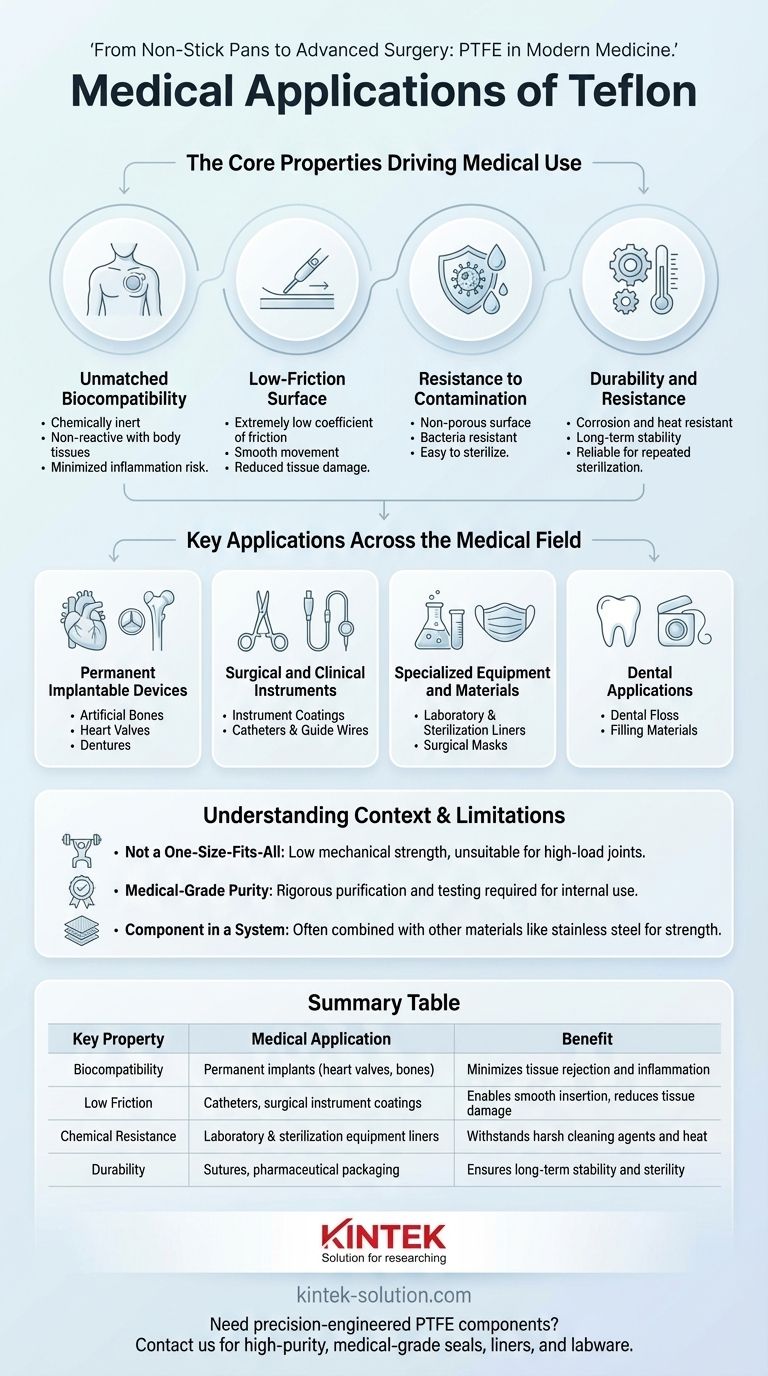

The Core Properties Driving Medical Use

The medical applications of Teflon are a direct result of its fundamental chemical and physical characteristics. Engineers and doctors choose it when specific performance criteria are non-negotiable.

Unmatched Biocompatibility

The primary reason Teflon is used for implants is its biocompatibility. It is one of the most chemically inert materials known.

This means it does not react with bodily fluids or tissues, significantly reducing the risk of inflammation, rejection, or allergic reaction. This property makes it a trusted material for long-term internal use.

A Low-Friction Surface

Teflon possesses one of the lowest coefficients of friction of any solid. This "non-stick" quality is critical for applications where smooth movement is required.

It is used to coat catheters and guide wires, allowing them to be inserted into blood vessels with minimal tissue damage. This same property makes it an excellent coating for surgical instruments.

Resistance to Contamination

The non-porous and non-reactive surface of Teflon is inherently resistant to bacteria. This makes it easier to sterilize and maintain a clean surface.

For this reason, it is used in pharmaceutical packaging, wound dressings, and as a coating on sterilization equipment where preventing contamination is paramount.

Durability and Resistance

Teflon is highly resistant to corrosion and can withstand high temperatures. This durability is essential for medical devices that must be sterilized repeatedly using heat or harsh chemicals.

It also ensures the long-term stability of permanent implants and the reliability of sutures that must hold tissues together without degrading over time.

Key Applications Across the Medical Field

These core properties translate into a wide array of specific uses across different medical disciplines.

Permanent Implantable Devices

Because the body does not reject it, Teflon is used to create or repair artificial body parts. Common examples include artificial bones, heart valves, and dentures, where long-term stability and non-reactivity are essential.

Surgical and Clinical Instruments

The lubricity of Teflon is leveraged to improve the performance and safety of many clinical tools. It serves as a coating on surgical instruments to reduce friction and is a key material in constructing catheters that navigate delicate internal structures.

Specialized Equipment and Materials

Beyond direct patient contact, Teflon's durability is vital for hospital infrastructure. It is used to line laboratory and sterilization equipment due to its resistance to heat and corrosive chemicals. Its flame-retardant properties are even used in some surgical masks.

Dental Applications

In dentistry, Teflon's inertness and non-stick properties are valuable. It is found in some types of dental floss that glide easily between teeth and has been used in certain filling materials.

Understanding the Context and Limitations

While its properties are exceptional, Teflon is not a universal solution. Its selection is a deliberate engineering choice based on specific needs.

Not a One-Size-Fits-All Material

Teflon is prized for its inertness and low friction, but not for its mechanical strength. For high-load applications like major joint replacements, other materials like titanium and specialized polymers are often preferred for their structural integrity.

The Importance of Medical-Grade Purity

The Teflon used in a medical implant is not the same as the material in cookware. Medical-grade PTFE undergoes rigorous purification and testing processes to ensure it meets strict safety and quality standards required for use inside the human body.

A Component in a Larger System

In many applications, Teflon works in concert with other materials. An instrument might have a stainless steel core for strength and a Teflon coating for a smooth surface, combining the best properties of each material to achieve the desired outcome.

Making the Right Choice for Your Goal

Understanding Teflon's role helps contextualize its importance in healthcare technology.

- If your primary focus is patient safety: Understand that medical-grade Teflon is chosen specifically because its non-reactive nature minimizes the risk of adverse reactions inside the body.

- If your primary focus is engineering and design: Recognize Teflon (PTFE) as a specialized polymer valued for its unique combination of lubricity and biocompatibility, making it ideal for coatings and low-load implants.

- If your primary focus is general knowledge: See Teflon as a prime example of how a material's fundamental properties can be leveraged to solve critical challenges in fields far beyond its original intent.

Ultimately, Teflon's success in medicine is a clear demonstration of how material science can be harnessed to improve and save human lives.

Summary Table:

| Key Property | Medical Application | Benefit |

|---|---|---|

| Biocompatibility | Permanent implants (heart valves, bones) | Minimizes tissue rejection and inflammation |

| Low Friction | Catheters, surgical instrument coatings | Enables smooth insertion, reduces tissue damage |

| Chemical Resistance | Laboratory & sterilization equipment liners | Withstands harsh cleaning agents and heat |

| Durability | Sutures, pharmaceutical packaging | Ensures long-term stability and sterility |

Need precision-engineered PTFE components for your medical or industrial applications? KINTEK specializes in manufacturing high-purity, medical-grade PTFE seals, liners, labware, and custom components for the semiconductor, medical, and laboratory industries. From prototypes to high-volume orders, we ensure the biocompatibility, durability, and performance your projects demand. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What makes PTFE lined vials easy to clean? The Science Behind Their Non-Stick, Inert Surface

- What are the advantages of PTFE shovels over metal shovels? Precision Handling for Sensitive Materials

- What are the key properties of PTFE that make it suitable for labware applications? Ensure Lab Integrity with Superior Material

- What are the advantages of using PTFE lined chromatography vials? Ensure Sample Integrity & Accurate Results

- Why are PTFE-layered septa used in high-performance applications? Ensure Sample Integrity & Accuracy

- What are the sealing and barrier properties of PTFE-lined bottle caps? Ensure Sample Integrity with Superior Protection

- What are the benefits of using a PTFE safety cover? Enhance Safety, Cut Costs & Mitigate Hazards

- What are the key applications of the PTFE bottle? Ensure Chemical Safety and Sample Purity