At their core, the sealing properties of a PTFE/silicone septum are its most critical function, directly responsible for maintaining the chemical integrity of your sample. This dual-material design creates a barrier that is both chemically inert and physically resilient, preventing volatile components from escaping and contaminants from entering the vial.

The effectiveness of a septum's seal is not merely about preventing leaks; it is the foundational element that ensures the sample injected into your instrument is identical to the sample you prepared, thereby guaranteeing the accuracy and reproducibility of your analytical results.

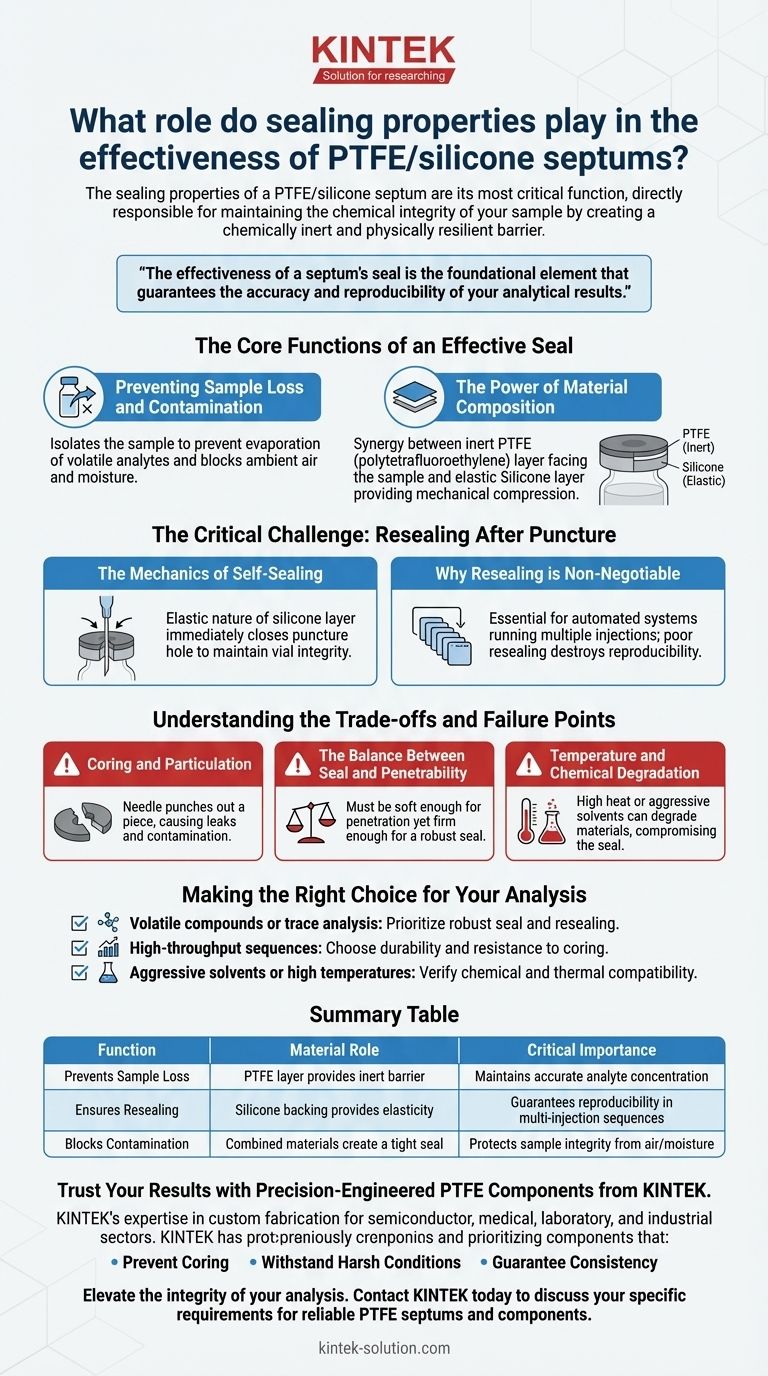

The Core Functions of an Effective Seal

A septum's primary role is to act as a perfect, temporary barrier. Its performance hinges on flawlessly executing several key functions from the moment the vial is capped until the analysis is complete.

Preventing Sample Loss and Contamination

The most fundamental job of the seal is to isolate the sample. The combination of a stiff, inert PTFE layer and a pliable silicone backing creates a tight fit against the vial rim.

This prevents the evaporation of volatile analytes, which would lead to artificially low concentration readings. It also stops ambient air and moisture from entering and potentially reacting with or diluting the sample.

The Power of Material Composition

The effectiveness of the seal comes from the synergy between its two materials. The thin PTFE (polytetrafluoroethylene) layer faces the sample, providing an exceptionally inert barrier that won't react with or adsorb analytes.

Behind it, the thicker silicone layer provides mechanical elasticity. This allows the septum to be compressed, forming a tight seal that remains consistent even under pressure changes or temperature fluctuations within an autosampler.

The Critical Challenge: Resealing After Puncture

A pristine, unpunctured seal is only half the story. The septum's true test comes after it has been pierced by a needle, where its ability to reseal becomes paramount.

The Mechanics of Self-Sealing

When the needle is withdrawn, the elastic nature of the silicone layer is designed to immediately close the puncture hole. This self-sealing capability is essential for maintaining the vial's integrity.

A septum that reseals effectively ensures that the sample remains protected from evaporation and contamination, even after the first injection.

Why Resealing is Non-Negotiable

For automated systems running multiple injections from a single vial, or for samples sitting in a queue, poor resealing is a critical failure.

Each successive injection from a poorly sealed vial will have a slightly different concentration, destroying the reproducibility of the analysis and invalidating the results of the entire sequence.

Understanding the Trade-offs and Failure Points

No component is perfect, and understanding the potential failure modes of a septum is key to avoiding analytical problems. The primary challenge lies in balancing durability with functionality.

Coring and Particulation

Coring occurs when the needle punches out a small piece of the septum instead of parting it cleanly. This fragment can clog the needle or be deposited into the vial or instrument inlet, creating contamination and blockages.

This failure creates a permanent leak in the septum, compromising the sample and all subsequent analyses from that vial.

The Balance Between Seal and Penetrability

An ideal septum must be soft enough for the needle to penetrate easily without being damaged, yet firm enough to provide a robust, lasting seal.

A septum that is too hard may be prone to coring. Conversely, a septum that is too soft may not reseal properly or could be pushed into the vial by the needle.

Temperature and Chemical Degradation

The materials must withstand the analytical conditions. High temperatures in a GC inlet can cause silicone to lose its elasticity, compromising its ability to reseal. Likewise, aggressive solvents can swell or degrade the septum over time, leading to leaks.

Making the Right Choice for Your Analysis

Selecting the appropriate septum is an active step in ensuring data quality. Your choice should be guided by the specific demands of your analytical method.

- If your primary focus is volatile compounds or trace analysis: Prioritize a septum with a proven, robust seal and excellent resealing properties to prevent any analyte loss.

- If you are running high-throughput sequences with multiple injections: Choose a septum known for its durability and resistance to coring to ensure consistency from the first to the last injection.

- If you are using aggressive solvents or high temperatures: Verify the septum's chemical and thermal compatibility to prevent material degradation and maintain seal integrity throughout the run.

Ultimately, understanding a septum's sealing properties is the key to trusting your analytical results.

Summary Table:

| Function | Material Role | Critical Importance |

|---|---|---|

| Prevents Sample Loss | PTFE layer provides inert barrier | Maintains accurate analyte concentration |

| Ensures Resealing | Silicone backing provides elasticity | Guarantees reproducibility in multi-injection sequences |

| Blocks Contamination | Combined materials create a tight seal | Protects sample integrity from air/moisture |

Trust Your Results with Precision-Engineered PTFE Components from KINTEK

Your analytical data is only as reliable as the consumables you use. The sealing integrity of your septums is paramount for preventing sample loss, contamination, and ensuring the reproducibility of your GC/HPLC analyses.

KINTEK specializes in the custom fabrication of high-performance PTFE components, including septums, seals, and labware, for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between chemical inertness, penetrability, and resealing capability that your applications demand.

We prioritize precision production to deliver components that:

- Prevent Coring and Particulation: Ensuring clean needle penetration and no sample contamination.

- Withstand Harsh Conditions: Offering excellent chemical and thermal resistance for aggressive solvents and high temperatures.

- Guarantee Consistency: From prototype development to high-volume orders, every part meets stringent quality standards.

Elevate the integrity of your analysis. Contact KINTEK today to discuss your specific requirements for reliable PTFE septums and components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability