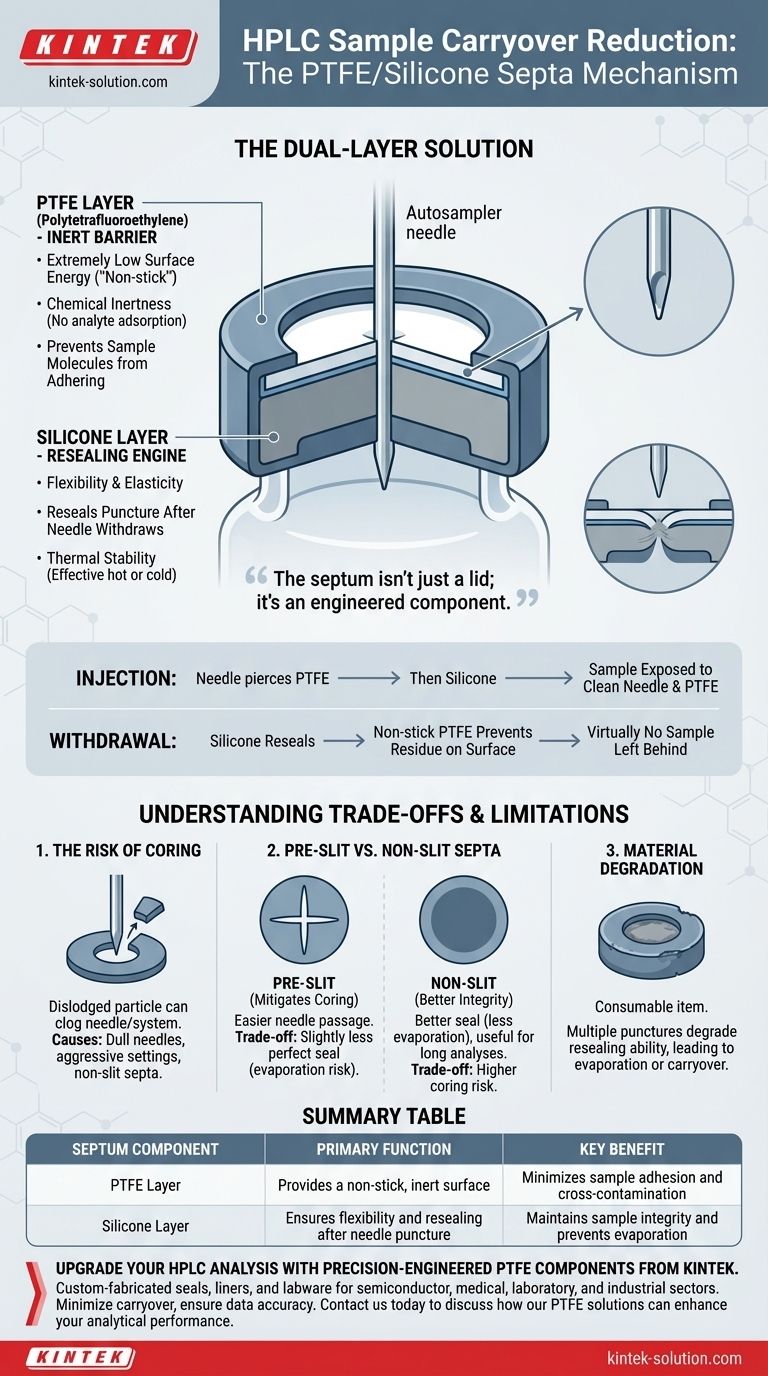

The key to reducing sample carryover lies in the dual-layer construction of the autosampler septum. A PTFE/silicone septum works by presenting a chemically inert, non-stick surface to your sample, which is then backed by a flexible, resealing layer. The PTFE layer directly prevents sample molecules from adhering to the septum surface, which is a primary cause of cross-contamination between injections.

The septum isn't just a lid; it's an engineered component. The PTFE layer provides the critical chemical barrier to prevent carryover, while the silicone layer provides the mechanical seal and resealing capability necessary for reliable, automated analysis.

The Dual-Layer Design: A Purpose-Built Solution

To understand how these septa prevent carryover, you must see them as a system of two materials, each with a distinct and vital role.

The PTFE Layer: Your Inert Sample Barrier

The layer that contacts your sample is PTFE (polytetrafluoroethylene). This material is chosen for its extremely low surface energy, which makes it "non-stick."

Because of this property, sample molecules have very little affinity for the PTFE surface. This dramatically minimizes the amount of residue left behind after the autosampler needle withdraws.

This chemical inertness also means the PTFE won't react with or adsorb analytes from your sample, preserving the sample's original composition and ensuring accuracy, especially in trace analysis.

The Silicone Layer: The Resealing Engine

Beneath the thin PTFE film is a much thicker layer of silicone. The primary function of the silicone is to provide flexibility and elasticity.

When the autosampler needle pierces the septum, the silicone stretches and forms a tight seal around the needle. After the needle is withdrawn, the silicone's elastic properties allow it to reseal the puncture, protecting the remaining sample.

Silicone also provides excellent thermal stability, ensuring the seal remains effective even if the autosampler tray is heated or cooled.

How They Work Together During Injection

During an injection, the needle first pierces the inert PTFE layer and then the silicone. The sample is only exposed to the clean needle and the non-stick PTFE.

Upon withdrawal, the silicone reseals the hole, and because the PTFE layer is non-stick, virtually no sample residue is left on the septum's outer surface. This prevents the needle from picking up contaminants from a previous vial on its way into the next one.

Understanding the Trade-offs and Limitations

While highly effective, PTFE/silicone septa are not without potential issues. Understanding these limitations is key to preventing analytical problems.

The Risk of Coring

Coring occurs when the needle punches out a small piece of the septum instead of cleanly piercing it. This dislodged particle can fall into your sample, potentially clogging the needle or the HPLC system.

This is more common with dull needles, aggressive needle-piercing settings, or when using septa that are not pre-slit.

Pre-Slit vs. Non-Slit Septa

To mitigate coring, many septa are pre-slit. A small cross or star-shaped cut makes it easier for the needle to pass through without tearing the material.

The trade-off is that a pre-slit septum may offer a slightly less perfect seal against solvent evaporation. For highly volatile solvents or very long analysis sequences, a non-slit septum may provide better long-term sample integrity, but with a higher risk of coring.

Material Degradation

Septa are consumable items. After multiple punctures, the silicone's ability to reseal effectively degrades. A worn-out septum can lead to evaporation or introduce carryover, defeating its original purpose.

Making the Right Choice for Your Analysis

Choosing the correct septum configuration is a simple but critical step for ensuring data quality.

- If your primary focus is trace analyte analysis: Use a new, high-quality, non-slit PTFE/silicone septum for each sample to achieve the best possible seal and minimize any risk of carryover.

- If your primary focus is high-throughput or long sequences: Use pre-slit septa to reduce needle wear and the risk of coring, but monitor for potential solvent evaporation on your first few runs.

- If your primary focus is method validation: Always use new septa to eliminate them as a potential variable and ensure the most accurate, reproducible results.

Ultimately, understanding this small component is a crucial step toward achieving complete confidence in your chromatographic data.

Summary Table:

| Septum Component | Primary Function | Key Benefit |

|---|---|---|

| PTFE Layer | Provides a non-stick, inert surface | Minimizes sample adhesion and cross-contamination |

| Silicone Layer | Ensures flexibility and resealing after needle puncture | Maintains sample integrity and prevents evaporation |

Upgrade your HPLC analysis with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE seals, liners, and labware are designed to minimize carryover and ensure the highest data accuracy. From prototypes to high-volume orders, we prioritize precision production to meet your exact needs.

Contact us today to discuss how our PTFE solutions can enhance your analytical performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the primary function of PTFE/silicone septa in HPLC autosampler vials? Ensure Sample Integrity and Accuracy

- What types of equipment are PTFE ferromagnetic support discs compatible with? Boost Your Lab's Efficiency

- What are the advantages of using PTFE laboratory bottles? Unmatched Chemical Resistance for Critical Samples

- What factors should be considered when selecting a PTFE shovel for laboratory use? Ensure Chemical Inertness & Sample Integrity

- Why is PTFE used in laboratory applications? Ensure Chemical Purity and Reliability

- What are common industrial applications of PTFE filters? Master Critical Filtration in Demanding Industries

- Why is PTFE suitable for medical laboratories? Ensure Unmatched Safety and Reliability

- Why are PTFE shovels considered cost-effective? Maximize ROI with Superior Durability