To enhance the benefits of ring-type gaskets, the ideal material is polytetrafluoroethylene (PTFE). This specific polymer is chosen for its exceptional ability to resist highly corrosive elements and its tolerance for a vast range of operating temperatures, making it a superior choice for demanding industrial applications.

The core reason to use PTFE for ring-type gaskets is to create a robust seal in harsh environments where standard materials would quickly degrade. Its chemical inertness and thermal stability provide a level of reliability that other materials cannot match.

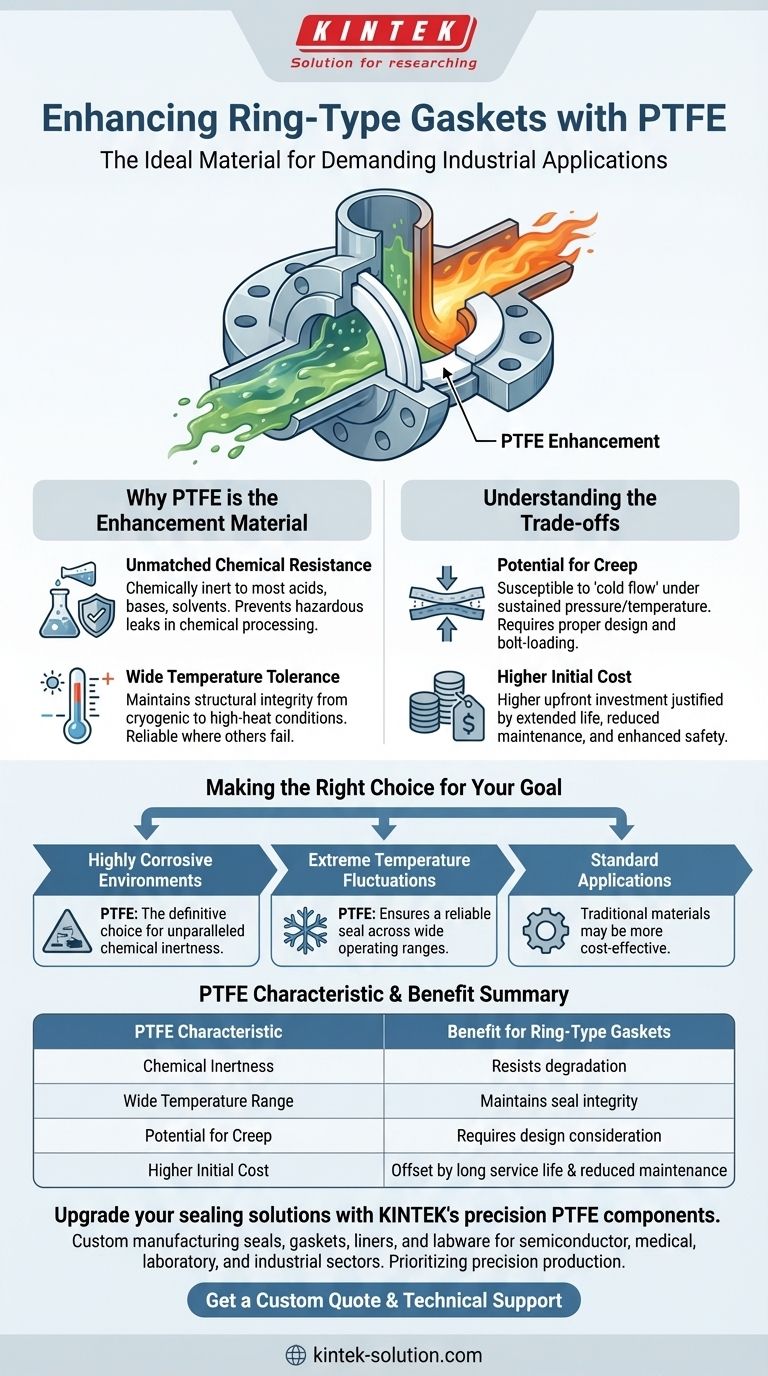

Why PTFE is the Enhancement Material

Standard ring-type gaskets perform well under normal conditions, but their effectiveness diminishes when faced with aggressive chemicals or extreme temperatures. PTFE is not just an alternative; it is a strategic upgrade designed to overcome these specific challenges.

Unmatched Chemical Resistance

PTFE is renowned for being one of the most chemically inert substances known. This means it does not react with most acids, bases, solvents, or other corrosive agents.

This property is critical in industries like chemical processing, where the integrity of a seal is paramount to preventing hazardous leaks.

Wide Temperature Tolerance

The material maintains its structural integrity and sealing capability across an exceptionally broad temperature spectrum.

From cryogenic conditions to high-heat applications, PTFE provides a consistent and reliable seal where other materials might become brittle or fail.

Understanding the Trade-offs

While PTFE offers significant advantages, it is essential to understand its specific characteristics to ensure it is the right choice for your application. No material is a universal solution.

Potential for Creep

Under sustained pressure and temperature, PTFE can be susceptible to "creep" or "cold flow." This is a slow deformation of the material that could potentially compromise the seal over time.

This characteristic must be considered in high-pressure applications, where proper flange design and bolt-loading procedures are critical to mitigate this effect.

Higher Initial Cost

Gaskets manufactured from PTFE typically have a higher upfront cost compared to those made from more common materials.

However, this initial investment is often justified by the gasket's extended service life, reduced maintenance, and enhanced safety in corrosive or high-temperature environments.

Making the Right Choice for Your Goal

Selecting the correct gasket material is a critical engineering decision that directly impacts operational safety and efficiency. Your choice should be dictated by the specific demands of the environment.

- If your primary focus is sealing in highly corrosive environments: PTFE is the definitive choice due to its unparalleled chemical inertness.

- If your application involves extreme temperature fluctuations: PTFE's wide operating range ensures a reliable seal where other materials would degrade.

- If you require a seal for a standard, non-demanding application: A traditional gasket material may be more cost-effective, as the advanced properties of PTFE would be unnecessary.

Ultimately, choosing a PTFE-enhanced gasket is an investment in reliability for your most critical sealing applications.

Summary Table:

| PTFE Characteristic | Benefit for Ring-Type Gaskets |

|---|---|

| Chemical Inertness | Resists acids, bases, and solvents, preventing degradation. |

| Wide Temperature Range | Maintains seal integrity from cryogenic to high-heat conditions. |

| Potential for Creep | Requires consideration in high-pressure applications. |

| Higher Initial Cost | Offset by long service life and reduced maintenance in harsh environments. |

Upgrade your sealing solutions with KINTEK's precision PTFE components.

Our expertise in custom manufacturing PTFE seals, gaskets, liners, and labware ensures a perfect fit for your most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production, offering everything from prototypes to high-volume orders to enhance your operational safety and efficiency.

Contact us today to discuss how our PTFE components can solve your specific sealing challenges.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key features of TFE Encapsulated O-Rings and Gaskets? Achieve Superior Sealing in Demanding Environments

- Why are PTFE seals suitable for high-velocity applications? Superior Performance at Extreme Speeds

- What role do PTFE expansion bellows play in vibration isolation? Protect Piping Systems from Vibration Damage

- What temperature range can PTFE Bellows withstand? Operate from -200°C to +260°C

- What advantages do PTFE spherical balls provide? Unmatched Chemical Resistance & Low Friction

- What are the available forms of PTFE semi-finished products? A Guide to Stock Shapes for Machining

- What types of surface treatments can be applied to PTFE bushes? Enhance Adhesion for Your Assemblies

- How are PTFE Teflon washers used in the automotive industry? Essential for High-Temp, Corrosive Seals