In high-performance analytical and medical applications, PTFE-layered septa are used because they provide an exceptionally robust and non-reactive barrier between the sample and the outside environment. This is due to Polytetrafluoroethylene's (PTFE) unique combination of extreme chemical inertness, wide thermal stability, and a non-stick surface, which collectively work to prevent sample contamination and ensure analytical accuracy.

The core challenge in any high-stakes analysis is ensuring that the container does not interfere with the sample. PTFE-layered septa solve this by acting as a nearly perfect shield, guaranteeing that what you measure is your sample, not a contaminant leached from the seal.

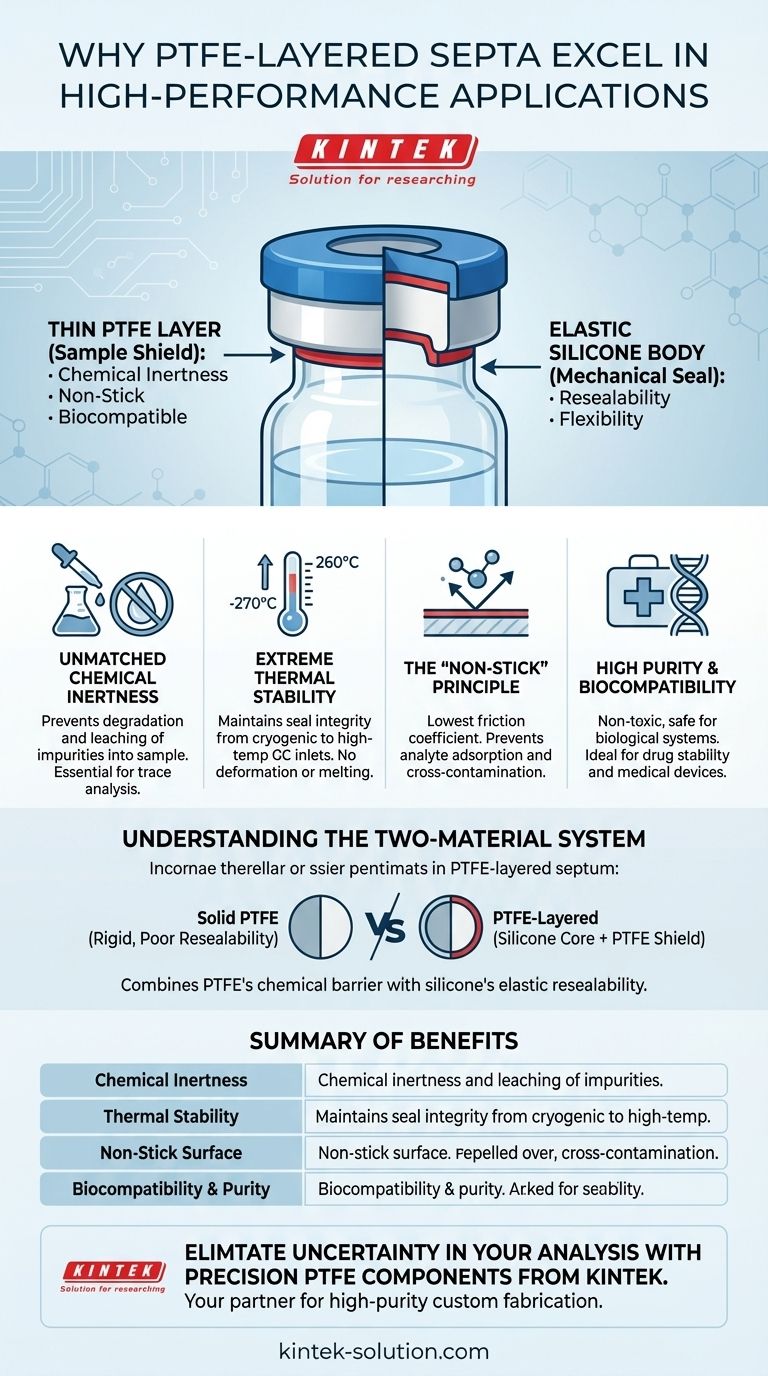

The Core Properties Defining PTFE's Performance

To understand why PTFE is the material of choice, we must look at its fundamental molecular properties. These characteristics directly translate into reliability and precision in demanding environments where other materials would fail.

Unmatched Chemical Inertness

The primary role of a septum is to seal a sample, but it must do so without reacting with it. PTFE is virtually immune to aggressive solvents, strong acids, and bases.

This inertness prevents the septum from degrading and, more importantly, stops it from leaching impurities into the sample. This is non-negotiable in fields like chromatography, where even trace contaminants can invalidate results.

Extreme Thermal Stability

High-performance applications often involve extreme temperatures. PTFE maintains its strength and dimensional stability across an exceptionally wide thermal range, typically from -270°C to 260°C (-454°F to 500°F).

This means the septum will not deform, melt, or become brittle whether used in cryogenic storage or high-temperature gas chromatography (GC) inlets. A stable seal prevents sample loss and protects the integrity of the analysis.

The 'Non-Stick' Principle: Preventing Contamination

PTFE has one of the lowest coefficients of friction of any solid, giving it a famously non-stick or self-lubricating surface.

For a septum, this means that analytes in the sample are far less likely to adsorb (stick) to its surface. This property is critical for preventing cross-contamination between injections and ensuring accurate quantification in trace analysis.

High Purity and Biocompatibility

In medical and pharmaceutical work, the material itself must be fundamentally safe. PTFE is non-toxic and often biocompatible, meaning it does not cause an adverse reaction in biological systems.

This makes it ideal for use in drug stability testing, bioanalysis, and as a sealing material in medical devices, where purity is paramount to patient safety and data validity.

Understanding the Trade-offs: The Two-Material System

A common point of confusion is why these are "PTFE-layered" septa and not made of solid PTFE. The design is a deliberate engineering trade-off that combines the strengths of two different materials.

The Limitation of Solid PTFE

While chemically superior, solid PTFE is a rigid material with poor "memory." If punctured by a needle, it would not reseal effectively, leading to leaks and sample evaporation.

The Function of the Silicone Layer

The bulk of the septum is typically made of silicone. Silicone is highly elastic and provides the excellent resealability required for repeated needle punctures. It is the mechanical workhorse that maintains the physical seal.

The PTFE Layer's Purpose

A very thin layer of PTFE is laminated onto the silicone. This PTFE layer is the only part that faces the sample. It acts as the chemical shield, providing all the benefits of inertness and non-stick properties, while the silicone provides the mechanical flexibility for a reliable seal.

Making the Right Choice for Your Application

The decision to use a PTFE-layered septum is based on the need to eliminate analytical variables and protect sample integrity. Your specific application will determine which of its properties is most critical.

- If your primary focus is trace analysis or chromatography (GC/HPLC): Your main concern is preventing analyte adsorption and carryover, making the PTFE's non-stick surface the most critical feature.

- If your primary focus is working with aggressive chemicals: You need the absolute chemical inertness of the PTFE barrier to prevent sample degradation and septum failure.

- If your primary focus is pharmaceutical or biological samples: The combination of biocompatibility, purity, and inertness is paramount to ensure your results are valid and non-toxic.

- If your primary focus is high- or low-temperature analysis: You depend on PTFE's thermal stability to maintain a secure seal without leaching contaminants into your sample.

Ultimately, choosing PTFE-layered septa is a strategic decision to eliminate uncertainty and ensure the absolute integrity of your results.

Summary Table:

| Property | Benefit for High-Performance Applications |

|---|---|

| Chemical Inertness | Prevents leaching and reaction with aggressive solvents, acids, and bases. |

| Thermal Stability (-270°C to 260°C) | Maintains seal integrity in cryogenic storage and high-temperature GC inlets. |

| Non-Stick Surface | Reduces analyte adsorption and prevents cross-contamination in trace analysis. |

| Biocompatibility & Purity | Essential for pharmaceutical, medical, and biological sample integrity. |

Eliminate uncertainty in your analysis with precision PTFE components from KINTEK.

When your application demands absolute sample integrity—whether in semiconductor manufacturing, medical device sealing, pharmaceutical research, or specialized laboratory analysis—you need a partner who understands the critical role of material science. KINTEK specializes in the custom fabrication of high-purity PTFE components, including seals, liners, and labware.

We prioritize precision production to ensure our parts deliver the chemical resistance, thermal stability, and non-contaminating properties your work depends on. From initial prototypes to high-volume orders, we provide solutions tailored to your exact specifications.

Ready to protect your process and guarantee your results? Contact KINTEK today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is vial type and size compatibility important for PTFE-coated septums? Ensure a Perfect Seal for Reliable Results

- What are the advantages of using PTFE stirrers and shafts in corrosive applications? Ensure Purity and Reliability

- Why are PTFE-coated septums preferred in chromatography? Ensure Sample Integrity and Accurate Results

- Why is consistent performance important in chromatography vials? Ensure Data Integrity and Reproducibility

- What makes PTFE filtration systems advantageous for industrial and scientific use? Unmatched Chemical & Thermal Stability

- Why is the non-wetting property of Teflon coatings important for laboratory glassware? Ensure Experimental Purity & Accuracy

- What customization options are available for PTFE-lined bottle caps? Tailor Caps for Chemical & Temperature Resistance

- How does PTFE enhance the integrity of sealed vials? Ensure Purity and Stability for Your Samples