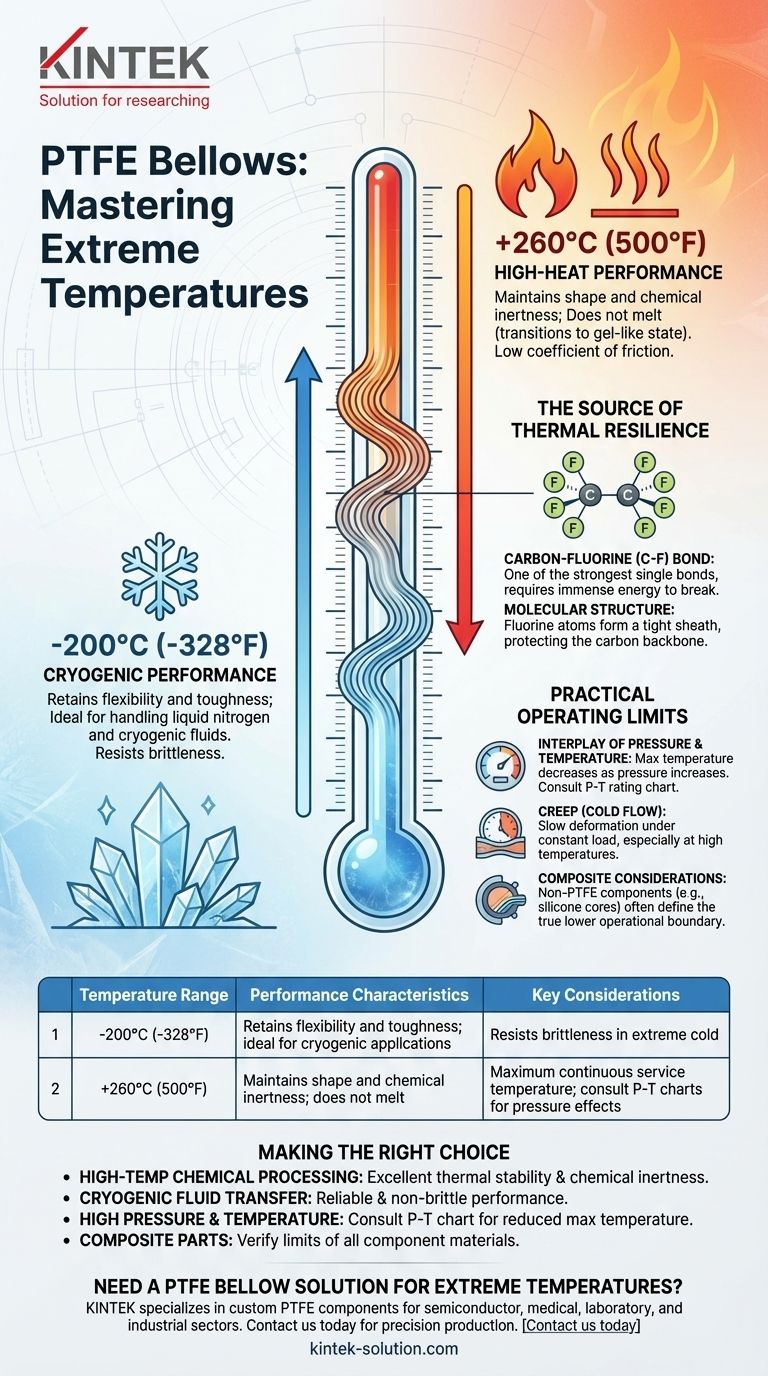

In short, PTFE bellows operate within an exceptionally wide temperature range. They are reliably functional in environments from cryogenic lows of approximately -200°C (-328°F) up to a continuous service temperature of +260°C (500°F). This makes them a premier choice for applications involving severe cold, high heat, or significant thermal cycling.

The true value of PTFE's thermal stability is not just its high upper limit but its exceptional performance across this vast spectrum. It maintains its structural integrity and chemical inertness in conditions where most other plastics and elastomers would fail catastrophically.

The Source of PTFE's Thermal Resilience

Understanding why Polytetrafluoroethylene (PTFE) performs so well requires looking at its unique molecular structure. This is not just a material property; it's a result of fundamental chemistry that gives engineers a predictable and reliable component.

The Carbon-Fluorine Bond

The foundation of PTFE's stability is the carbon-fluorine (C-F) bond, which is one of the strongest single bonds in organic chemistry. This bond requires a tremendous amount of thermal energy to break, giving the material its inherent resistance to heat-induced degradation.

Crystalline and Molecular Structure

The fluorine atoms form a tight, uniform sheath around the carbon backbone of the polymer chain. This structure is incredibly stable and non-reactive, protecting the core of the molecule from chemical attack and thermal stress.

Performance in Extreme Cold (Cryogenics)

While many materials become extremely brittle and fracture at very low temperatures, PTFE retains a useful degree of flexibility and toughness. This makes it a reliable sealing material for cryogenic applications, such as handling liquid nitrogen or other liquefied gases.

Performance in High Heat

At its upper limit of 260°C (500°F), PTFE does not melt but transitions into a gel-like state, maintaining its shape. It exhibits a very low coefficient of friction that remains consistent even at these elevated temperatures, which is critical for dynamic sealing applications.

Understanding the Practical Operating Limits

The headline temperature range is an excellent guide, but in a real-world engineering context, several factors must be considered to ensure reliability and safety.

Continuous vs. Peak Temperature

The standard upper limit of 260°C (500°F) refers to the maximum continuous service temperature. While PTFE can withstand brief, intermittent exposure to slightly higher temperatures, prolonged use above this threshold will lead to accelerated degradation and the release of potentially harmful fumes.

The Interplay of Pressure and Temperature

The maximum allowable operating temperature is directly affected by system pressure. For any bellows or sealing application, you must consult the manufacturer’s specific pressure-temperature (P-T) rating chart. As pressure increases, the maximum safe temperature limit will decrease.

Creep and Cold Flow

PTFE is a relatively soft material and can be subject to creep (also known as "cold flow"), which is a slow, continuous deformation under a constant load. This effect is more pronounced at higher temperatures and must be accounted for in the design of flanges and fittings to prevent leaks over time.

Critical Caveats and Trade-offs

No material is perfect for every situation. Being aware of PTFE's limitations is just as important as knowing its strengths.

Not All "PTFE" is Created Equal

The exceptional temperature range applies specifically to pure, or "virgin," PTFE. Composite parts that use PTFE can have different limitations. For example, a PTFE encapsulated O-ring often has a silicone or Viton™ core. In this case, the core material's lower temperature limit (e.g., 205°C / 400°F) becomes the limiting factor for the entire component.

High Coefficient of Thermal Expansion

PTFE expands and contracts with temperature changes more than metals do. This high coefficient of thermal expansion must be factored into system design, especially where tight tolerances are critical across a wide operational temperature range, to avoid binding or leakage.

Mechanical Strength Decreases with Heat

While thermally stable, the mechanical properties of PTFE, such as its tensile strength and compressive resistance, decrease as it approaches its upper temperature limit. The material becomes softer, which can impact its suitability for high-load-bearing applications at elevated temperatures.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE bellows are the appropriate choice for your specific operational goals.

- If your primary focus is high-temperature chemical processing: PTFE is an excellent choice due to its combined thermal stability and near-universal chemical inertness up to 260°C (500°F).

- If your primary focus is cryogenic fluid transfer: PTFE's ability to remain functional and non-brittle down to -200°C (-328°F) makes it a reliable and proven option.

- If your application involves both high pressure and high temperature: You must consult the manufacturer's pressure-temperature rating chart, as the maximum allowable temperature will be lower than the headline figure.

- If you are considering a composite or filled PTFE part: Always verify the temperature limits of all component materials, as the non-PTFE element often defines the true operational boundary.

By understanding these operational limits and material properties, you can confidently specify PTFE for applications that demand extreme and reliable thermal performance.

Summary Table:

| Temperature Range | Performance Characteristics | Key Considerations |

|---|---|---|

| -200°C (-328°F) | Retains flexibility and toughness; ideal for cryogenic applications | Resists brittleness in extreme cold |

| +260°C (500°F) | Maintains shape and chemical inertness; does not melt | Maximum continuous service temperature; consult P-T charts for pressure effects |

Need a PTFE bellow solution for extreme temperatures?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including bellows, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our precision production ensures reliability across the widest thermal ranges.

Contact us today to discuss your specific application requirements and benefit from our expertise in custom PTFE fabrication.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does Reinforced PTFE differ from Virgin PTFE? Unlock the Right Material for Your Application

- What considerations are important for successful PTFE CNC machining? Master Precision with a Finesse-Over-Force Approach

- In what types of media is the PTFE seat butterfly valve widely used? Essential for Corrosive & High-Purity Applications

- How do PTFE ring gaskets benefit piston engines? Enhance Engine Reliability and Longevity

- Are PTFE slide bearings customizable? Tailor Performance for Your Unique Engineering Challenges

- What are the advantages of machining PTFE over other materials? Unlock Superior Performance in Harsh Environments

- Why are PTFE seats preferred in electric actuated butterfly valves? Enhance Valve Performance and Actuator Lifespan

- What makes expanded PTFE gaskets resistant to corrosion? Unmatched Chemical Inertness for Harsh Environments