Beyond the standard beakers and tubing, a range of specialized PTFE lab accessories are indispensable for specific tasks. These commonly include chemically resistant bottle pourers for hazardous materials, non-contaminating watch glass covers, precision dropping bottles, and magnetic stirring bar retrievers. Each item leverages PTFE's unique properties to solve a distinct challenge in the modern laboratory.

The use of Polytetrafluoroethylene (PTFE) for lab accessories is not a matter of convenience; it is a strategic choice driven by the material's unparalleled chemical inertness and non-stick surface, which are critical for ensuring experimental purity and operational safety.

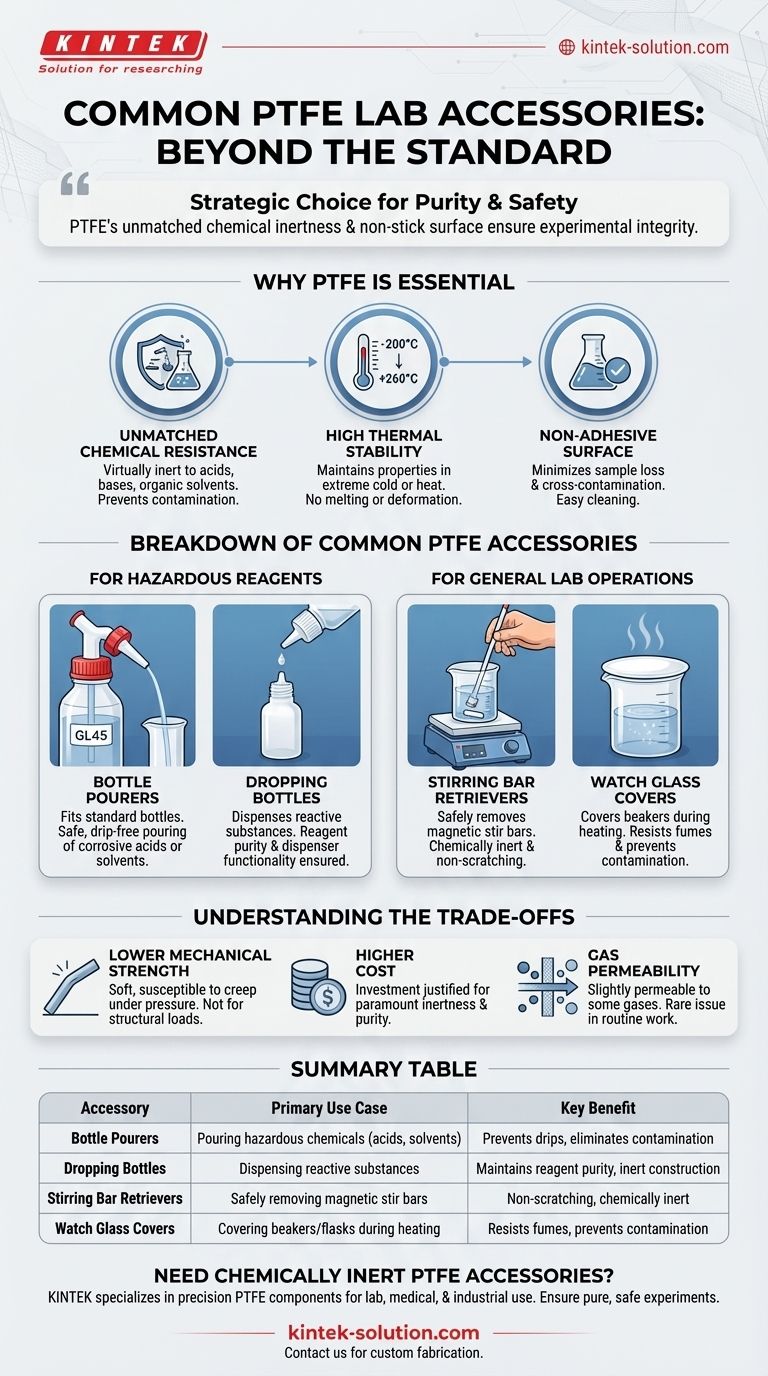

Why PTFE is Essential for Lab Accessories

Before examining specific items, it's crucial to understand why PTFE is the material of choice. Its value comes from a combination of three core properties that are difficult to find in any other single material.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all chemicals, including aggressive acids, bases, and organic solvents. This means the accessory will not degrade, corrode, or leach impurities into your sample, preserving the integrity of your work.

High Thermal Stability

PTFE maintains its properties across a wide temperature range (typically -200°C to +260°C). This makes it suitable for applications involving both cryogenic materials and heated solutions without melting, deforming, or breaking down.

Non-Adhesive Surface

Famously known for its non-stick properties, PTFE's surface resists adhesion. This is critical in a lab setting, as it minimizes sample loss, prevents cross-contamination between experiments, and makes cleaning exceptionally easy and effective.

A Breakdown of Common PTFE Accessories

These core properties make PTFE the ideal material for accessories that directly contact sensitive or aggressive reagents, where contamination or reaction is not an option.

For Handling Hazardous Reagents

Hazardous Chemical Bottle Pourers are designed to fit standard laboratory bottles (with common thread sizes like GL38 and GL45). Their all-PTFE construction allows for the safe and clean pouring of highly corrosive acids or pure solvents directly from the reagent bottle, eliminating drips and preventing any reaction with the pourer itself.

Dropping Bottles made from PTFE provide a solution for dispensing controlled amounts of reactive substances. Unlike glass or standard plastic, a PTFE bottle and dropper cap will not be attacked by the contents, ensuring the reagent remains pure and the dispenser remains functional over time.

For General Lab Operations

A Stirring Bar Retriever is a simple but essential tool for safely removing a magnetic stir bar from a solution. The long PTFE rod encasing a powerful magnet is completely inert, so it won't react with the mixture or scratch the interior of glass vessels.

Watch Glass Covers made from PTFE offer a chemically resistant alternative to glass. They are used to cover beakers or flasks during heating to prevent contamination from dust or condensation while remaining impervious to any fumes or splashes from the solution inside.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the solution for every lab scenario. Being aware of its limitations is key to using it effectively.

Lower Mechanical Strength

PTFE is a relatively soft material. It is not suitable for high-load or high-pressure structural applications where mechanical rigidity is required. It can be susceptible to "creep," or slow deformation under sustained pressure.

Higher Cost

PTFE accessories are significantly more expensive than their counterparts made from glass, polypropylene, or other common plastics. Their cost is an investment that is justified only when chemical inertness and purity are paramount.

Gas Permeability

While excellent at containing liquids, PTFE is slightly permeable to certain small gas molecules. This is rarely an issue in routine lab work but could be a factor in highly sensitive, long-term experiments involving specific gases under pressure.

Making the Right Choice for Your Goal

Selecting the right lab accessory requires matching the material's properties to the demands of your specific task.

- If your primary focus is safely handling aggressive chemicals: Prioritize PTFE bottle pourers and dropping bottles to guarantee reagent purity and prevent equipment degradation.

- If your primary focus is preventing sample contamination: Use PTFE stirring bar retrievers and watch glass covers to maintain a completely inert environment for your reaction or solution.

- If you are working with non-reactive aqueous solutions on a budget: Standard glass or polypropylene accessories are often sufficient, and the premium cost of PTFE is likely unnecessary.

Ultimately, choosing a PTFE accessory is a deliberate investment in the accuracy of your results and the safety of your lab environment.

Summary Table:

| PTFE Accessory | Primary Use Case | Key Benefit |

|---|---|---|

| Bottle Pourers | Pouring hazardous chemicals (acids, solvents) | Prevents drips, eliminates contamination |

| Dropping Bottles | Dispensing reactive substances | Maintains reagent purity, inert construction |

| Stirring Bar Retrievers | Safely removing magnetic stir bars | Non-scratching, chemically inert |

| Watch Glass Covers | Covering beakers/flasks during heating | Resists fumes, prevents contamination |

Need chemically inert PTFE accessories for your lab? KINTEK specializes in precision PTFE components (seals, liners, labware, and custom accessories) for semiconductor, medical, laboratory, and industrial applications. Our expertise ensures your experiments remain pure and safe. Contact us today to discuss custom fabrication from prototypes to high-volume orders!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What role does precision play in the use of PTFE silicone septa for pharmaceutical analysis? Ensure Reliable, Compliant Data

- What are the size options for PTFE-lined bottle caps? Find the Perfect Fit for Your Lab

- What is PTFE and how is it used in vial caps? Ensure Sample Purity with Inert Liner Technology

- What are the key properties of Teflon membranes? Ensure Chemical Resistance and Sample Purity

- How do PTFE/silicone septa reduce sample carryover in HPLC analysis? Achieve Accurate, Contamination-Free Results

- What are PTFE ferromagnetic support discs composed of? A Dual-Material Design for Superior Grinding & Polishing

- What role do sealing properties play in the effectiveness of PTFE/silicone septums? Ensure Sample Integrity and Data Accuracy

- How do stainless steel impellers perform in corrosive environments? Weighing Strength Against Chemical Risk