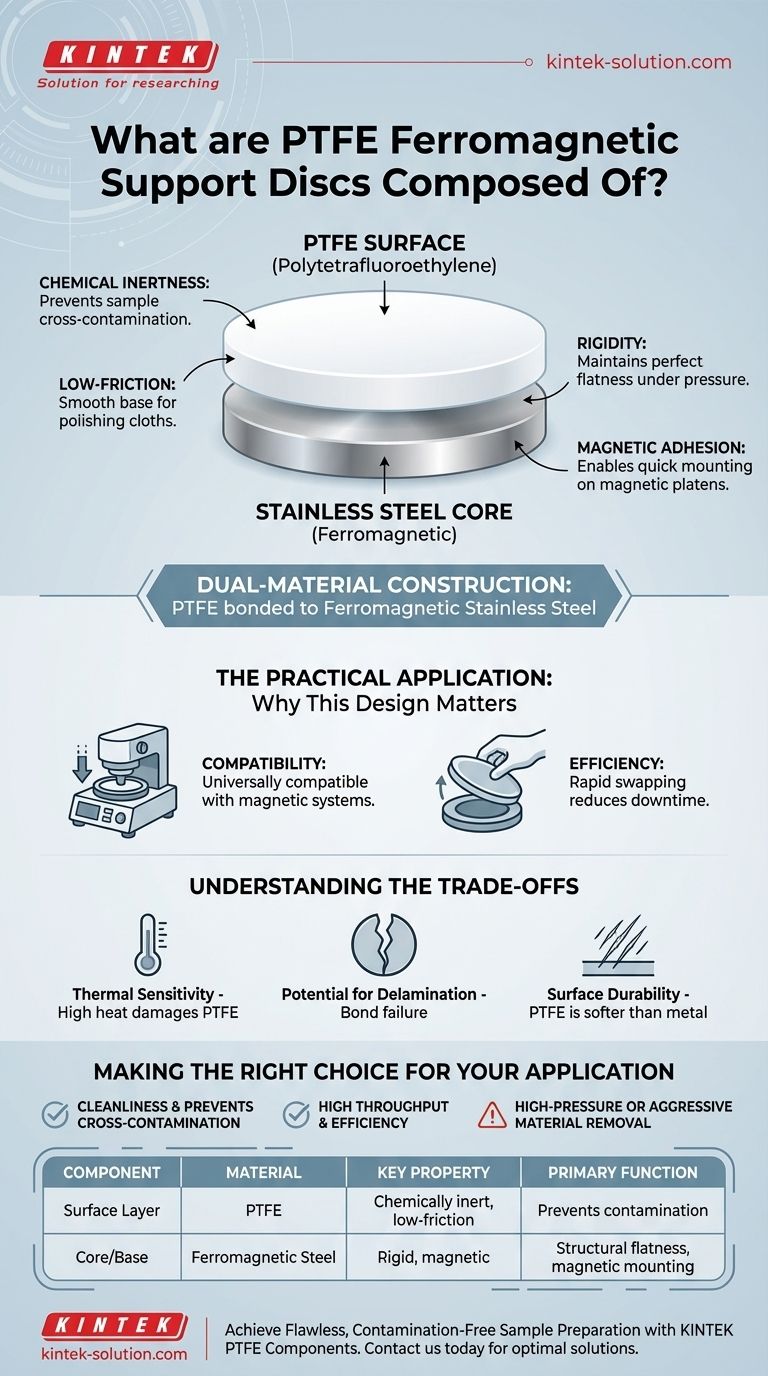

At their core, PTFE ferromagnetic support discs are composite tools engineered from two distinct materials. They consist of a layer of Polytetrafluoroethylene (PTFE) bonded to a rigid, ferromagnetic stainless steel disc. This design marries the unique surface properties of PTFE with the structural and magnetic capabilities of steel.

The dual-material construction is not arbitrary; it's a deliberate engineering choice. It provides a chemically inert, low-friction working surface (PTFE) on a rigid, magnetically mountable base (stainless steel), optimizing it for modern grinding and polishing equipment.

Deconstructing the Disc: The Role of Each Component

To understand the disc's function, you must first understand the purpose of each material. The combination is what makes this tool effective for specific applications.

The PTFE Surface: Chemical Inertness

Polytetrafluoroethylene (PTFE), widely known by the brand name Teflon, forms the top layer. Its primary benefit is its extreme chemical resistance.

This non-reactive surface prevents contamination between samples, which is critical in materials science and metallographic preparation. It also provides a smooth, low-friction base for polishing cloths.

The Stainless Steel Core: Rigidity and Magnetic Adhesion

Beneath the PTFE is a solid stainless steel disc. This component serves two essential functions.

First, it provides the rigidity necessary to keep the polishing surface perfectly flat under pressure, ensuring consistent results.

Second, it is ferromagnetic. This allows the disc to be securely held in place by the magnetic platens common on modern grinders and polishers, enabling quick and easy changes.

The Practical Application: Why This Design Matters

The specific composition of these discs directly impacts their use in a lab or production environment.

Compatibility with Modern Equipment

The ferromagnetic nature of the steel core is the key to its utility. It is designed explicitly for use with grinders and polishers that employ magnetic mounting systems.

This feature makes the discs universally compatible with equipment from a wide range of manufacturers, offering flexibility in a workshop.

Efficiency in Workflow

The ability to quickly mount and dismount the disc via magnetism streamlines the entire grinding and polishing process.

Technicians can rapidly swap between discs with different abrasive grits or polishing cloths, significantly reducing downtime and increasing throughput.

Understanding the Trade-offs

While highly effective, this composite design has inherent limitations that users must be aware of.

Thermal Sensitivity

PTFE has a much lower melting point than steel. High-pressure or high-speed grinding operations that generate significant frictional heat can potentially damage or warp the PTFE surface.

Potential for Delamination

The bond between the PTFE layer and the stainless steel core is a critical manufacturing point. Over time, or with exposure to certain mechanical stresses, there is a risk of the layers separating (delamination), which would render the disc unusable.

Surface Durability

The PTFE surface, while durable for its intended purpose, is softer than a solid metal disc. It can be scratched or scored by sharp debris, which may compromise the flatness of the polishing surface and require disc replacement.

Making the Right Choice for Your Application

Selecting the correct support disc depends entirely on the demands of your specific material preparation process.

- If your primary focus is cleanliness and preventing cross-contamination: The non-reactive PTFE surface is an ideal choice for preparing sensitive materials.

- If your primary focus is high throughput and efficiency: The ferromagnetic core is designed for rapid swapping on magnetic systems, perfectly suiting a fast-paced workflow.

- If your primary focus is high-pressure or aggressive material removal: Be mindful of the thermal and durability limits of the PTFE surface and ensure your process parameters are appropriate.

Understanding the construction of your tools is the first step toward achieving repeatable, high-quality results.

Summary Table:

| Component | Material | Key Property | Primary Function |

|---|---|---|---|

| Surface Layer | Polytetrafluoroethylene (PTFE) | Chemically inert, low-friction | Prevents sample cross-contamination, provides smooth polishing base |

| Core/Base | Ferromagnetic Stainless Steel | Rigid, magnetic | Provides structural flatness, enables magnetic mounting to equipment |

Achieve Flawless, Contamination-Free Sample Preparation with KINTEK PTFE Components

Understanding the precise composition of your lab tools is key to consistent, high-quality results. At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom support discs, seals, liners, and labware.

Our expertise ensures:

- Optimal Material Integrity: Perfect bonding between PTFE and steel to prevent delamination.

- Superior Chemical Resistance: Ideal for semiconductor, medical, and laboratory applications where purity is critical.

- Enhanced Workflow Efficiency: Components designed for compatibility with modern magnetic mounting systems.

Whether you need a standard solution or a custom-fabricated prototype for a specialized application, we prioritize precision and durability.

Contact us today to discuss how our PTFE components can improve your grinding and polishing processes. Let's build the perfect solution for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability