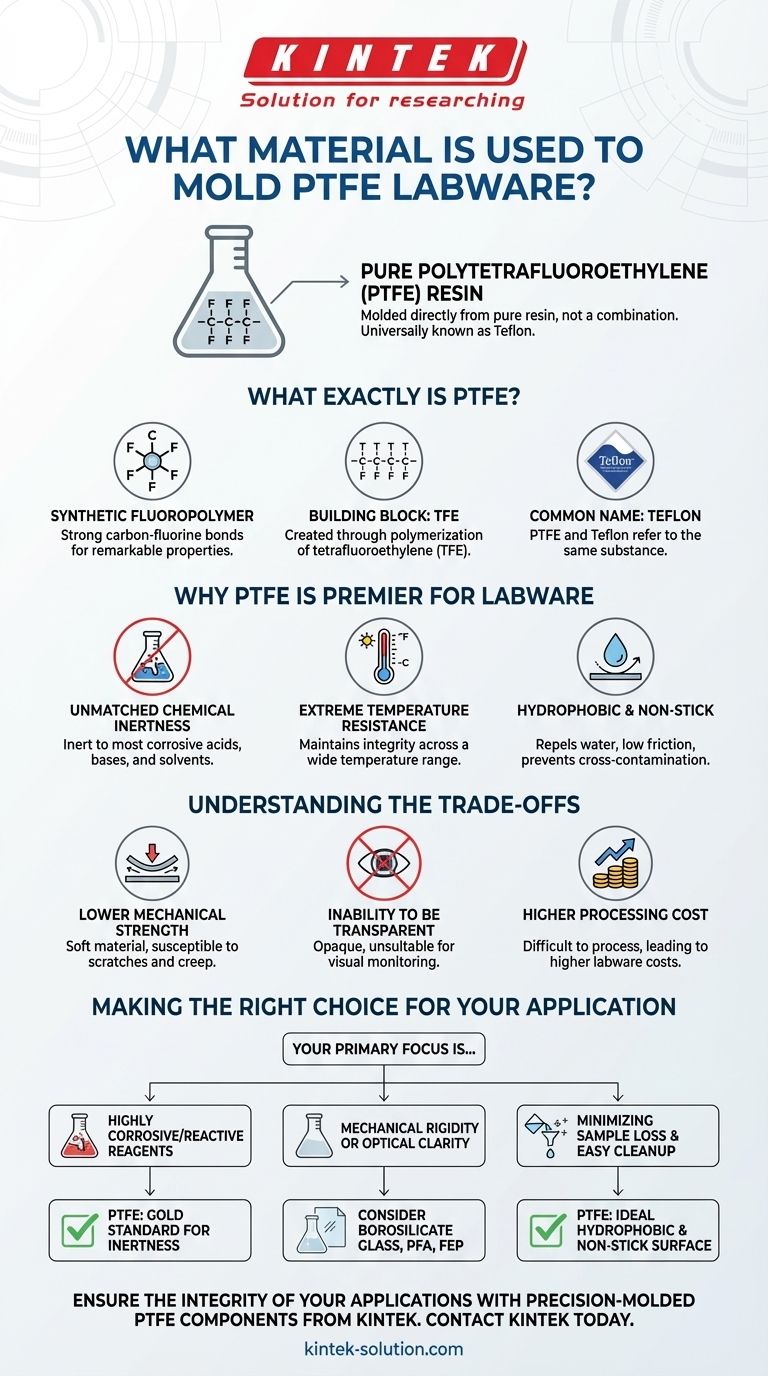

The material used to create this labware is pure polytetrafluoroethylene, a synthetic fluoropolymer thermoplastic almost universally known by its DuPont brand name, Teflon. The labware is molded directly from this PTFE resin, not from a combination of materials. This means the properties of the final product are the inherent properties of PTFE itself.

The critical takeaway is that PTFE labware is molded from pure polytetrafluoroethylene resin. Its unique chemical structure provides the exceptional non-reactivity and resistance to extreme temperatures that make it indispensable for demanding laboratory environments.

What Exactly is Polytetrafluoroethylene (PTFE)?

A Synthetic Fluoropolymer

PTFE is a man-made polymer, specifically a fluoropolymer. This class of materials is defined by exceptionally strong carbon-fluorine bonds, which are the source of its remarkable properties.

The Building Block: TFE

The polymer is created through a process called polymerization. This involves linking together a vast number of tetrafluoroethylene (TFE) molecules into long, stable chains.

The Common Name: Teflon

While its technical name is PTFE, the material is most widely recognized as Teflon. Understanding that PTFE and Teflon refer to the same fundamental substance is key to identifying it in various contexts.

Why PTFE is a Premier Material for Labware

Unmatched Chemical Inertness

The strength of its carbon-fluorine bonds makes PTFE almost completely inert. It will not react with the vast majority of corrosive acids, bases, and solvents used in a laboratory setting, ensuring sample purity.

Extreme Temperature Resistance

PTFE maintains its integrity across a wide functional temperature range. This stability is crucial for experiments that involve heating or cooling, preventing the labware from melting, degrading, or leaching chemicals.

A Hydrophobic & Non-Stick Surface

The material is hydrophobic (repels water) and has an extremely low coefficient of friction. This non-stick quality is vital for preventing cross-contamination between samples and ensures complete transfer of materials.

Understanding the Trade-offs

Lower Mechanical Strength

PTFE is a relatively soft material. It is susceptible to scratches and "creep," a slow deformation that can occur when it's under a constant load. It is not suitable for high-pressure or mechanically stressful applications.

Inability to be Transparent

Unlike glass or other polymers like PFA, PTFE is opaque. This makes it unsuitable for applications where you need to visually monitor a reaction or accurately gauge liquid volumes by sight.

Higher Processing Cost

Due to its high melting point and melt viscosity, PTFE is more difficult to process and mold than common plastics. This complexity contributes to a higher cost for PTFE labware compared to glass or polypropylene alternatives.

Making the Right Choice for Your Application

The choice of labware material directly impacts the reliability of your results.

- If your primary focus is handling highly corrosive or reactive reagents: PTFE is the gold standard due to its unmatched chemical inertness.

- If your primary focus is applications requiring mechanical rigidity or optical clarity: You should consider alternatives like borosilicate glass, PFA, or FEP, as PTFE is soft and opaque.

- If your primary focus is minimizing sample loss and ensuring easy cleanup: PTFE's hydrophobic and non-stick surface makes it an ideal choice.

Understanding the fundamental properties of PTFE allows you to select lab equipment with confidence, ensuring the integrity of your work.

Summary Table:

| Property | PTFE Labware Characteristic |

|---|---|

| Material | Pure Polytetrafluoroethylene (PTFE) Resin |

| Key Benefit | Unmatched chemical inertness and extreme temperature resistance |

| Primary Use | Handling highly corrosive or reactive reagents |

| Limitation | Opaque and lower mechanical strength compared to alternatives |

Ensure the integrity of your most demanding applications with precision-molded PTFE components from KINTEK.

Our expertise in custom fabrication—from prototypes to high-volume orders—guarantees that your PTFE seals, liners, and labware deliver the superior chemical resistance and thermal stability your work requires.

Contact KINTEK today to discuss your specific needs for the semiconductor, medical, laboratory, or industrial sectors.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments