The unique performance of PTFE/silicone septa stems from a composite design that pairs the chemical inertness of Polytetrafluoroethylene (PTFE) with the elastic, self-sealing nature of silicone. The PTFE layer provides a clean, non-reactive barrier that faces the sample, while the thicker silicone layer provides the mechanical resilience needed to reseal after being pierced by an autosampler needle. This dual-material strategy is fundamental to maintaining sample integrity during automated analysis.

The septum is not a single material but a strategic laminate. It leverages PTFE for chemical protection and silicone for mechanical resilience, ensuring that repeated punctures do not compromise the sample or the analytical system.

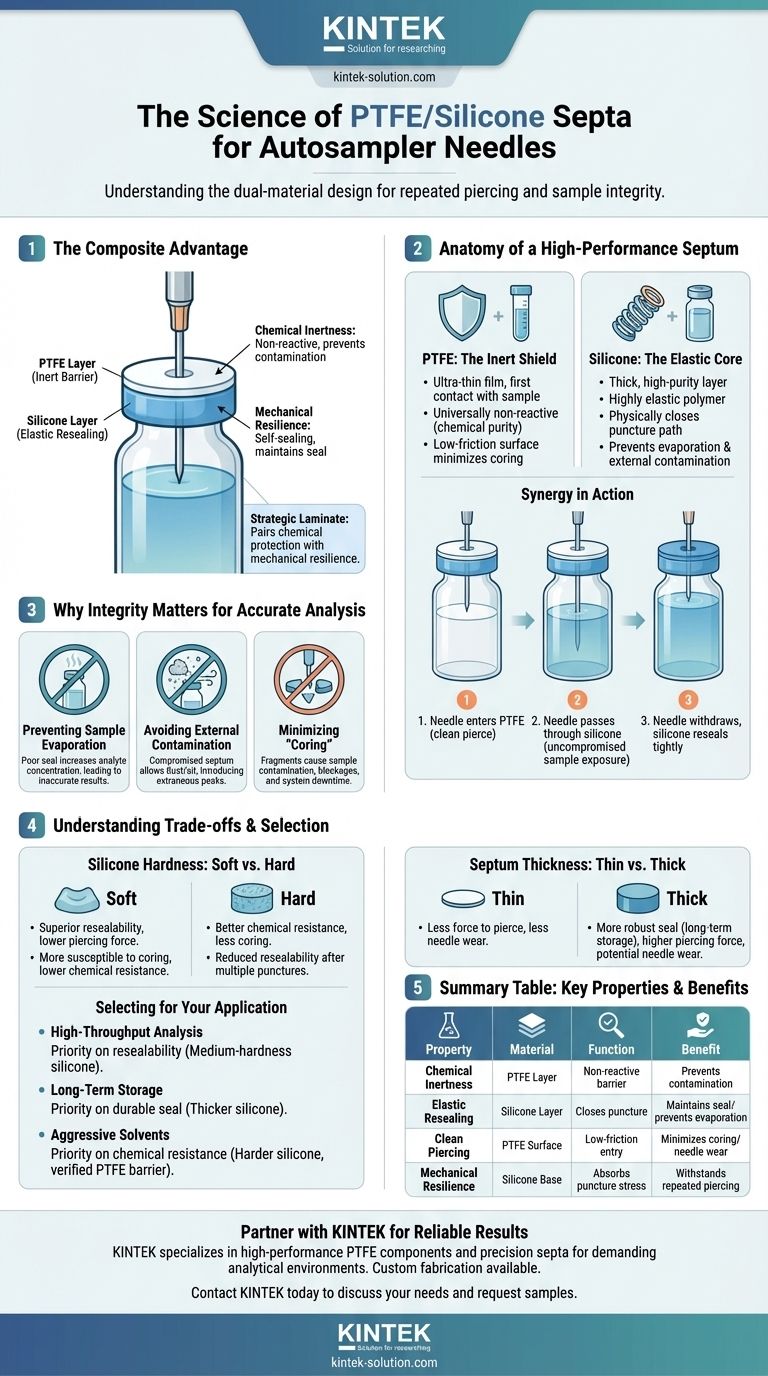

The Anatomy of a High-Performance Septum

To understand why these septa work so well, you must see them not as a single disc but as a two-part system where each material performs a distinct and critical function.

The Role of the PTFE Layer: An Inert Barrier

The ultra-thin PTFE film is the first point of contact for both the sample and the needle. Its primary purpose is to provide chemical inertness.

PTFE is almost universally non-reactive, meaning it will not leach contaminants into your sample or react with your solvent. This ensures the chemical purity of your sample is preserved.

Its low-friction surface also helps the needle pierce cleanly, reducing the likelihood of "coring," where a piece of the septum is torn away.

The Role of the Silicone Layer: Elastic Resealing

Beneath the PTFE film is a much thicker layer of high-purity silicone. This material provides the septum's mechanical elasticity and resealability.

Silicone is a highly elastic polymer. When the autosampler needle is withdrawn, the silicone physically closes the puncture path, maintaining a tight seal.

This resealing action is what prevents solvent evaporation and stops atmospheric contaminants from entering the vial between injections, which is critical in a long analytical sequence.

The Synergy of the Two-Layer System

The design laminates the thin, inert PTFE film onto the thick, elastic silicone base. When the needle enters the vial, it first passes through the clean PTFE and then the resealable silicone.

This ensures the sample is only ever exposed to the non-reactive PTFE, while the silicone does the heavy lifting of maintaining the physical seal.

Why Septum Integrity is Critical for Accurate Analysis

A failing septum directly compromises your results. The entire purpose of the PTFE/silicone design is to mitigate the risks associated with repeated punctures.

Preventing Sample Evaporation

A poor seal allows volatile solvents to evaporate over time. This artificially increases the concentration of your analyte, leading to inaccurate and non-reproducible quantitative results. A well-sealed septum is your first line of defense against this common error.

Avoiding External Contamination

A compromised septum can allow dust, air, or other environmental contaminants to enter the vial. These can introduce extraneous peaks into your chromatogram, react with your sample, or otherwise degrade its integrity.

The Problem of "Coring"

Coring occurs when the needle punches out a small piece of the septum material instead of piercing it cleanly. This fragment can fall into the sample, causing contamination, or worse, become lodged in the autosampler needle or injection valve.

A stuck core fragment can cause blockages, leading to pressure faults, system downtime, and costly repairs. The low-friction PTFE layer is specifically designed to minimize this risk.

Understanding the Trade-offs

Not all PTFE/silicone septa are created equal. The specific grade and thickness of the materials involve trade-offs that affect performance.

Softer vs. Harder Silicone

Softer silicone generally offers superior resealability and requires less force to pierce. However, it may be more susceptible to coring and show lower resistance to aggressive organic solvents.

Harder silicone provides better resistance to harsh chemicals and is less prone to coring. The trade-off is that it may not reseal as effectively after multiple punctures, making it less ideal for high-throughput sequences.

The Impact of Septum Thickness

Thicker septa offer a more robust and reliable seal, providing better protection against evaporation, especially for long-term storage.

The downside is that they require more force to pierce. This can increase wear on the autosampler needle over time, potentially leading to more frequent maintenance.

Selecting the Right Septum for Your Application

Your choice should align directly with your analytical goals, balancing the need for resealability with chemical compatibility and storage time.

- If your primary focus is high-throughput analysis: Prioritize a septum with excellent resealability, often made from a medium-hardness silicone, to handle many injections without sample evaporation.

- If your primary focus is long-term sample storage: Choose a septum with a thicker silicone layer to ensure a durable, long-lasting seal against evaporation and contamination.

- If your primary focus is working with aggressive solvents: Select a septum made from a harder grade of silicone and verify that the PTFE layer provides a complete, chemically inert barrier.

Ultimately, understanding the dual-material construction of your septum empowers you to protect your sample's integrity and ensure the reliability of your results.

Summary Table:

| Property | Material | Function | Benefit |

|---|---|---|---|

| Chemical Inertness | PTFE Layer | Non-reactive barrier facing the sample | Prevents sample contamination and leaching |

| Elastic Resealing | Silicone Layer | Closes puncture path after needle withdrawal | Maintains seal, prevents evaporation and contamination |

| Clean Piercing | PTFE Surface | Low-friction needle entry | Minimizes coring and needle wear |

| Mechanical Resilience | Silicone Base | Absorbs puncture stress | Withstands repeated piercing in automated sequences |

Ensure your analytical results are never compromised by a failing septum.

At KINTEK, we specialize in manufacturing high-performance PTFE components, including precision septa designed for the demanding environments of semiconductor, medical, laboratory, and industrial applications. Our PTFE/silicone septa are engineered for superior chemical resistance and reliable resealing, protecting your samples and your equipment.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact septum specification your process requires.

Contact KINTEK today to discuss your application needs and request samples. Let our expertise in precision PTFE manufacturing enhance the reliability of your automated analysis.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application