In short, PTFE-lined caps are critical in professional settings because their chemically inert PTFE (Polytetrafluoroethylene) layer provides a superior, non-reactive barrier. This ensures that the contents of a vial or container remain pure and uncontaminated while also preventing hazardous materials from leaking, making them essential for achieving accurate results and maintaining a safe working environment.

At its core, the challenge in any lab or industrial process is control. When handling sensitive, volatile, or highly pure substances, the cap liner is a primary point of failure. PTFE-lined caps solve this by offering the highest level of chemical inertness and sealing integrity, effectively isolating the sample from its environment and the container itself.

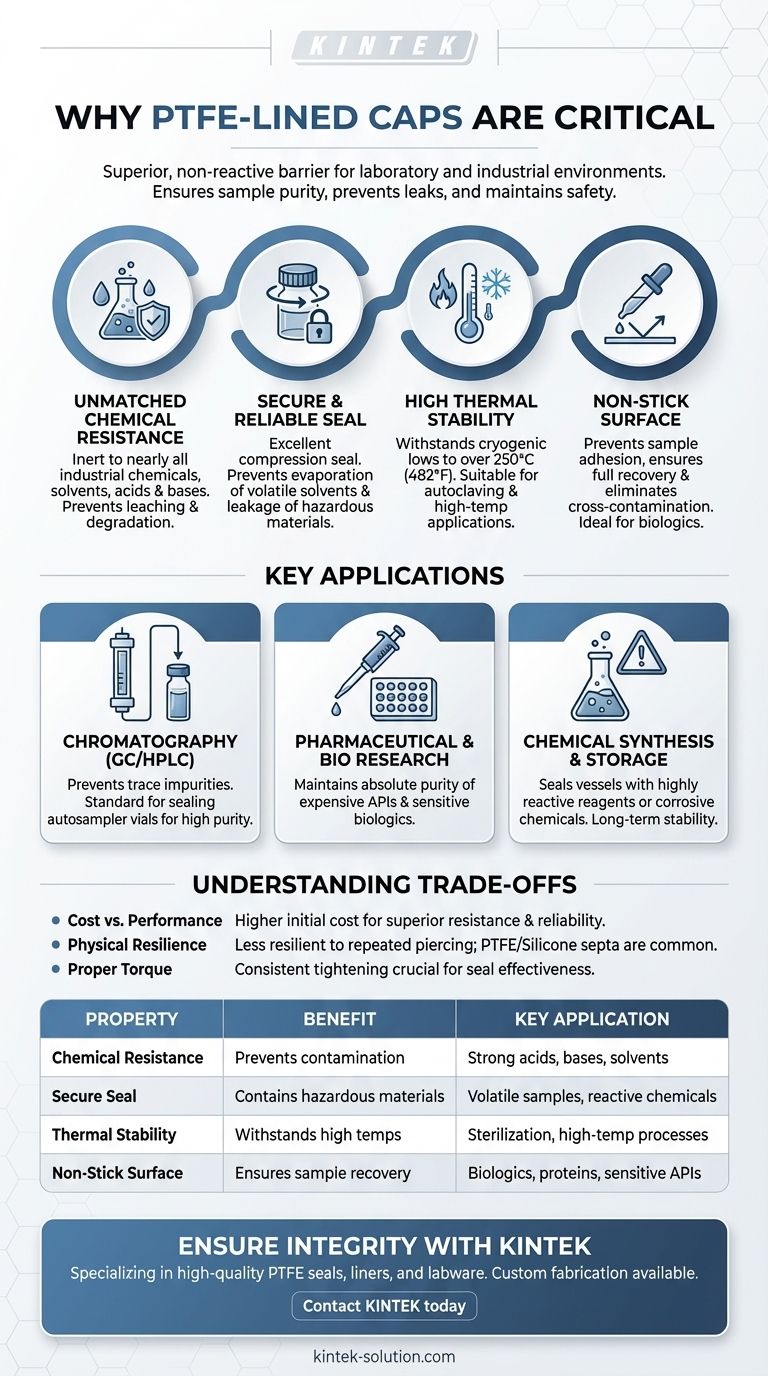

The Core Properties of a PTFE Liner

The effectiveness of PTFE-lined caps stems from the unique molecular structure of Polytetrafluoroethylene. This material delivers a combination of properties that are difficult to achieve with other polymers.

Unmatched Chemical Resistance

PTFE is almost universally inert. It does not react with nearly all industrial chemicals, solvents, acids, and bases.

This property is crucial because it prevents the liner itself from leaching chemicals into the sample, which would compromise analytical results or the purity of a synthesized compound. It also protects the liner from being degraded by corrosive contents.

Creating a Secure and Reliable Seal

A PTFE liner provides an excellent compression seal against the rim of a vial or bottle. This physical barrier is vital for two reasons.

First, it prevents volatile solvents from evaporating and changing the concentration of a sample. Second, it stops hazardous or corrosive materials from leaking, ensuring the safety of personnel and the surrounding environment. This same principle is why PTFE is trusted for sealing industrial valves in high-stakes applications.

High Thermal Stability

PTFE can withstand a wide range of temperatures, from cryogenic lows to highs exceeding 250°C (482°F).

This allows PTFE-lined caps to be used in high-temperature applications where other materials would melt or degrade. It also means they can often be autoclaved for sterilization without losing their sealing integrity.

A Non-Stick Surface for Purity

The famous non-stick quality of PTFE (best known by the brand name Teflon) is also a major advantage in laboratory settings.

This property prevents sample components, especially biologics or proteins, from adhering to the liner. This ensures that the full sample can be recovered and that no cross-contamination occurs between different samples using the same cap type.

Key Applications Where PTFE Liners Excel

The unique properties of PTFE make it the default choice in several demanding fields where sample integrity and safety are non-negotiable.

Chromatography (GC/HPLC)

In analytical techniques like gas or liquid chromatography, even trace levels of contamination can ruin an analysis. PTFE-lined caps are standard for sealing autosampler vials to ensure that no impurities leach from the cap into the highly pure solvents or the sample itself.

Pharmaceutical and Biological Research

When working with expensive Active Pharmaceutical Ingredients (APIs), sensitive biologics, or cell cultures, maintaining absolute purity is paramount. PTFE liners provide an inert barrier that will not interact with or degrade these valuable and delicate materials during storage or experimentation.

Chemical Synthesis and Storage

Chemists rely on PTFE-lined caps to seal vessels containing highly reactive reagents, corrosive chemicals, or air-sensitive compounds. The liner ensures the long-term stability of the stored substance and prevents dangerous reactions or leaks.

Understanding the Trade-offs

While PTFE offers superior performance, it is important to understand its context and limitations to make an informed decision.

Cost vs. Performance

PTFE-lined caps are typically more expensive than those with simpler liners made of polyethylene or rubber. This cost is a direct trade-off for its superior chemical resistance and reliability. For less demanding applications, a cheaper alternative may suffice.

Physical Resilience

While chemically robust, pure PTFE can be less resilient to repeated piercing with a syringe needle compared to silicone. For this reason, many chromatography caps use a PTFE/Silicone septa, which combines the chemical inertness of a thin PTFE layer with the superior resealing capability of a thicker silicone layer.

Importance of Proper Torque

The effectiveness of any cap liner depends on applying the correct torque. Over-tightening can deform the liner and compromise the seal, while under-tightening will fail to create a secure barrier. Consistent, proper technique is key to leveraging the liner's benefits.

Making the Right Choice for Your Application

Ultimately, your choice of cap liner should be dictated by the demands of your specific task.

- If your primary focus is analytical purity (e.g., chromatography, trace analysis): A PTFE-faced liner is non-negotiable to prevent chemical leaching and ensure the accuracy of your results.

- If your primary focus is safety with hazardous materials (e.g., strong acids, reactive chemicals): The inertness and secure seal of a PTFE liner provide the most reliable containment.

- If your primary focus is general storage of non-reactive aqueous solutions: A simpler, less expensive liner may be sufficient, but PTFE still offers the highest level of security and peace of mind.

Choosing a PTFE-lined cap is an investment in the integrity of your sample, the accuracy of your data, and the safety of your process.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Unmatched Chemical Resistance | Prevents contamination and degradation | Handling strong acids, bases, and solvents |

| Secure, Reliable Seal | Contains hazardous materials, prevents evaporation | Sealing volatile samples and reactive chemicals |

| High Thermal Stability | Withstands autoclaving and high temperatures | Sterilization and high-temperature processes |

| Non-Stick Surface | Ensures complete sample recovery, prevents sticking | Working with biologics, proteins, and sensitive APIs |

Ensure the integrity of your samples and the safety of your lab with precision PTFE components from KINTEK.

Whether you are working in the semiconductor, medical, laboratory, or industrial sector, the chemical inertness and reliability of our PTFE components are critical for your success. KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware, offering both standard and custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and let our expertise in precision production enhance your processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do PTFE/silicone septums help reduce sample contamination in chromatography? A Dual-Layer Defense for Your Samples

- What are the key properties of PTFE that make it suitable for labware applications? Ensure Lab Integrity with Superior Material

- What other PTFE lab accessories are commonly used? Essential Tools for Chemical Resistance & Purity

- How does the PTFE bottle perform in terms of chemical resistance? Unmatched Protection for Harsh Chemicals

- What are the advantages of PTFE impellers in terms of chemical resistance? Unmatched Inertness for Demanding Applications

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What makes PTFE filtration systems advantageous for industrial and scientific use? Unmatched Chemical & Thermal Stability

- What are common industrial applications of PTFE filters? Master Critical Filtration in Demanding Industries