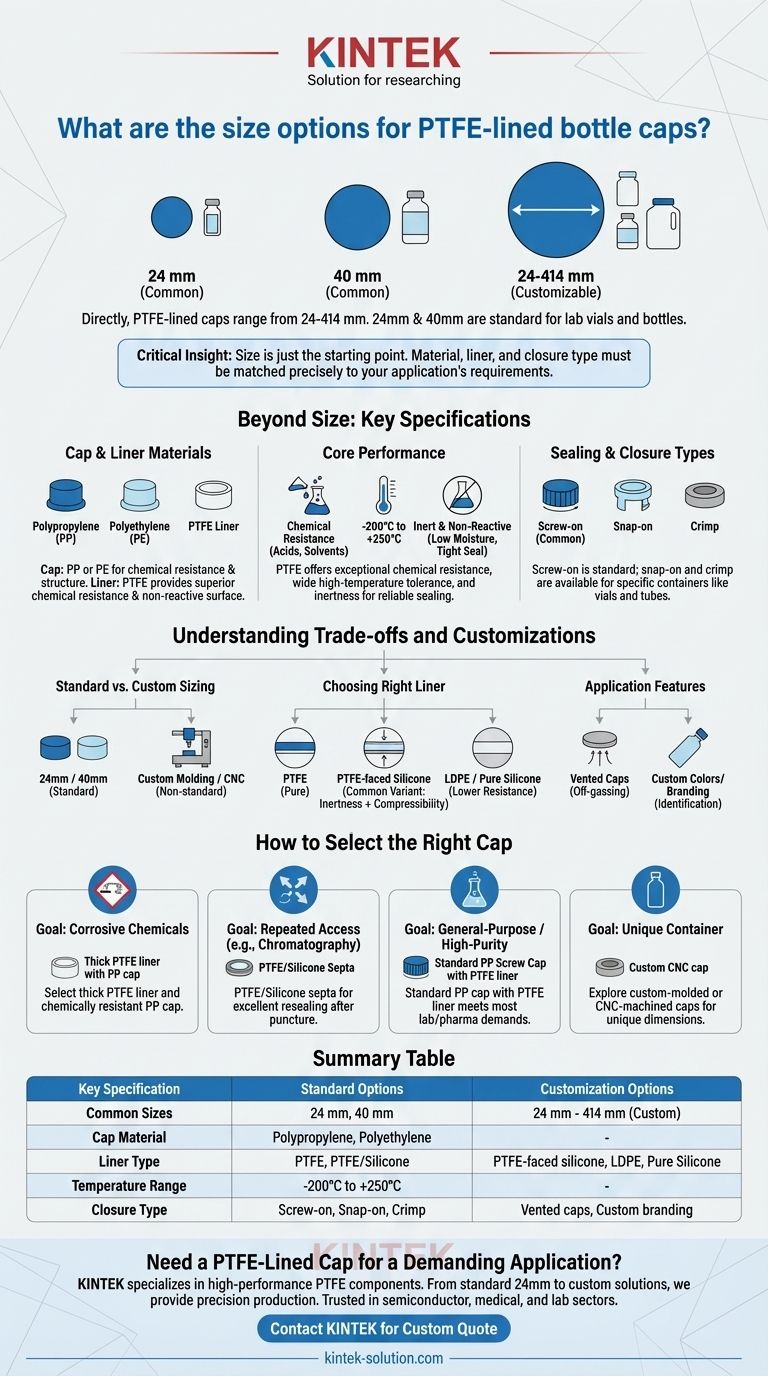

To be direct, PTFE-lined bottle caps are available in a customizable size range from 24-414 mm. The most common off-the-shelf sizes you will encounter are 24 mm and 40 mm, which are suitable for a wide variety of standard laboratory vials, bottles, and sample containers.

The critical insight is that while size is the starting point, selecting the correct cap requires a holistic evaluation. The cap's material, liner combination, and closure type must be matched precisely to your application's chemical, thermal, and sealing requirements.

Beyond Size: Key Specifications of PTFE-Lined Caps

Choosing the right cap goes far beyond simply matching the thread size of your container. You must consider the complete system to ensure sample integrity, safety, and performance.

### Cap and Liner Materials

The cap itself is most commonly made from polypropylene, which offers a good balance of chemical resistance and structural integrity. Polyethylene is a frequent alternative.

The liner is the critical component. The PTFE (Polytetrafluoroethylene) liner is what provides the superior chemical resistance and non-reactive surface your application likely demands.

### Core Performance Characteristics

The reason PTFE is specified is for its unique set of properties. It provides exceptional chemical resistance against strong acids, aggressive solvents, and other corrosive materials.

These caps also offer a very wide high-temperature tolerance, typically performing reliably from -200°C up to +250°C.

Finally, PTFE is chemically inert and non-reactive, ensuring it will not contaminate or interact with the contents. This, combined with low moisture transmission, creates an exceptionally tight and reliable seal.

### Sealing and Closure Types

While screw-on caps are the most common, other types exist for specific containers. You may also encounter snap-on, crimp, and other specialized closures for vials, flasks, and tubes.

Understanding the Trade-offs and Customizations

A standard cap is often sufficient, but demanding applications may require a more tailored solution. Understanding the available options is key to avoiding failure.

### Standard vs. Custom Sizing

If your container does not conform to standard sizes like 24 mm or 40 mm, custom molding or CNC machining is a viable option. This allows you to get a perfect fit for non-standard equipment.

### Choosing the Right Liner Combination

The liner is not always pure PTFE. A PTFE-faced silicone liner is a very common variant. This construction combines the inertness of a PTFE contact surface with the superior compressibility and resealing capability of silicone.

Other liner options include Low-Density Polyethylene (LDPE) or pure silicone, but these do not offer the same level of chemical resistance as PTFE. The choice depends entirely on the chemical compatibility and if the container needs to be repeatedly accessed (e.g., with a syringe).

### Considering Application-Specific Features

For certain applications, you may need additional features. Vented caps are available for solutions that may off-gas, preventing dangerous pressure buildup.

Custom colors and branding are also available for process identification or product differentiation.

How to Select the Right Cap for Your Application

Use your primary goal to guide your final selection.

- If your primary focus is storing highly corrosive chemicals: Ensure you select a cap with a solid or thick PTFE liner and a chemically resistant cap material like polypropylene.

- If your primary focus is repeated access and sample integrity (e.g., chromatography): A PTFE/Silicone septa is the ideal choice for its excellent resealing properties after puncture.

- If your primary focus is general-purpose, high-purity storage: A standard polypropylene screw cap with a PTFE liner will meet the demands of most laboratory and pharmaceutical applications.

- If your primary focus is fitting a unique container: You will need to explore custom-molded or CNC-machined caps to match your specific dimensions.

Ultimately, aligning the cap's specific material properties with the demands of your task is the key to a secure and reliable outcome.

Summary Table:

| Key Specification | Standard Options | Customization Options |

|---|---|---|

| Common Sizes | 24 mm, 40 mm | 24 mm - 414 mm (custom molding/CNC) |

| Cap Material | Polypropylene, Polyethylene | - |

| Liner Type | PTFE, PTFE/Silicone | PTFE-faced silicone, LDPE, pure silicone |

| Temperature Range | -200°C to +250°C | - |

| Closure Type | Screw-on, Snap-on, Crimp | Vented caps, custom branding |

Need a PTFE-Lined Cap for a Demanding Application?

KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and labware. Whether you require a standard 24mm cap or a custom-molded solution for a unique container, we provide precision production from prototypes to high-volume orders.

Our PTFE-lined caps are trusted in the semiconductor, medical, laboratory, and industrial sectors for their superior chemical resistance, inertness, and reliable sealing. Let us help you protect your samples and processes.

Contact KINTEK today for a custom quote or to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications