At its core, a PTFE/silicone septum reduces contamination by acting as a two-part protective barrier. The Polytetrafluoroethylene (PTFE) layer provides a chemically inert surface that directly contacts the sample, preventing chemical reactions or leaching. The thicker silicone layer provides the mechanical resealability needed to maintain a secure seal after the needle is withdrawn.

The primary function of a PTFE/silicone septum is not just to seal a vial, but to strategically isolate the sample from reactive materials. It combines the chemical inertness of PTFE with the resealing durability of silicone, a design choice that is fundamental to preserving sample integrity in sensitive analyses.

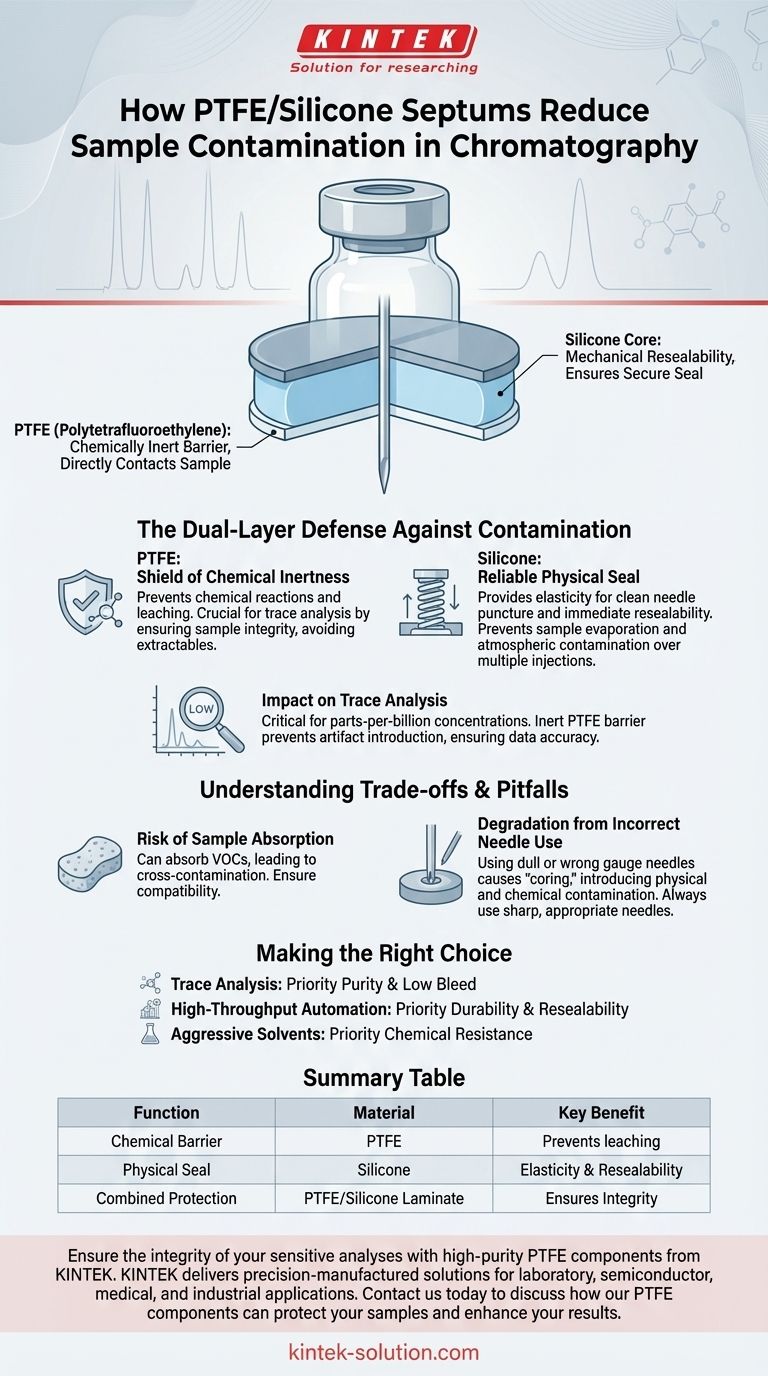

The Dual-Layer Defense Against Contamination

The effectiveness of these septa lies in the distinct roles played by each material. They work in tandem to create a seal that is both chemically non-reactive and physically robust.

The PTFE Barrier: A Shield of Chemical Inertness

The thin layer of PTFE is the most critical feature for preventing contamination. It is laminated onto the silicone base to serve as the only surface the sample or solvent vapor should contact.

Because PTFE is highly chemically inert, it does not react with or bind to the analytes in your sample. This property is crucial for preventing the septum from adding unwanted substances (extractables) or removing target analytes from the sample.

The Silicone Core: Ensuring a Reliable Physical Seal

While PTFE provides chemical protection, silicone provides the physical integrity. It is a highly elastic material that allows a needle to pierce it cleanly and then immediately reseals upon withdrawal.

This excellent resealability is vital for maintaining the vial's seal, preventing sample evaporation, and protecting it from atmospheric contamination over multiple injections.

The Impact on Trace Analysis

This dual-layer design is especially critical in trace analysis. When measuring components at parts-per-billion concentrations, even minuscule contamination from leaching can obscure or mimic the target analyte, rendering results unreliable.

The inert PTFE barrier ensures that the data reflects the sample's true composition, not artifacts introduced by lab consumables.

Understanding the Trade-offs and Pitfalls

While highly effective, PTFE/silicone septa are not a universal solution. Understanding their limitations is key to using them correctly and avoiding subtle forms of contamination.

The Risk of Sample Absorption

Despite its inertness, a septum can potentially absorb volatile organic compounds (VOCs) from a sample. This can lead to cross-contamination if the same septum is used across different analyses or if carryover is a concern.

Therefore, it is essential to ensure compatibility between your specific sample matrix and the septum material to minimize this absorption risk.

Degradation from Incorrect Needle Use

The physical integrity of the septum depends on correct handling. Using a dull, burred, or incorrect gauge needle can cause "coring," where small particles of the septum are torn away and fall into the sample.

This introduces both physical and chemical contamination, completely undermining the septum's purpose. Always use a sharp, appropriate needle style to ensure a clean puncture.

Making the Right Choice for Your Goal

Selecting the correct septum is a critical decision that directly impacts the quality of your chromatographic data. Your analytical goal should guide your choice.

- If your primary focus is trace analysis: Prioritize septums with the highest purity PTFE and certification for low bleed to ensure minimal chemical interference.

- If your primary focus is high-throughput automation: Select a septum praised for its durability and resealing capacity to withstand hundreds of injections without failure.

- If your primary focus is working with aggressive solvents: Confirm that both the PTFE and silicone layers have documented resistance to your specific chemical matrix.

Choosing the correct septum is a foundational step in generating reliable and defensible chromatographic data.

Summary Table:

| Function | Material | Key Benefit |

|---|---|---|

| Chemical Barrier | PTFE (Polytetrafluoroethylene) | Prevents leaching and chemical reactions with the sample |

| Physical Seal | Silicone | Provides elasticity and resealability after needle puncture |

| Combined Protection | PTFE/Silicone Laminate | Ensures sample integrity and prevents contamination |

Ensure the integrity of your sensitive analyses with high-purity PTFE components from KINTEK.

Whether you are performing trace analysis in a laboratory, managing high-throughput automation in the semiconductor industry, or require custom seals and liners for specialized medical or industrial applications, KINTEK delivers precision-manufactured PTFE solutions. We prioritize chemical inertness and durability, offering custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact us today to discuss how our PTFE components can protect your samples and enhance your results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability