At its core, the non-stick surface of a Polytetrafluoroethylene (PTFE) shovel provides three critical benefits in a laboratory setting: it prevents sample loss from adhesion, drastically simplifies cleaning, and minimizes the risk of cross-contamination between experiments. This unique property directly enhances the accuracy and efficiency of scientific work.

The true value of a PTFE shovel's non-stick surface lies in its ability to protect data integrity. By ensuring complete sample transfer and eliminating a key source of contamination, it safeguards the reliability of your experimental results.

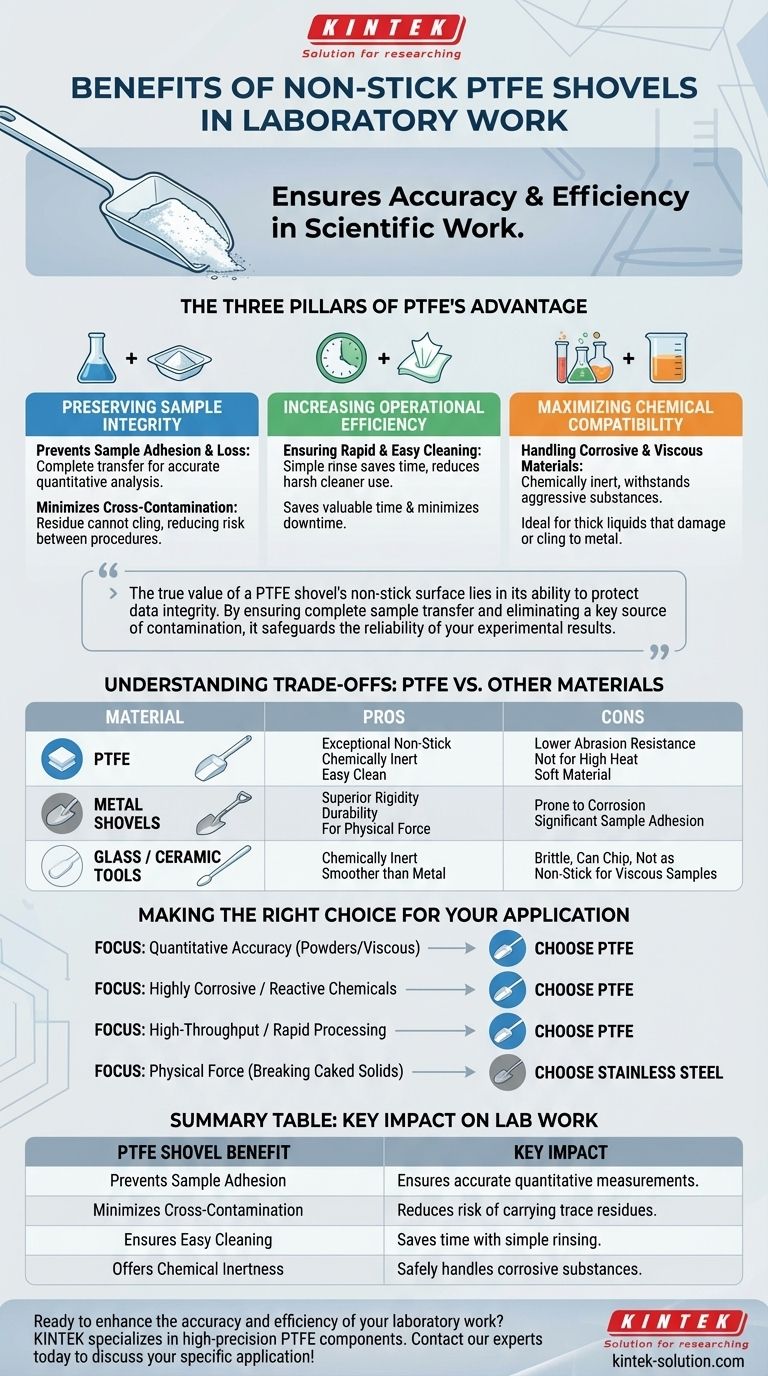

The Three Pillars of PTFE's Advantage

The benefits of a PTFE shovel's surface can be understood through three primary areas of impact: sample integrity, operational efficiency, and chemical compatibility. Each contributes to more reliable and repeatable lab work.

Pillar 1: Preserving Sample Integrity

Preventing Sample Adhesion and Loss When working with fine powders, viscous liquids, or sticky substances, material left behind on a tool can compromise quantitative measurements. The non-stick nature of PTFE ensures the entire sample is transferred from the shovel to its destination, which is critical for accurate analysis.

Minimizing Cross-Contamination A surface that resists adhesion is also a surface that is difficult to contaminate. Because residue from a previous sample cannot easily cling to the PTFE, the risk of carrying trace amounts into your next procedure is significantly reduced.

Pillar 2: Increasing Operational Efficiency

Ensuring Rapid and Easy Cleaning The non-stick surface makes cleaning effortless. A simple rinse or wipe is often sufficient to prepare the shovel for its next use, saving valuable time and reducing the need for harsh cleaning agents that could themselves become contaminants.

Pillar 3: Maximizing Chemical Compatibility

Handling Corrosive and Viscous Materials PTFE is chemically inert, meaning it does not react with most harsh or corrosive chemicals. This property, combined with its non-stick surface, makes it the ideal tool for handling aggressive substances or thick liquids that would damage or cling to metal shovels.

Understanding the Trade-offs: PTFE vs. Other Materials

While highly effective, PTFE is not the universal solution for every lab task. Understanding its limitations compared to other materials is key to selecting the right tool for the job.

vs. Metal Shovels

Metal shovels and spatulas offer superior rigidity and durability. They are better suited for physically demanding tasks like breaking up caked or solidified materials. However, they are prone to corrosion from harsh chemicals and suffer from significant sample adhesion.

vs. Glass or Ceramic Tools

Glass and ceramic tools share PTFE's chemical inertness but are brittle and can easily chip, introducing foreign particulates into a sample. While smoother than metal, they do not match the exceptional non-stick performance of PTFE, especially with viscous samples.

Physical Limitations of PTFE

It's important to recognize that PTFE is a relatively soft material with lower abrasion resistance and temperature tolerance than metal or ceramic. It is not intended for high-heat applications or for scraping hard surfaces.

Making the Right Choice for Your Application

Selecting the proper tool is a foundational step in any successful experiment. Use these guidelines to make an informed decision based on your primary objective.

- If your primary focus is quantitative accuracy with powders or viscous liquids: Choose PTFE to ensure complete and uncontaminated sample transfer.

- If your primary focus is handling highly corrosive or reactive chemicals: Choose PTFE for its superior chemical inertness and resistance to degradation.

- If your primary focus is high-throughput screening or rapid processing: Choose PTFE for its unparalleled ease of cleaning, which minimizes downtime between samples.

- If your primary focus is physical force, such as breaking up caked solids: A stainless steel shovel or spatula is the more appropriate tool.

Ultimately, selecting the right shovel is a deliberate choice that directly supports the reliability and integrity of your laboratory work.

Summary Table:

| PTFE Shovel Benefit | Key Impact on Lab Work |

|---|---|

| Prevents Sample Adhesion | Ensures complete sample transfer for accurate quantitative measurements. |

| Minimizes Cross-Contamination | Reduces risk of carrying trace residues between experiments. |

| Ensures Easy Cleaning | Saves time with simple rinsing, reducing downtime between tasks. |

| Offers Chemical Inertness | Safely handles corrosive or aggressive substances without reaction. |

Ready to enhance the accuracy and efficiency of your laboratory work?

KINTEK specializes in manufacturing high-precision PTFE components, including lab shovels and spatulas, designed to protect your sample integrity. Our custom fabrication services, from prototypes to high-volume orders, ensure you get the perfect tool for your specific application in the semiconductor, medical, laboratory, and industrial sectors.

Contact our experts today to discuss how our PTFE solutions can benefit your workflow!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech