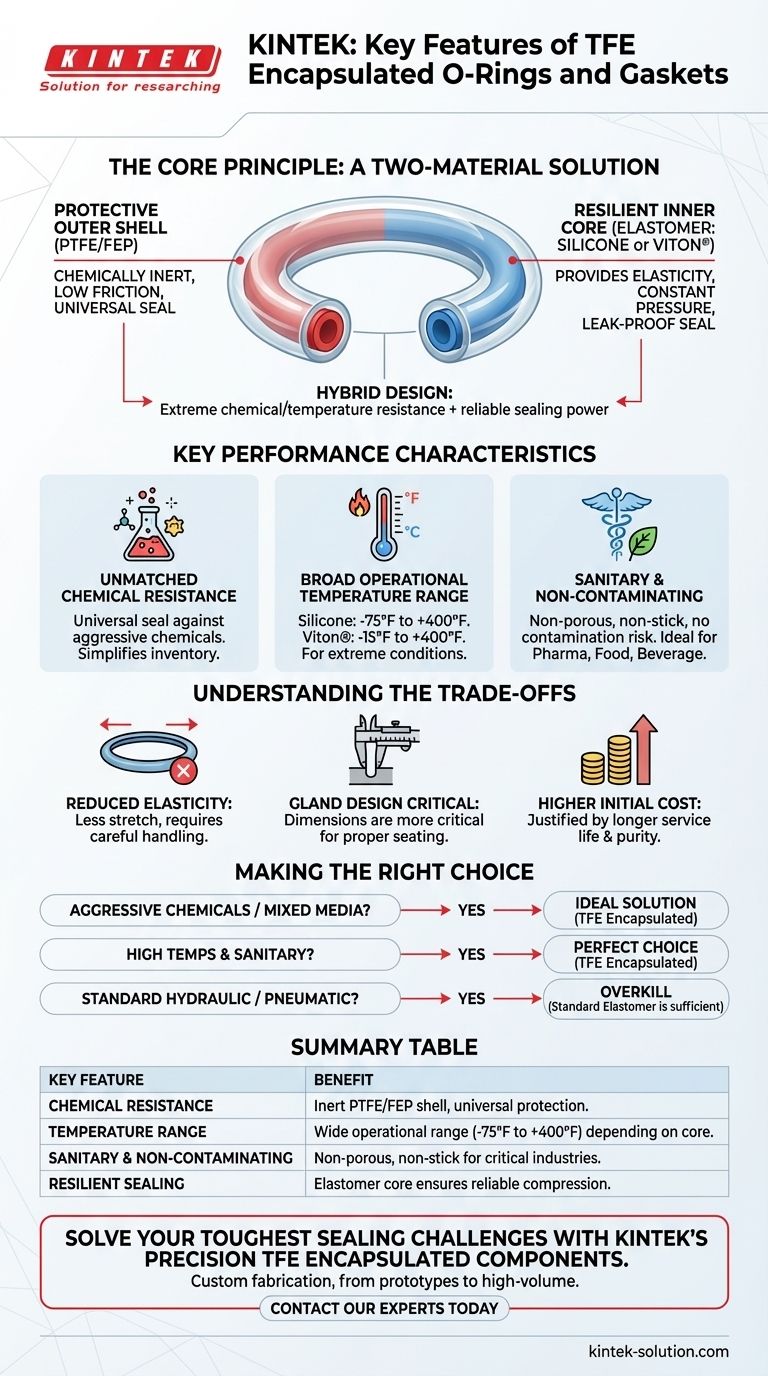

The defining feature of a TFE encapsulated O-ring or gasket is its unique two-part construction, which creates a seal with capabilities that no single material can offer. This hybrid design combines an outer jacket of chemically inert FEP or PTFE (Teflon™) with a flexible, resilient inner core made of an elastomer like silicone or Viton. The result is a seal that provides the exceptional chemical resistance of Teflon™ with the reliable, tight sealing pressure of a standard rubber O-ring.

TFE encapsulated seals merge the extreme chemical and temperature resistance of a rigid fluoropolymer shell with the flexible, reliable sealing power of an elastomeric core. This hybrid design solves critical sealing challenges where a single material would otherwise fail due to chemical attack or poor compression.

The Core Principle: A Two-Material Solution

To understand the value of an encapsulated seal, you must understand how its two components work together to overcome the limitations of each other.

The Protective Outer Shell (PTFE/FEP)

The outer "jacket" is a thin, seamless layer of a fluoropolymer, typically FEP (Fluorinated Ethylene Propylene) or PTFE (Polytetrafluoroethylene).

This material provides the primary defense against the process environment. Its key properties are being chemically inert and having a very low coefficient of friction.

This means the shell does not swell, degrade, or react when exposed to even the most aggressive industrial chemicals and solvents.

The Resilient Inner Core (Elastomer)

A solid PTFE O-ring is rigid and has poor "memory," meaning it doesn't spring back into shape well after being compressed. This makes it a poor choice for dynamic sealing.

The encapsulated design solves this by placing a standard elastomeric O-ring (like Silicone or Viton®) inside the rigid shell. This inner core provides the elasticity and constant pressure needed to maintain a leak-proof seal, even with minor flange imperfections or pressure fluctuations.

Key Performance Characteristics Explained

The two-part design delivers a specific set of high-performance features that make these seals ideal for demanding industrial applications.

Unmatched Chemical Resistance

Because the outer FEP/PTFE shell is inert to nearly all chemicals, it functions as a universal seal. This eliminates the need to stock numerous different elastomer types for various chemical services, simplifying inventory and reducing the risk of incorrect material selection.

Broad Operational Temperature Range

The combination of materials allows for operation in extreme conditions. The specific range depends on the inner core material selected:

- Silicone Core: -75°F to +400°F (-60°C to +205°C)

- Viton® Core: -15°F to +400°F (-26°C to +205°C)

This makes them suitable for processes with significant heat fluctuations, from cryogenic applications to high-temperature processing.

Sanitary and Non-Contaminating

The non-porous, non-stick surface of the outer shell prevents process media from adhering to it. This simplifies cleaning and sterilization procedures.

More importantly, the inert shell poses no risk of contamination, leaching, or imparting taste or odor, making it a superior choice for sanitary applications in the pharmaceutical, food, beverage, and cosmetics industries.

Understanding the Trade-offs

While highly effective, encapsulated seals are not a universal replacement for all standard O-rings. Understanding their limitations is key to using them correctly.

Reduced Elasticity

The rigid outer jacket significantly reduces the stretch and flexibility compared to a bare elastomer O-ring. This requires more careful handling during installation to avoid damaging the jacket.

Gland Design Is More Critical

Because they have less compressibility than a standard O-ring, the dimensions of the groove or gland they are installed in are more critical. A poorly designed gland may prevent the seal from seating correctly or lead to premature failure.

Higher Initial Cost

The complex manufacturing process makes an encapsulated seal more expensive upfront than a standard Viton® or silicone O-ring. However, this cost is often justified by longer service life, reduced downtime, and improved process purity in aggressive environments.

Making the Right Choice for Your Application

Use this guide to determine if an encapsulated seal is the correct solution for your specific goal.

- If your primary focus is handling aggressive chemicals or mixed media: TFE encapsulated seals are the ideal solution, as the inert shell provides universal protection for the energizing core.

- If your application requires both high temperatures and sanitary conditions: The combination of a wide temperature range and a non-contaminating surface makes these seals perfect for pharmaceutical or food processing.

- If your goal is a low-cost seal for a standard hydraulic or pneumatic system: An encapsulated seal is likely overkill; a standard elastomer like Buna-N or Viton® is more forgiving and cost-effective for these applications.

By understanding this hybrid design, you can confidently specify TFE encapsulated seals to ensure reliability and purity in your most demanding applications.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Chemical Resistance | Inert PTFE/FEP shell protects against aggressive chemicals, acts as a universal seal. |

| Temperature Range | Wide operational range (e.g., -75°F to +400°F) depending on inner core material. |

| Sanitary & Non-Contaminating | Non-porous, non-stick surface ideal for pharmaceutical, food, and beverage industries. |

| Resilient Sealing | Elastomer core (Silicone/Viton) provides reliable, leak-proof compression. |

Solve your toughest sealing challenges with KINTEK's precision TFE encapsulated components.

Our hybrid PTFE-encapsulated O-rings and gaskets are engineered for maximum reliability in the semiconductor, medical, laboratory, and industrial sectors. We combine the chemical inertness of PTFE with the resilient sealing of high-performance elastomers to protect your processes from aggressive media and contamination.

KINTEK specializes in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit and superior performance for your specific application.

Contact our experts today to discuss your custom sealing solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability