The primary advantages of PTFE-lined chromatography vials are their exceptional chemical inertness, a non-stick surface that prevents sample loss, and superior sealing capabilities. These core material properties work together to protect the integrity of your sample, directly translating into more accurate, reproducible, and reliable analytical results by preventing contamination, analyte adsorption, and evaporation.

Choosing a vial is not a trivial decision; it is a critical step in ensuring analytical integrity. PTFE-lined vials provide an essential safeguard by creating an inert barrier that protects your sample, preserving the accuracy of your results from the moment of preparation to the point of injection.

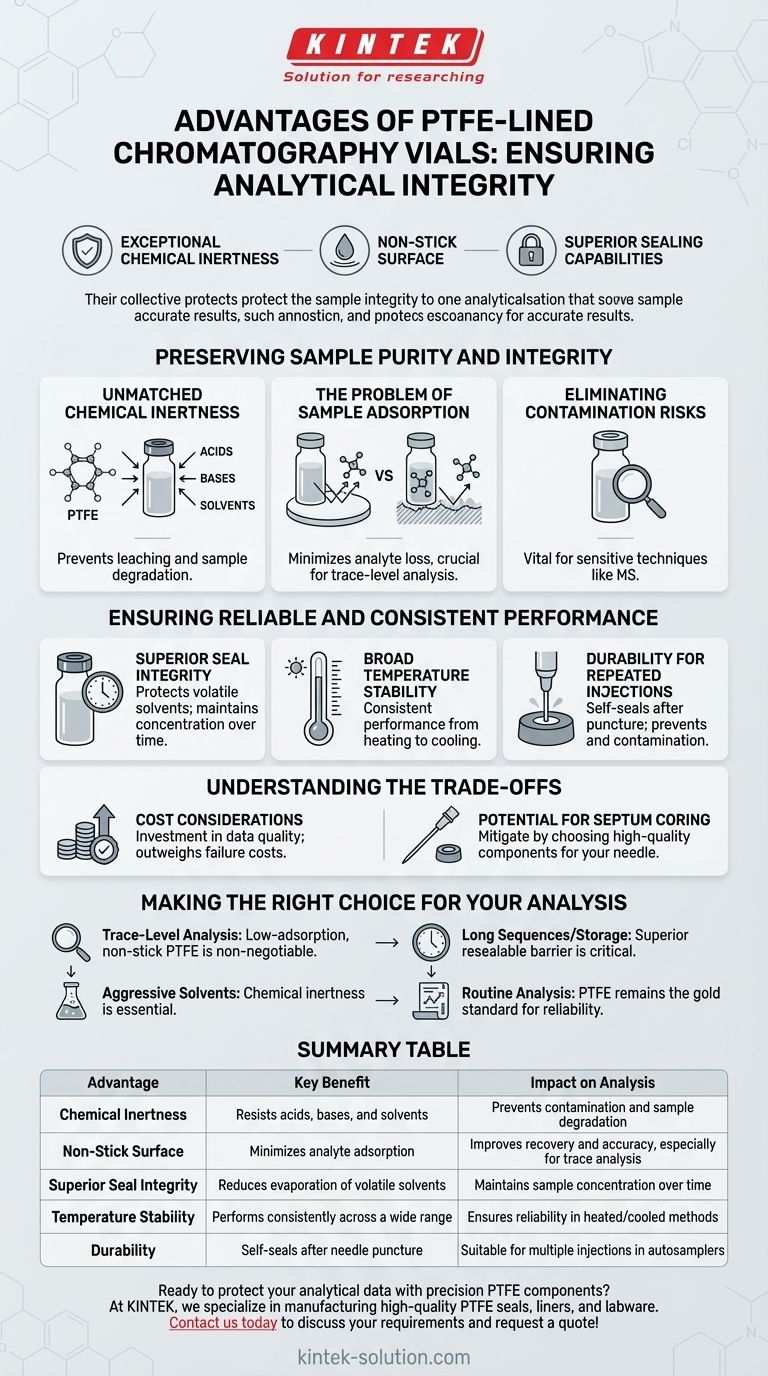

Preserving Sample Purity and Integrity

The most significant benefit of PTFE is its ability to create a completely non-interactive environment for the sample. This ensures that what you analyze is a true representation of your original material, uncompromised by its container.

Unmatched Chemical Inertness

PTFE (Polytetrafluoroethylene) is famously unreactive. It provides a superior barrier against a wide range of chemicals, including aggressive acids, bases, and nearly all organic solvents.

This inertness prevents two critical problems: the leaching of contaminants from the vial or septum into your sample, and the degradation of your sample from reacting with its container.

The Problem of Sample Adsorption

Adsorption occurs when analyte molecules stick to the surface of the container. This is a major source of error, especially in trace-level analysis where even minor losses can dramatically alter results.

PTFE has an extremely low surface energy, creating a non-stick surface. This minimizes the tendency for analytes to adhere to the vial wall or the septum, ensuring maximum sample recovery and improving analytical accuracy.

Eliminating Contamination Risks

The clean, non-reactive surface of PTFE ensures that no foreign materials are introduced into your sample. This is vital for sensitive techniques like mass spectrometry (MS), where even trace levels of contamination can interfere with results.

Ensuring Reliable and Consistent Performance

Beyond chemical compatibility, the physical properties of PTFE ensure that vials perform consistently under demanding laboratory conditions, from the autosampler tray to the injector.

Superior Seal Integrity

A vial's primary job is to contain the sample without loss. PTFE-lined septa create a secure, reliable seal that protects samples from evaporation.

This is critical for volatile solvents and for maintaining accurate sample concentrations over time, especially during long analytical sequences where vials may sit in an autosampler for hours or days.

Broad Temperature Stability

Chromatography often involves heating or cooling samples. PTFE maintains its structural integrity and sealing properties across a wide temperature range, ensuring consistent performance without material degradation.

Durability for Repeated Injections

The septum must withstand being punctured by an autosampler needle without compromising its seal. PTFE-lined septa are designed to be durable and to self-seal effectively after puncture, preventing sample loss and atmospheric contamination on subsequent injections.

Understanding the Trade-offs

While PTFE offers superior performance, it's important to understand its context. No material choice is without practical considerations.

Cost Considerations

Vials and caps featuring PTFE linings are generally more expensive than those with simpler materials like basic rubber or polyethylene.

This higher cost should be viewed as an investment in data quality. The expense of a failed or inaccurate analysis due to vial-related issues far outweighs the marginal savings on a less robust product.

Potential for Septum Coring

Coring occurs when the needle punches out a small piece of the septum, which then falls into the sample. While PTFE is durable, a mismatch between the needle gauge or tip style and the septum can still cause this issue.

Choosing high-quality, well-manufactured vials and septa designed for your specific autosampler needle is key to mitigating this risk.

Making the Right Choice for Your Analysis

Selecting the appropriate vial is a foundational step for generating trustworthy data. Use your analytical goal to guide your decision.

- If your primary focus is trace-level analysis or sensitive compounds: The low-adsorption, non-stick surface of PTFE is non-negotiable for ensuring accurate quantification.

- If your primary focus is working with aggressive solvents or reactive analytes: The chemical inertness of PTFE is essential to prevent sample degradation and contamination.

- If your primary focus is sample integrity during long sequences or storage: The superior, resealable barrier of a PTFE-lined cap is critical to prevent evaporation.

- If your primary focus is routine analysis with stable compounds and mild solvents: While other materials may suffice, PTFE remains the gold standard for guaranteeing reliability and preventing unexpected issues.

Ultimately, selecting PTFE-lined vials is a direct investment in the quality and defensibility of your analytical data.

Summary Table:

| Advantage | Key Benefit | Impact on Analysis |

|---|---|---|

| Chemical Inertness | Resists acids, bases, and solvents | Prevents contamination and sample degradation |

| Non-Stick Surface | Minimizes analyte adsorption | Improves recovery and accuracy, especially for trace analysis |

| Superior Seal Integrity | Reduces evaporation of volatile solvents | Maintains sample concentration over time |

| Temperature Stability | Performs consistently across a wide range | Ensures reliability in heated/cooled methods |

| Durability | Self-seals after needle puncture | Suitable for multiple injections in autosamplers |

Ready to protect your analytical data with precision PTFE components?

At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our components are engineered for unmatched chemical resistance and reliability, ensuring your samples remain pure from preparation to injection.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific application needs. Don't let vial choice compromise your results—invest in precision.

Contact us today to discuss your requirements and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability