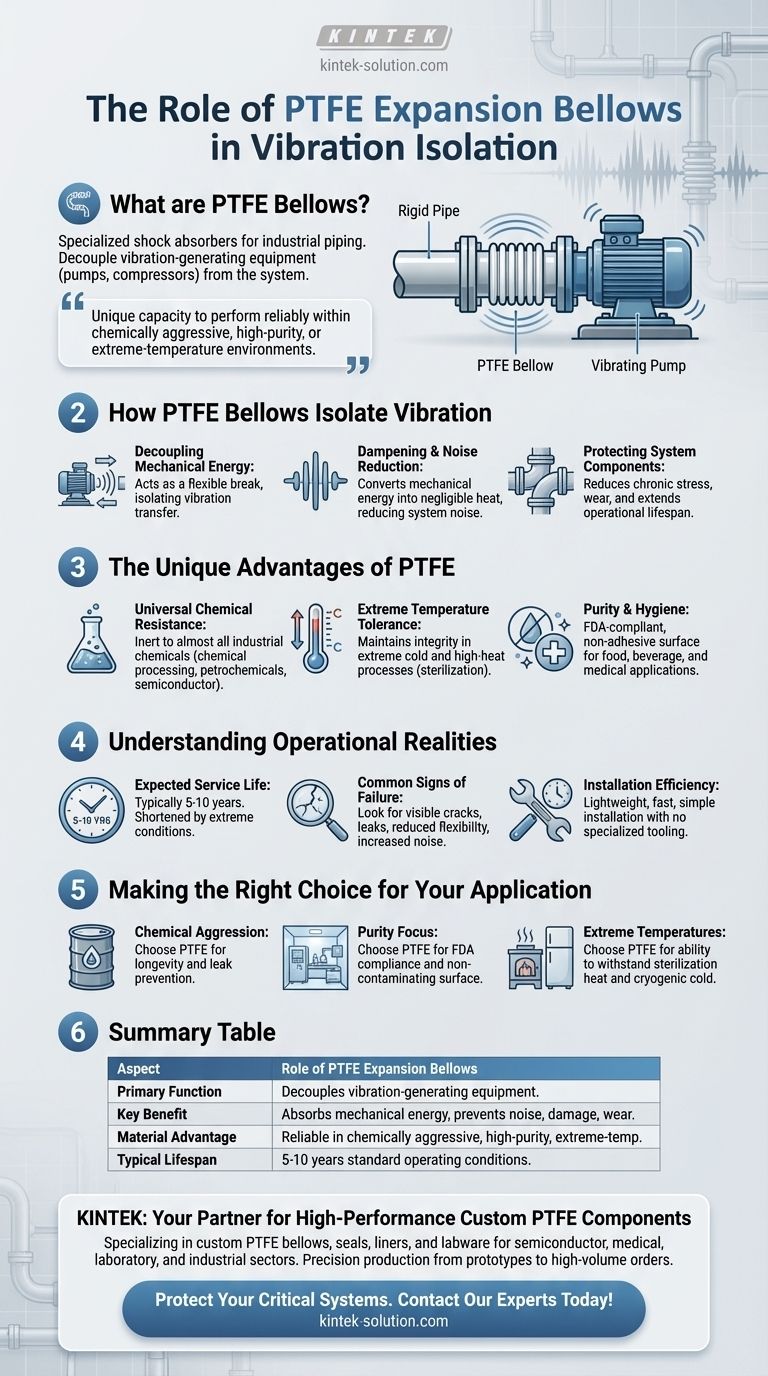

At their core, PTFE expansion bellows function as specialized shock absorbers within industrial piping systems. Their primary role is to decouple vibration-generating equipment, like pumps and compressors, from the rest of the system, absorbing mechanical energy that would otherwise cause noise, damage, and wear.

The true value of a PTFE expansion bellow is not just its ability to dampen vibration, but its unique capacity to perform this function reliably within chemically aggressive, high-purity, or extreme-temperature environments where other materials would quickly fail.

How PTFE Bellows Isolate Vibration

The effectiveness of a PTFE bellow in vibration isolation stems from its fundamental material properties and design. It acts as a flexible break in an otherwise rigid pipeline.

Decoupling Mechanical Energy

A running pump or motor transmits vibrations directly into any connected rigid pipe. A PTFE bellow, with its engineered flexibility, creates a point of absorption that isolates this energy transfer.

This decoupling prevents the vibrations from propagating throughout the entire piping network.

Dampening and Noise Reduction

The flexible structure of the bellow actively dampens mechanical vibrations, converting the energy into negligible heat. This process significantly reduces audible noise generated by the system, a common issue in HVAC and industrial machinery.

Protecting System Components

By absorbing these constant vibrations, PTFE bellows reduce chronic stress and wear on pipe joints, flanges, and connected equipment. This directly contributes to a longer, more reliable operational lifespan for the entire system.

The Unique Advantages of PTFE

While other materials can dampen vibration, PTFE (Polytetrafluoroethylene) is specified for applications where environmental conditions are a critical factor. Its material composition provides a unique combination of benefits.

Universal Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. This makes it the default choice for systems in chemical processing plants, petrochemical pipelines, and semiconductor manufacturing where corrosion would destroy other materials.

Extreme Temperature Tolerance

PTFE bellows maintain their structural integrity and flexibility across a vast temperature range. They are used in applications involving extreme cold as well as high-heat processes, such as high-temperature sterilization in pharmaceutical production.

Purity and Hygiene

The material is FDA-compliant and has non-adhesive properties, meaning substances do not stick to its surface. This is critical in food production, beverage, and medical applications where system purity and ease of cleaning are non-negotiable.

Understanding the Operational Realities

While highly durable, PTFE bellows are not permanent components. Understanding their lifecycle is key to maintaining system integrity.

Expected Service Life

Under typical operating conditions, a PTFE bellow can be expected to last between 5 and 10 years. This lifespan can be significantly shortened by extreme pressures, temperatures, or excessive movement beyond its design limits.

Common Signs of Failure

Regular inspection is critical. Key indicators that a bellow requires replacement include visible cracks, leaks at connection points, a noticeable reduction in flexibility, or an increase in system vibration and noise.

Installation Efficiency

A notable advantage is their lightweight nature, which allows for fast and simple installation. This process typically requires no specialized tooling, reducing labor costs and downtime compared to heavier metal expansion joints.

Making the Right Choice for Your Application

Selecting a PTFE expansion bellow is an engineering decision based on the specific demands of the system.

- If your primary focus is system protection in a chemically aggressive environment: PTFE's unparalleled chemical inertness makes it the most reliable choice to ensure longevity and prevent leaks.

- If your primary focus is maintaining purity in a food, medical, or pharmaceutical process: PTFE's FDA compliance and non-contaminating surface are essential for meeting regulatory standards.

- If your primary focus is vibration control in systems with extreme temperatures: PTFE's ability to withstand sterilization heat and cryogenic cold makes it superior to rubber or other elastomers.

Ultimately, specifying a PTFE bellow is a strategic investment in the stability and longevity of your critical systems.

Summary Table:

| Aspect | Role of PTFE Expansion Bellows |

|---|---|

| Primary Function | Decouples vibration-generating equipment (pumps, compressors) from piping systems. |

| Key Benefit | Absorbs mechanical energy to prevent noise, damage, and wear on components. |

| Material Advantage | Provides reliable performance in chemically aggressive, high-purity, or extreme-temperature environments. |

| Typical Lifespan | 5 to 10 years under standard operating conditions. |

Is vibration, chemical exposure, or extreme temperatures threatening your system's integrity?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including expansion bellows, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a reliable solution tailored to your specific environmental and performance requirements.

Protect your critical systems. Contact our experts today to discuss your application needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments