In short, PTFE filters are used extensively in demanding industrial settings where chemical inertness, high-temperature resistance, and sterility are critical. Key applications include the sterile filtration of gases and aggressive solvents in the pharmaceutical and chemical industries, steam filtration, sterile tank venting for fermentation, and high-purity filtration in electronics manufacturing.

The core reason PTFE filters are chosen is their unique combination of properties: they are naturally hydrophobic (water-repelling) and almost universally chemically inert. This makes them the default choice for sterile gas filtration and for filtering chemicals that would destroy other membrane materials.

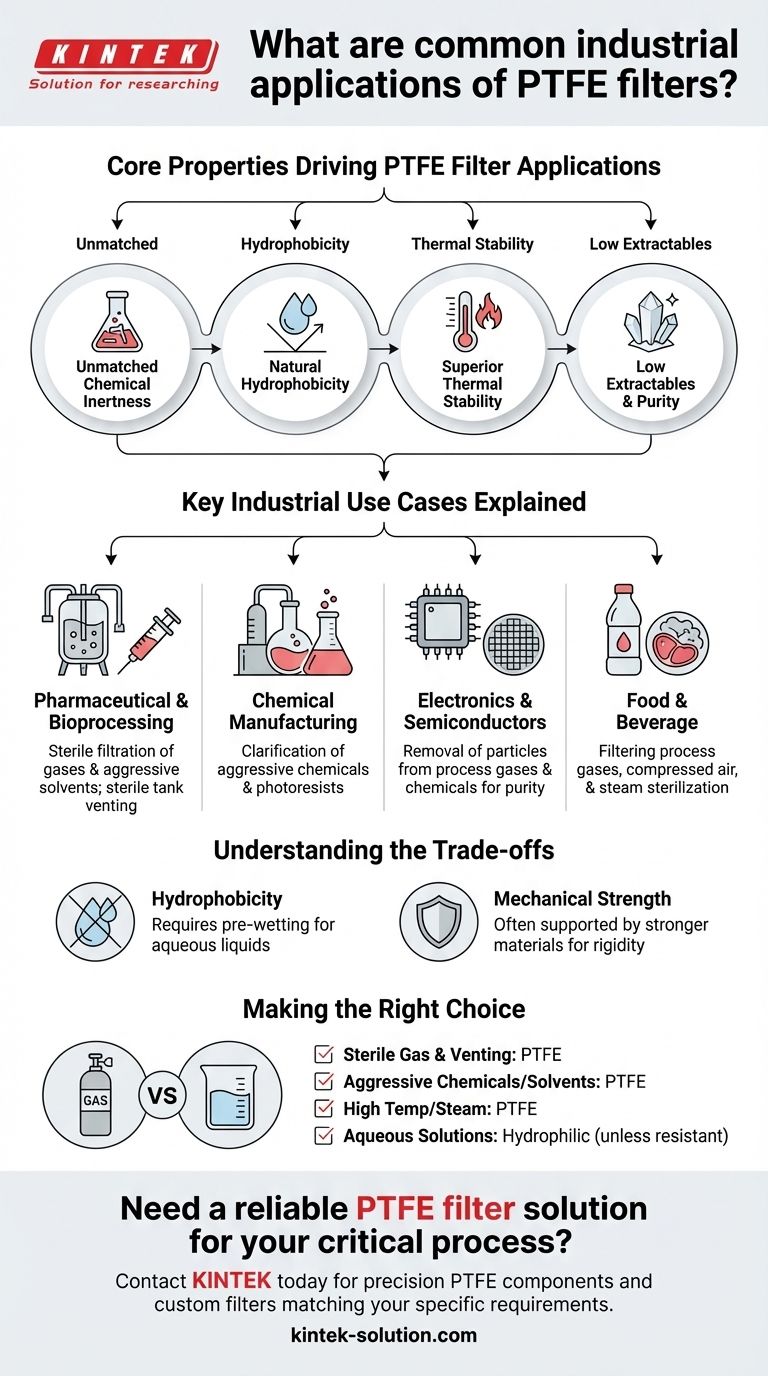

The Core Properties Driving PTFE Filter Applications

To understand why PTFE filters are used in these specific applications, you must first understand the fundamental properties of the Polytetrafluoroethylene material itself. Its performance is not accidental; it is a direct result of its molecular structure.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, solvents, acids, and bases.

This exceptional inertness means it can be used to filter aggressive substances that would degrade or dissolve materials like nylon, polypropylene, or cellulose. This is non-negotiable in chemical manufacturing and pharmaceutical synthesis.

Natural Hydrophobicity

PTFE membranes are inherently hydrophobic, meaning they naturally repel water while allowing gases to pass through with minimal resistance.

This property is the primary reason PTFE dominates sterile air and gas filtration. It effectively blocks water droplets, aqueous aerosols, and bacteria, creating a sterile barrier for applications like venting bioreactors or protecting vacuum pumps.

Superior Thermal Stability

PTFE can withstand a wide range of temperatures, including repeated steam sterilization cycles and autoclaving, without losing its structural integrity or filtration efficiency.

This makes it ideal for filtering high-temperature gases or steam used for sanitization in the food, beverage, and pharmaceutical industries.

Low Extractables and Purity

The "non-stick" quality of PTFE means it has very low levels of extractables—impurities that can leach out of the filter and contaminate the filtered product.

This ensures the purity of the final product, which is an absolute requirement in high-purity water systems, pharmaceutical production, and semiconductor manufacturing.

Key Industrial Use Cases Explained

These core properties translate directly into critical roles across several high-stakes industries.

Pharmaceutical and Bioprocessing

This is arguably the largest area of use. PTFE filters are essential for maintaining sterility in bioreactors and fermentation tanks by providing sterile gas exchange and exhaust filtration. They are also used for the sterile filtration of non-aqueous solvents used in drug synthesis.

Chemical Manufacturing

In chemical processing, PTFE filters are used to clarify aggressive chemicals, photoresists, and solvents. Their ability to withstand corrosive materials where other filters would simply fail makes them indispensable for ensuring process purity and protecting downstream equipment.

Electronics and Semiconductors

The manufacturing of microelectronics requires extremely pure gases and chemicals. PTFE filters are used to remove microscopic particles from process gases and harsh chemical solvents, preventing defects in sensitive semiconductor wafers.

Food and Beverage

While less common for direct product filtration, PTFE is used for filtering process gases, compressed air that comes into contact with the product, and for venting storage tanks. Its ability to be steam-sterilized ensures compliance with food safety standards.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Understanding its limitations is key to using it effectively.

Hydrophobicity Can Be a Limitation

The same hydrophobic nature that makes PTFE perfect for gas filtration makes it unsuitable for filtering water-based liquids out of the box. An aqueous solution will not readily pass through the membrane. To filter aqueous liquids, the PTFE membrane must first be pre-wetted with a low-surface-tension solvent like isopropyl alcohol (IPA).

Mechanical Strength

Unsupported PTFE membranes can be delicate. In most industrial filter cartridges, the PTFE membrane is laminated onto a stronger, more durable support material (often polypropylene) to give it the rigidity and strength needed to withstand high differential pressures during operation.

Cost vs. Performance

PTFE is a premium performance material, and its cost reflects that. It is typically specified for applications where its unique chemical and thermal properties are a necessity, not for general-purpose filtration where less expensive materials would suffice.

Making the Right Choice for Your Goal

Selecting the correct filter material is about matching the material's properties to the specific demands of your process.

- If your primary focus is sterile gas filtration or venting: PTFE is the industry standard due to its robust hydrophobicity, which provides an excellent barrier to aqueous contaminants.

- If your primary focus is filtering aggressive chemicals or solvents: PTFE's nearly universal chemical inertness makes it one of the only reliable options available.

- If your primary focus is high-temperature gas filtration or steam: PTFE's thermal stability ensures filter integrity where other polymers would fail.

- If your primary focus is filtering standard aqueous solutions: A naturally hydrophilic membrane (like PES or Nylon) is often a more direct and cost-effective choice, unless the process also requires extreme chemical or thermal resistance.

Ultimately, choosing a PTFE filter is a decision to prioritize chemical and thermal resilience for your most critical and demanding filtration challenges.

Summary Table:

| Property | Why It Matters for Industrial Filtration |

|---|---|

| Chemical Inertness | Withstands aggressive solvents, acids, and bases that degrade other materials. |

| Hydrophobicity | Ideal for sterile gas filtration; repels water and blocks bacteria/aerosols. |

| Thermal Stability | Resists high temperatures and repeated steam sterilization cycles. |

| Low Extractables | Ensures product purity in pharmaceuticals and semiconductor manufacturing. |

Need a reliable PTFE filter solution for your critical process?

KINTEK specializes in manufacturing high-performance PTFE components, including custom filters, seals, and liners, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a filter that perfectly matches your chemical, thermal, and purity requirements.

Contact KINTEK today to discuss your specific filtration challenge and discover how our PTFE expertise can enhance your process reliability and product quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the primary uses of PTFE silicone septa? Ensure Sample Integrity in GC/LC Analysis

- What are the main advantages of PTFE/silicone septa in laboratory applications? Ensure Sample Integrity and Accuracy

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- Why are PTFE shovels considered cost-effective? Maximize ROI with Superior Durability

- What are the key properties of Teflon that make it suitable for medical applications? Unlock Biocompatibility & Performance

- Why are PTFE syringe filters indispensable? For Superior Chemical Resistance and Sample Integrity

- What are the benefits of using a PTFE safety cover? Enhance Safety, Cut Costs & Mitigate Hazards

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware