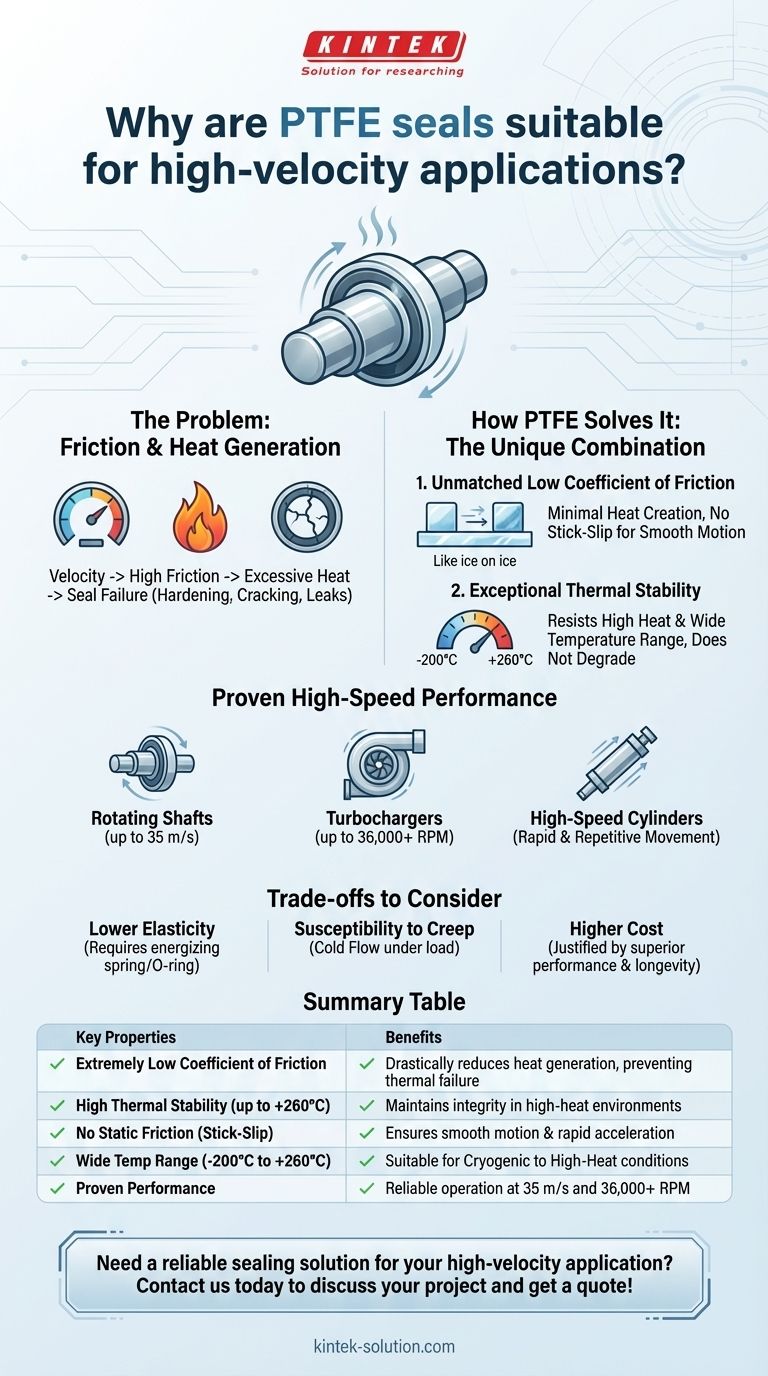

At its core, PTFE is suitable for high-velocity applications because of its unique combination of an extremely low coefficient of friction and high thermal stability. This pairing allows PTFE seals to operate at speeds that would generate destructive levels of heat in traditional elastomeric seals, preventing premature failure and ensuring consistent performance.

The central challenge in high-velocity sealing isn't the speed itself, but the friction-induced heat it creates. PTFE excels because it simultaneously minimizes the creation of heat while also being highly resistant to the heat that is generated.

The Physics of High-Velocity Sealing

To understand why PTFE is a superior choice, we must first examine the fundamental problem that high speeds present to any sealing system. The core issue is the relationship between velocity, friction, and heat.

The Problem: Friction and Heat Generation

In any dynamic sealing application, there is friction between the moving surface (like a shaft or piston) and the stationary seal. As velocity increases, this friction generates a significant amount of heat.

Most common sealing materials, such as standard elastomers (rubber), have a relatively high coefficient of friction. At high speeds, this friction creates a rapid and unsustainable temperature rise directly at the sealing interface.

The Consequence: Seal Failure

This friction-induced heat is the primary cause of seal failure in high-speed applications. Excessive temperatures cause elastomeric materials to harden, crack, or lose their original shape and sealing force.

This degradation leads to leaks, increased friction in a vicious cycle, and ultimately, catastrophic failure of the component and the system it protects.

How PTFE Solves the High-Velocity Challenge

PTFE (Polytetrafluoroethylene) possesses a distinct set of properties that directly counteract the destructive physics of high-speed operation.

Unmatched Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" quality drastically reduces the amount of heat generated, even at very high surface speeds.

Furthermore, PTFE exhibits virtually no static friction, meaning there is no "stick-slip" effect. This ensures smooth, predictable motion and acceleration, which is critical for motion control systems and high-speed cylinders.

Exceptional Thermal Stability

While PTFE's low friction minimizes heat generation, its inherent thermal stability provides a second layer of defense. The material can operate continuously in a very wide temperature range, from cryogenic conditions (~-200°C) up to +260°C.

This means that even when some heat is inevitably generated by friction or high ambient temperatures, the PTFE material does not degrade. It maintains its integrity and sealing properties where elastomers would fail.

Proven Performance at Extreme Speeds

The theoretical benefits of PTFE are proven in demanding real-world applications. PTFE seals are successfully used in:

- Rotating Shafts: Capable of handling surface speeds up to 35 m/s.

- Turbochargers: Lip seals operate reliably at speeds from 4,000 to over 36,000 RPM with limited lubrication.

- High-Speed Cylinders: Providing reliable sealing for rapid and repetitive piston movement.

Understanding the Trade-offs

While exceptional for high-speed applications, PTFE is not a universal solution. Understanding its limitations is key to proper design.

Lower Elasticity

Compared to rubber, PTFE is a much more rigid material. It has poor elastic memory, meaning it does not spring back to its original shape effectively after being compressed.

Because of this, many PTFE seals are "energized" with a separate component, such as a metal spring or an elastomeric O-ring, which provides the constant force needed to maintain a tight seal.

Susceptibility to Creep (Cold Flow)

Under sustained load, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as creep or cold flow, must be accounted for in the hardware design to ensure the seal remains effective over its intended service life.

Higher Material Cost

Engineered PTFE seals are typically more expensive than their standard elastomeric counterparts. The cost is justified by their superior performance, extended service life, and the ability to operate in conditions where other materials simply cannot survive.

Making the Right Choice for Your Application

Selecting the correct seal material requires aligning its properties with the primary demands of your system.

- If your primary focus is extreme rotational speed or rapid acceleration: PTFE is the superior choice. Its low-friction and heat-resistant properties are specifically suited to prevent thermal failure.

- If your primary focus is a low-cost, low-speed static or dynamic seal: A standard elastomeric seal is often the more practical and economical option.

- If you require both high-speed performance and robust sealing at low pressure: An energized PTFE seal is the ideal solution, as it combines PTFE's low friction with the constant sealing force of a spring or O-ring.

Choosing the right material is a critical engineering decision that ensures the performance, reliability, and longevity of your entire system.

Summary Table:

| Key Property | Benefit for High-Velocity Applications |

|---|---|

| Extremely Low Coefficient of Friction | Drastically reduces heat generation, preventing thermal failure |

| High Thermal Stability (up to +260°C) | Maintains integrity in high-temperature environments |

| No Static Friction (Stick-Slip) | Ensures smooth motion and rapid acceleration |

| Wide Temperature Range (-200°C to +260°C) | Suitable for cryogenic to high-heat conditions |

| Proven Performance | Reliable operation at speeds up to 35 m/s and 36,000+ RPM |

Need a reliable sealing solution for your high-velocity application?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware, for demanding industries like semiconductor, medical, and industrial automation. Our expertise ensures your high-speed systems operate reliably and efficiently, preventing costly downtime and failures.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific requirements. Let our team help you select the right PTFE seal design for your application.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the automotive applications of Teflon coating? Boost Performance and Durability

- What is PTFE and what makes it suitable for sealing applications? Solve Extreme Sealing Challenges

- What are the key advantages of using PTFE instrumentation tube fittings? Superior Performance in Extreme Conditions

- What tools and processes are involved in machining PTFE? A Guide to Precision Manufacturing

- How do PTFE extruded rods contribute to electrical insulation? Ensure Uncompromising Performance in Harsh Environments

- What are the advantages of PTFE laminates in PCB applications? Unlock Superior High-Frequency Performance

- How does PTFE impregnated with silicone oil improve gland packing performance? Enhance Sealing with Low Friction

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems