In the medical and laboratory fields, Polytetrafluoroethylene (PTFE) is a critical material used for everything from life-sustaining implants and surgical instruments to high-purity laboratory containers. Its applications include catheters, surgical sutures, artificial blood vessels, syringe plungers, and protective shielding for radiological equipment. PTFE's unique combination of properties makes it one of the most reliable and versatile polymers for sensitive environments.

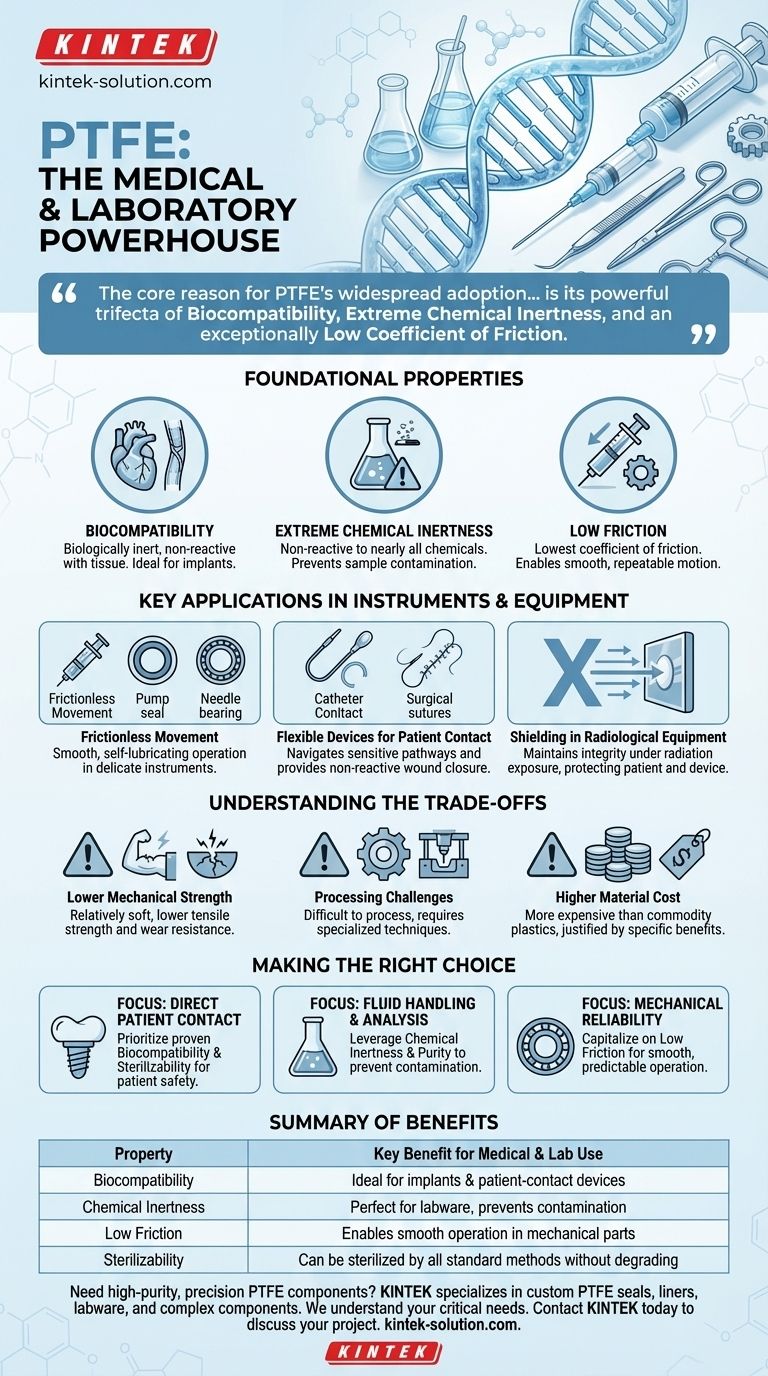

The core reason for PTFE's widespread adoption in medicine and science is not a single feature, but its powerful trifecta of biocompatibility, extreme chemical inertness, and an exceptionally low coefficient of friction. This makes it a uniquely safe and high-performing material where purity and reliability are non-negotiable.

The Foundational Properties of Medical-Grade PTFE

The value of PTFE in clinical and research settings is rooted in its fundamental characteristics. These properties ensure it performs reliably without interfering with biological or chemical processes.

Unmatched Biocompatibility

PTFE is biologically inert, meaning it does not react with human tissue or cause adverse physiological side effects. The body's immune system does not recognize it as a foreign invader.

This makes it an ideal material for implants, such as artificial blood vessels and soft tissue regeneration patches. Expanded PTFE (ePTFE) features a microporous structure that further enhances its use in vascular and cardiac surgery.

Extreme Chemical Inertness

PTFE is non-reactive to nearly all chemicals and solvents. This property is vital in laboratory settings where maintaining the purity of a sample is paramount.

It is used to manufacture containers and pipework for handling highly reactive or corrosive chemicals, ensuring that the material does not leach contaminants into the substance being stored or transported.

Superior Purity and Sterilization

The surface of PTFE naturally resists bacterial growth, contributing to a more hygienic environment. Critically, it can be sterilized by any standard method without degrading its structure or performance.

This makes it a trusted material for reusable instruments and devices like catheters and forceps, where preventing contamination is a primary concern.

Key Applications in Instruments and Equipment

These core properties translate into specific, high-value applications across a range of medical and laboratory devices.

Frictionless Movement in Mechanical Components

PTFE has one of the lowest coefficients of friction of any solid material, making it an ideal self-lubricating surface.

This is leveraged in devices requiring smooth, repeatable motion, such as syringe plungers, pump seals, and needle bearings. This ensures delicate instruments operate without sticking or generating unwanted friction.

Flexible Devices for Patient Contact

The material's flexibility combined with its inertness makes it perfect for devices that come into direct contact with patients.

Catheters made from PTFE can navigate sensitive pathways within the body, while surgical sutures made from PTFE provide a non-reactive means for closing wounds, especially in delicate vascular and general surgeries.

Shielding in Radiological Equipment

PTFE possesses high resistance to radiation, which allows it to maintain its integrity even when exposed to X-rays and other radiological sources.

Because of this, it is used for shielding components and as an insulator in specialized equipment, protecting both the device and the patient.

Understanding the Trade-offs

While PTFE is an exceptional material, it is not the universal solution for every application. A clear-eyed assessment of its limitations is crucial for proper material selection.

Lower Mechanical Strength

Compared to metals or high-strength engineering plastics, PTFE is relatively soft and has lower tensile strength and wear resistance. It is not suitable for high-load structural components where mechanical rigidity is the primary requirement.

Processing Challenges

PTFE can be more difficult to process and machine than more common polymers. Its unique properties require specialized techniques for molding and fabrication, which can influence manufacturing costs and design complexity.

Higher Material Cost

As a high-performance polymer, PTFE is typically more expensive than commodity plastics like polyethylene or polypropylene. Its use is justified in applications where its specific benefits—such as biocompatibility or chemical inertness—are essential.

Making the Right Choice for Your Goal

To apply PTFE effectively, align your material choice with the primary demand of the application.

- If your primary focus is direct patient contact (implants, grafts): Prioritize its proven biocompatibility and ability to be thoroughly sterilized to ensure patient safety.

- If your primary focus is fluid handling and analysis (labware, tubing): Leverage its extreme chemical inertness and purity to prevent sample contamination and material degradation.

- If your primary focus is mechanical reliability (seals, plungers, bearings): Capitalize on its exceptionally low coefficient of friction for smooth, predictable, and non-stick operation in delicate instruments.

Ultimately, PTFE's role in medicine and science is defined by its ability to perform demanding tasks without interfering with the sensitive systems around it.

Summary Table:

| Property | Key Benefit for Medical & Lab Use |

|---|---|

| Biocompatibility | Ideal for implants (e.g., artificial blood vessels) and patient-contact devices; non-reactive with tissue. |

| Chemical Inertness | Perfect for labware and tubing; prevents contamination of sensitive samples. |

| Low Friction | Enables smooth operation in mechanical parts like syringe plungers and seals. |

| Sterilizability | Can be sterilized by all standard methods without degrading, ensuring hygiene. |

Need high-purity, precision PTFE components for your medical or laboratory equipment?

KINTEK specializes in manufacturing custom PTFE seals, liners, labware, and complex components for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical need for biocompatibility, chemical resistance, and reliability in your applications.

From prototypes to high-volume orders, our precision production and custom fabrication ensure your equipment meets the highest standards of performance and safety.

Contact KINTEK today to discuss your project requirements and discover how our PTFE solutions can benefit your designs.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance