To ensure accurate analysis of polychlorobenzenes, compliant PTFE filters must meet the specifications outlined in NIOSH Method 5517. This standard, which adheres to CDC guidelines, specifically governs the sampling and measurement of these hazardous compounds in occupational settings to protect worker health.

The core requirement is not just about using any PTFE filter, but using one that precisely conforms to the physical and chemical standards of NIOSH Method 5517, ensuring that air sample data is reliable, defensible, and directly comparable for safety assessments.

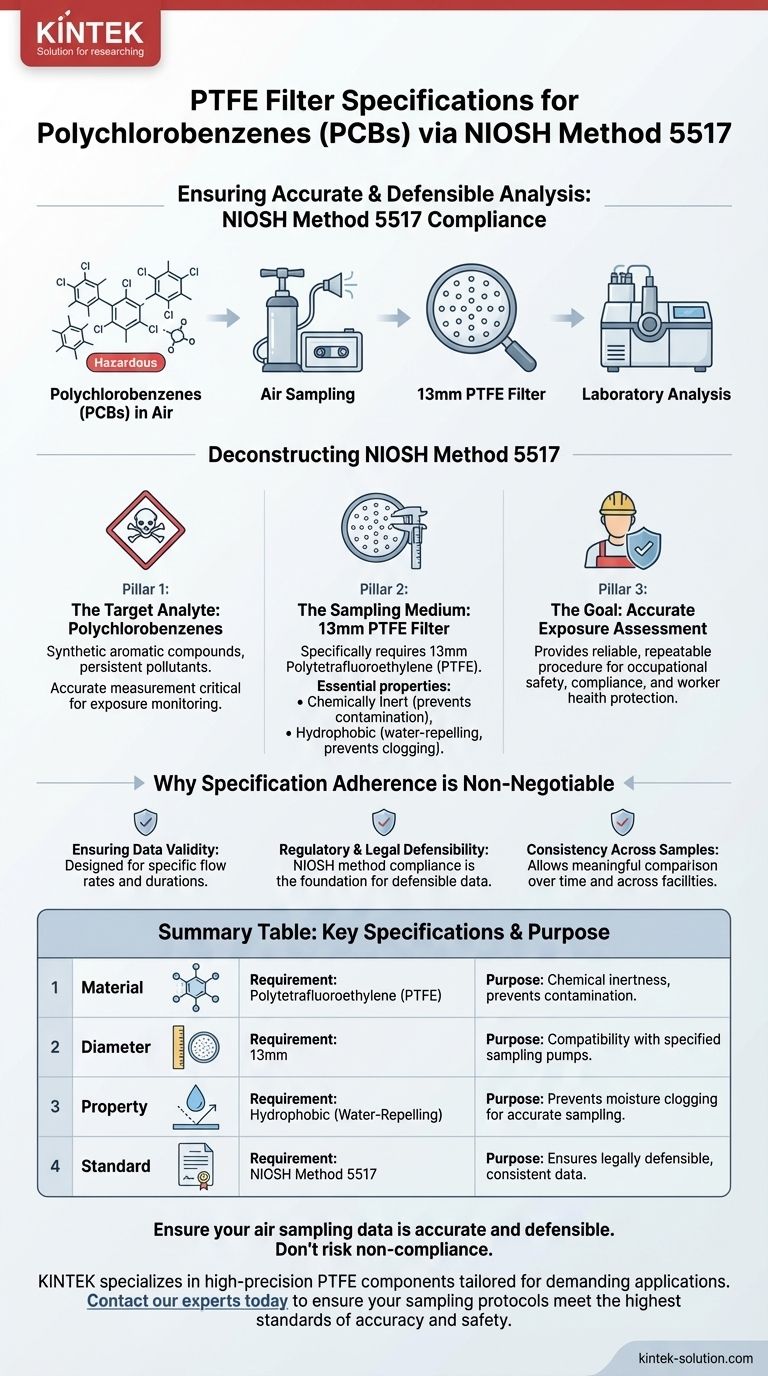

Deconstructing NIOSH Method 5517

NIOSH (The National Institute for Occupational Safety and Health) develops standardized methods to evaluate workplace exposures to chemical and physical hazards. Method 5517 is the specific protocol for Polychlorobenzenes (PCBs).

The Target Analyte: Polychlorobenzenes

Polychlorobenzenes are a group of synthetic aromatic compounds. They are often byproducts of industrial processes and are recognized as persistent environmental pollutants with significant health risks.

Accurate measurement is critical for monitoring exposure and ensuring it remains below permissible limits set by regulatory bodies.

The Sampling Medium: 13mm PTFE Filter

The method explicitly calls for a 13mm Polytetrafluoroethylene (PTFE) filter. This material is not chosen arbitrarily; its properties are essential for the accuracy of the test.

PTFE is chemically inert, meaning it will not react with the polychlorobenzenes or other chemicals in the air sample. This prevents contamination and ensures the captured sample is representative of the actual environment.

Furthermore, PTFE is hydrophobic (water-repelling), which is a crucial advantage in preventing moisture from the air from clogging the filter pores during sampling.

The Goal of the Method: Accurate Exposure Assessment

The ultimate purpose of NIOSH Method 5517 is to provide a reliable, repeatable procedure for industrial hygienists and safety professionals.

Following the method ensures that the collected data is valid for determining worker exposure levels, assessing the effectiveness of control measures, and complying with occupational safety regulations.

Why Specification Adherence is Non-Negotiable

Simply using a "PTFE filter" is insufficient. The filter must meet the exact specifications of the method to guarantee the integrity of your results.

Ensuring Data Validity

The method's parameters, including the 13mm filter diameter and specific pore size, are designed to work with defined air sampling flow rates and durations.

Deviating from these specifications can lead to inaccurate sample collection, either by capturing too little of the analyte or by altering the sample in unintended ways, rendering the results invalid.

Regulatory and Legal Defensibility

In the context of occupational health, analytical results often have legal implications. Adherence to a standardized NIOSH method is the foundation for legally defensible data.

Should exposure levels be questioned or audited, demonstrating strict compliance with Method 5517, including the use of the specified filter, is your primary line of defense.

Consistency Across Samples and Time

Using a standardized filter ensures that results collected by different technicians, at different times, or even at different facilities can be compared meaningfully.

This consistency is vital for long-term exposure trend analysis and for verifying the performance of safety protocols across an organization.

Making the Right Choice for Your Goal

Selecting the correct filter is the first step in a successful and compliant sampling strategy.

- If your primary focus is regulatory compliance: You must source and use 13mm PTFE filters that are explicitly certified or stated to meet the requirements of NIOSH Method 5517.

- If your primary focus is research accuracy: Adhering to the method ensures your results are comparable to established data and are built on a scientifically validated foundation.

Ultimately, strict adherence to the specified filtration media is fundamental to ensuring the safety of personnel and the integrity of your scientific data.

Summary Table:

| Key Specification | Requirement | Purpose |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Chemical inertness to prevent sample contamination. |

| Diameter | 13mm | Compatibility with specified air sampling pumps and flow rates. |

| Property | Hydrophobic (Water-Repelling) | Prevents moisture clogging during sampling for accurate results. |

| Standard | NIOSH Method 5517 | Ensures data is legally defensible and consistent for exposure assessment. |

Ensure your air sampling data is accurate and defensible.

For industrial hygienists and safety professionals, using the correct PTFE filter is the first critical step in complying with NIOSH Method 5517 for polychlorobenzenes. KINTEK specializes in manufacturing high-precision PTFE components, including filters, seals, and labware, tailored for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We understand that your work requires uncompromising quality and adherence to strict specifications. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact components you need for reliable, compliant sampling.

Don't risk non-compliance. Contact our experts today to discuss your specific PTFE filter requirements and ensure your sampling protocols meet the highest standards of accuracy and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance