The remarkable ease of cleaning PTFE-lined vials stems directly from the unique chemical properties of Polytetrafluoroethylene (PTFE). This material creates an exceptionally non-stick and chemically inert surface, preventing substances from adhering to the vial walls. This quality facilitates a quick and thorough cleaning process, which is critical for preparing vials for subsequent analyses without fear of contamination.

The core reason PTFE-lined vials are easy to clean is their low-energy, non-stick surface. This characteristic not only simplifies the physical cleaning process but also enhances analytical accuracy by minimizing sample carryover and ensures long-term durability.

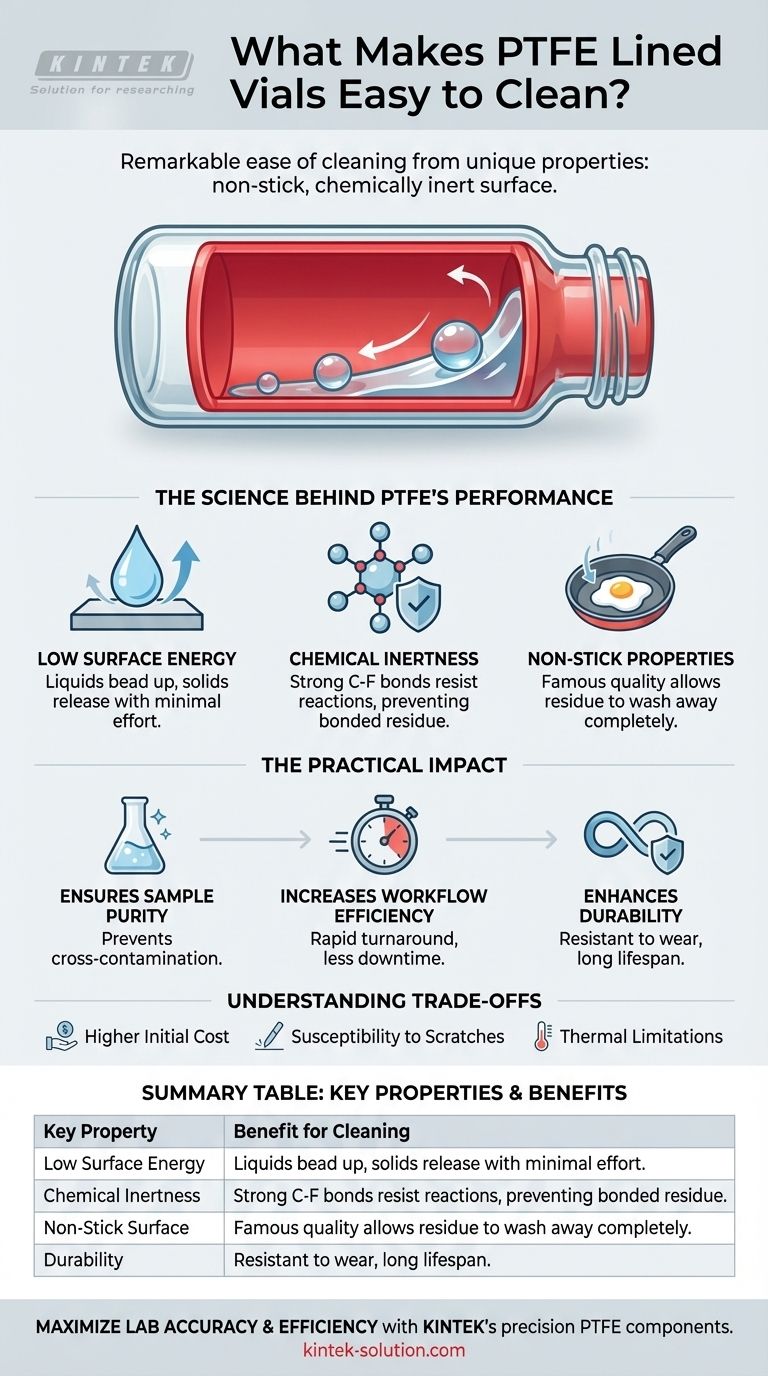

The Science Behind PTFE's Performance

To understand why these vials are so efficient, we must look at the molecular properties of the PTFE lining itself. The benefits are not accidental; they are a direct result of its chemical structure.

Low Surface Energy

PTFE possesses one of the lowest surface energies of any known solid. This means there is very little adhesive force available for other molecules to "grab onto," causing liquids to bead up and solids to release with minimal effort.

Chemical Inertness

The bond between carbon and fluorine atoms in PTFE is exceptionally strong and stable. This makes the material chemically inert, meaning it won't react with the vast majority of chemicals, acids, or bases. Because it doesn't react with the sample, no chemical bonds are formed that would cause residue to stick.

Non-Stick Properties

The combination of low surface energy and chemical inertness results in the famous non-stick quality associated with materials like Teflon®. Residue from previous samples has little to cling to, allowing it to be washed away completely with a simple rinse.

The Practical Impact on Lab Work

The scientific properties of PTFE translate directly into tangible benefits that streamline laboratory workflows and improve the quality of results.

Ensuring Sample Purity

The primary benefit of an easy-to-clean vial is the prevention of cross-contamination. When a vial is truly clean, you can be confident that your results reflect your current sample, not trace remnants of a previous one.

Increasing Workflow Efficiency

Labs focused on high throughput depend on rapid turnaround. The ability to quickly and effectively clean vials means less downtime between analyses, allowing for more tests to be completed in less time.

Enhancing Durability and Lifespan

As noted, PTFE is highly resistant to chemical attack and physical wear. This durability means the vials can withstand repeated, rigorous cleaning cycles over a long period, providing a cost-effective solution compared to less robust alternatives.

Understanding the Trade-offs

While highly effective, it is important to approach any material choice with a clear understanding of its potential limitations.

Higher Initial Cost

PTFE-lined vials typically have a higher upfront cost than standard glass or single-use plastic vials. This investment must be weighed against the long-term savings from reusability and reduced sample loss.

Susceptibility to Scratches

While chemically durable, the PTFE lining can be scratched by sharp or highly abrasive tools. A compromised surface can lose its non-stick properties and create sites where residue can become trapped.

Thermal Limitations

PTFE has a defined upper-temperature limit. For most analytical applications, this is not an issue, but it cannot be subjected to the extreme temperatures that borosilicate glass can withstand, such as in pyrolysis.

Making the Right Choice for Your Application

Selecting the right vial depends entirely on the priorities of your work.

- If your primary focus is analytical accuracy: The non-stick, inert surface of PTFE is invaluable for preventing sample carryover and ensuring the purity of your results.

- If your primary focus is high-throughput efficiency: The rapid and effortless cleaning process significantly reduces vial preparation time, maximizing lab productivity.

- If your primary focus is long-term cost-effectiveness: The exceptional durability and reusability of these vials can provide a lower total cost of ownership compared to disposable alternatives.

Ultimately, choosing PTFE-lined vials is an investment in the reliability, speed, and integrity of your analytical process.

Summary Table:

| Key Property | Benefit for Cleaning |

|---|---|

| Low Surface Energy | Prevents sample adhesion; residue beads up and rinses away easily. |

| Chemical Inertness | Resists reaction with harsh chemicals, preventing bonded residue. |

| Non-Stick Surface | Eliminates sample carryover, ensuring a thorough clean with minimal effort. |

| Durability | Withstands repeated cleaning cycles, providing long-term value. |

Maximize your lab's accuracy and efficiency with KINTEK's precision PTFE components.

Are you struggling with sample carryover or time-consuming vial cleaning? KINTEK specializes in manufacturing high-quality, custom PTFE seals, liners, and labware—including vials—for the semiconductor, medical, laboratory, and industrial sectors. Our components are engineered for superior non-stick performance and chemical resistance, ensuring your samples remain pure and your workflow stays efficient.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications. Let us provide you with the reliable, easy-to-clean solutions your lab needs.

Contact KINTEK today to discuss your application and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are the advantages of PTFE shovels in terms of chemical resistance? Unmatched Inertness for Handling Corrosives

- What specifications do PTFE filters meet for polychlorobenzenes? Ensure Compliance with NIOSH Method 5517

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware

- How does the non-stick surface of PTFE shovels benefit laboratory work? Enhance Accuracy & Efficiency

- What properties make PTFE/silicone septa suitable for repeated piercing by autosampler needles? | Maximize Sample Integrity

- What are the medical and laboratory equipment uses of PTFE? Unlock Biocompatibility and Chemical Resistance

- What material is used to mold PTFE labware? The Critical Role of Pure PTFE Resin