When sample integrity is paramount, Polytetrafluoroethylene (PTFE) is the material of choice for vial cap liners. PTFE is a highly non-reactive synthetic fluoropolymer, renowned for its "non-stick" and chemically inert properties. In a vial cap, a thin layer of PTFE is bonded to a more pliable material like silicone, creating a septum that acts as an impermeable barrier between the sample and the rest of the cap assembly. This ensures the contents of the vial remain pure and unaltered.

The crucial role of PTFE in a vial cap is not to provide the physical seal, but to serve as an inert chemical shield. This thin liner is what prevents reactive samples from being contaminated by the cap or absorbed into the sealing material, making it the gold standard for analytical science and high-purity storage.

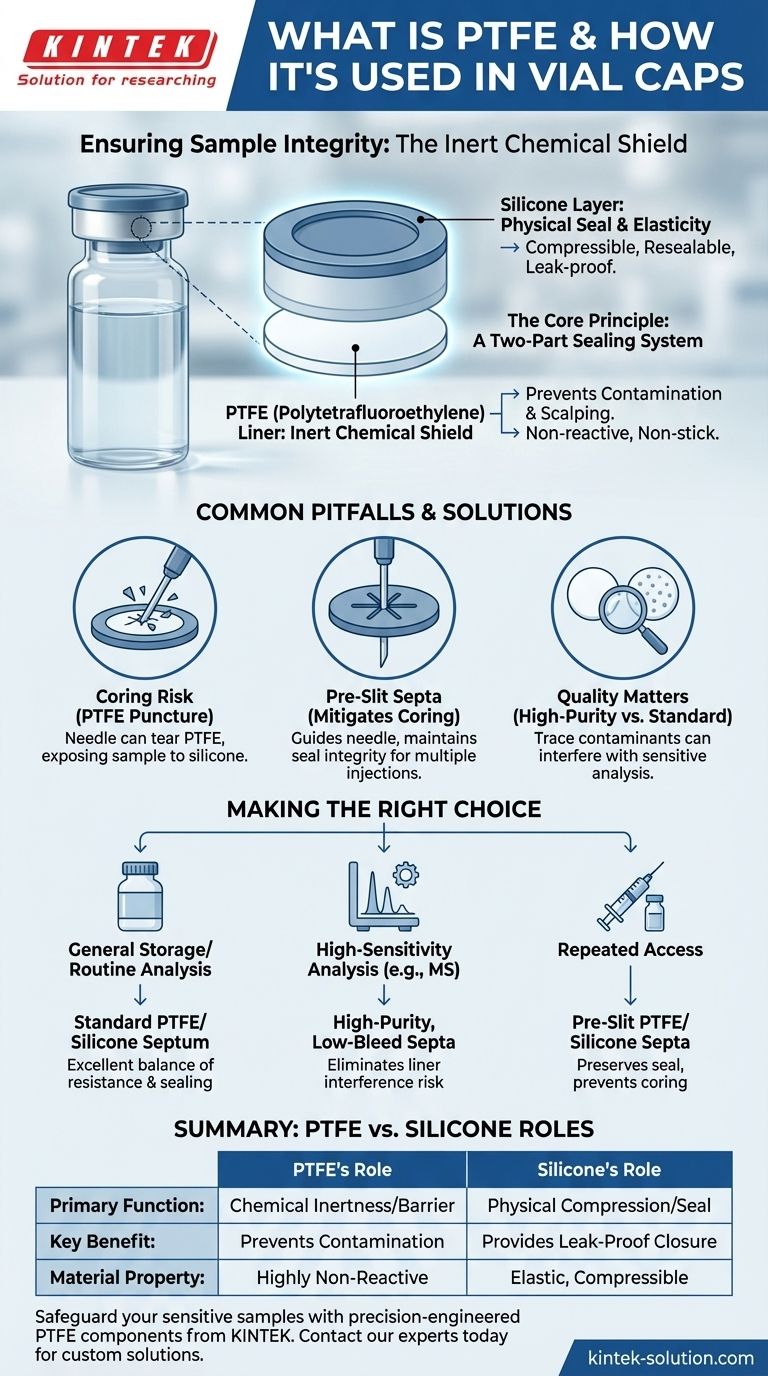

The Core Principle: A Two-Part Sealing System

To understand why PTFE is so effective, you must see the vial cap liner—or septum—as a system with two distinct functions fulfilled by two different materials.

The Chemical Barrier: PTFE's Role

PTFE's primary job is to face the sample. Its extreme chemical resistance means it will not react with or leach impurities into virtually any solvent, acid, or base stored in the vial.

This property prevents two critical problems: sample contamination, where molecules from the liner material enter your sample, and scalping, where analytes from your sample are absorbed by the liner.

The Physical Seal: Silicone's Role

While incredibly inert, PTFE is not very elastic. It cannot be compressed repeatedly to form a perfect, resealable seal on its own.

This is why PTFE is almost always laminated onto a thicker, softer layer of high-purity silicone or butyl rubber. This silicone layer provides the compressibility and elasticity needed to create a tight, leak-proof seal against the vial's rim and to reseal after being punctured by a syringe.

Understanding the Trade-offs and Common Pitfalls

While the PTFE/Silicone combination is the industry benchmark, it's essential to be aware of its limitations to avoid compromising your results.

The Risk of Coring

The thin PTFE layer can be punctured or torn by an autosampler or manual syringe needle. This is known as coring.

When this happens, the needle can push fragments of the PTFE film into your sample or directly contact the underlying silicone. This exposes your sample to the less-inert silicone, defeating the purpose of the PTFE liner and potentially introducing contaminants.

Pre-Slit vs. Non-Slit Septa

To mitigate coring, many manufacturers offer pre-slit septa. A small slit in the center of the liner guides the needle through, minimizing tearing of the PTFE layer.

This design is especially important for applications requiring multiple injections from the same vial, as it helps maintain the integrity of the seal and prevents liner fragmentation.

Not All Liners Are Equal

For routine applications, a standard PTFE/Silicone septum is sufficient. However, for highly sensitive analyses like mass spectrometry, even trace-level contaminants from lower-quality materials can interfere with results.

In these cases, it is critical to use septa certified for high-purity and low-bleed characteristics.

Making the Right Choice for Your Application

Selecting the correct cap liner is a critical decision based on your specific analytical goal.

- If your primary focus is general storage or routine analysis: A standard PTFE/Silicone septum offers an excellent balance of chemical resistance and reliable sealing.

- If your primary focus is high-sensitivity analysis (e.g., chromatography): Use high-purity, low-bleed PTFE/Silicone septa to eliminate the risk of chemical interference from the liner itself.

- If your primary focus is repeated access to the same vial: Choose pre-slit PTFE/Silicone septa to preserve seal integrity and prevent contamination from liner coring.

By understanding the distinct roles of PTFE and silicone, you can confidently select the right vial cap to safeguard the integrity of every sample.

Summary Table:

| Feature | PTFE's Role | Silicone's Role |

|---|---|---|

| Primary Function | Chemical Inertness / Barrier | Physical Compression / Seal |

| Key Benefit | Prevents contamination & scalping | Provides leak-proof, resealable closure |

| Material Property | Highly non-reactive, non-stick | Elastic, compressible |

Safeguard your sensitive samples with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE seals, liners, and labware are manufactured to the highest standards of purity and performance. We specialize in creating solutions that prevent contamination and ensure sample integrity, from initial prototypes to high-volume production runs.

Contact our experts today to discuss your specific application requirements and discover how KINTEK's precision production can enhance your analytical results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE preferred over glass in certain labware applications? Achieve Superior Resilience for Harsh Conditions

- What materials are used in PTFE-lined bottle caps? A Guide to PP Caps and PTFE Liners

- What are some specialized PTFE stirring bars available? Optimize Your Lab Mixing Efficiency

- What are the benefits of selecting the appropriate PTFE-coated septum for chromatography? Ensure Accurate & Reproducible Results

- What are the temperature ranges for PTFE-lined bottle caps? From -200°C to +250°C for Your Critical Applications

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the benefits of using high-performance materials in chemical laboratories? Ensure Purity and Reliability

- What makes PTFE lined vials easy to clean? The Science Behind Their Non-Stick, Inert Surface