The primary reason PTFE-lined butterfly valves are so durable is the chemically inert and physically resilient nature of their Polytetrafluoroethylene (PTFE) lining. This thick, non-metallic shield isolates the valve's core metal components from the process media, providing exceptional resistance to chemical corrosion, temperature extremes, and physical wear, which dramatically extends the valve's operational lifespan.

The core principle of this valve's durability is not the strength of the metal body, but the comprehensive protection offered by its internal PTFE liner. This liner acts as a barrier, neutralizing the most common causes of valve failure—corrosion and material degradation.

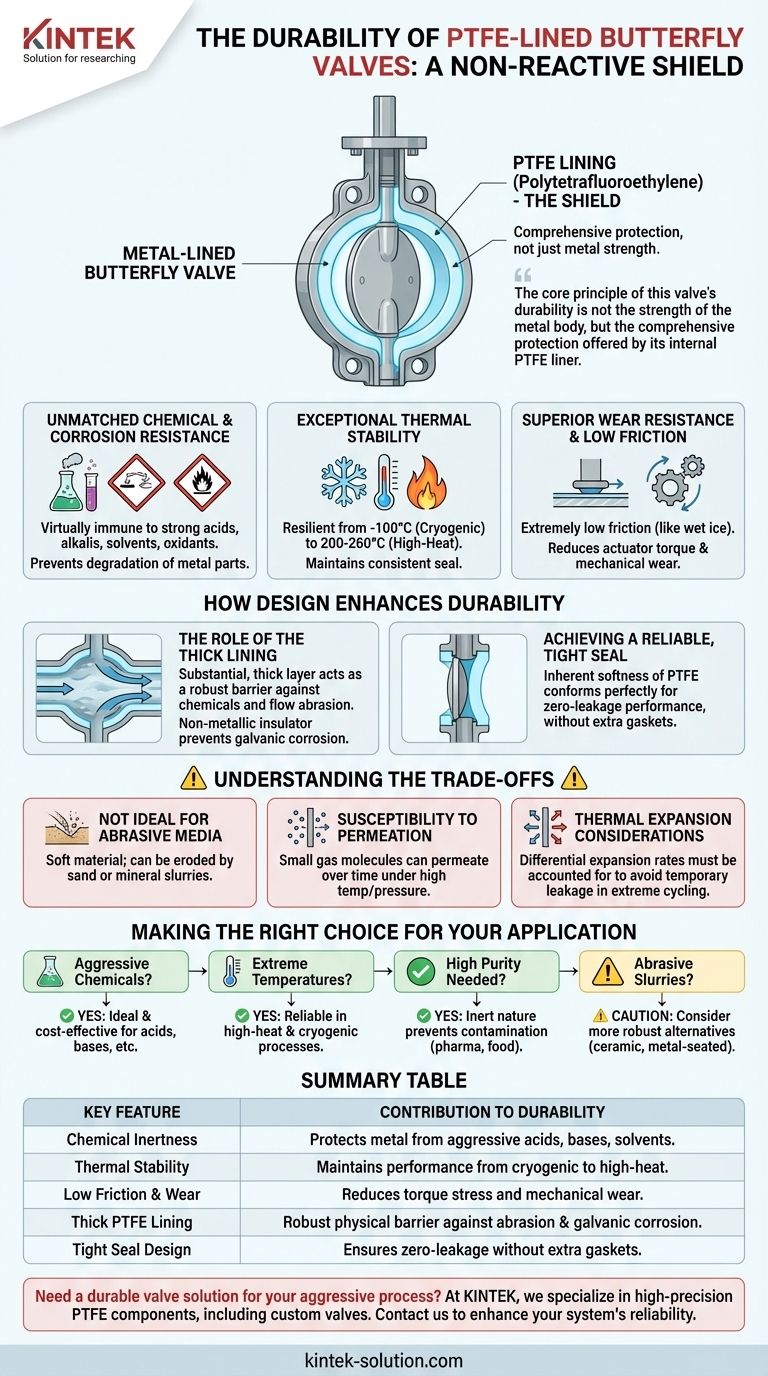

The Core Principle: A Non-Reactive Internal Shield

The durability of these valves stems from exploiting the unique properties of PTFE as a protective internal layer. This design separates the structural function of the valve body from the chemical-facing function of the liner.

Unmatched Chemical and Corrosion Resistance

PTFE is one of the most chemically inert materials used in industry. It is virtually immune to attack from strong acids, alkalis, solvents, and powerful oxidants.

This inertness means the corrosive media never makes contact with the valve's metal body or stem, preventing the degradation that would quickly destroy an unprotected valve.

Exceptional Thermal Stability

These valves demonstrate remarkable resilience across a vast temperature spectrum, typically operating from cryogenic temperatures (-100°C) up to high-heat processes (200-260°C).

The PTFE liner remains soft and functional at very low temperatures and does not degrade at high temperatures, ensuring a consistent and reliable seal regardless of thermal conditions.

Superior Wear Resistance and Low Friction

PTFE has an extremely low coefficient of friction, similar to wet ice on wet ice. This "slipperiness" is a key component of its physical durability.

This low-friction surface allows the valve's disc to rotate open and closed with minimal torque. This reduces stress on the actuator and wear on the stem seals, leading to a longer mechanical life with less maintenance.

How Design Enhances Durability

The manufacturing and design of the valve leverage the properties of PTFE to create a robust and reliable final product.

The Role of the Thick Lining

The PTFE is not a thin coating but a substantial, thick lining. This thick layer provides a robust physical barrier against not just chemicals but also potential abrasion from the flow.

As a non-metallic insulator, this lining also protects the metal parts from galvanic corrosion or other chemical attacks that could occur within the system.

Achieving a Reliable, Tight Seal

The inherent softness and flexibility of PTFE allow it to conform perfectly to the valve's disc, creating an exceptionally tight seal. This design frequently achieves "zero-leakage" performance.

The flanged ends of the valve body work with the liner to ensure this airtight seal is maintained without requiring additional gaskets or lubrication, simplifying installation and reducing potential failure points.

Understanding the Trade-offs

While highly durable in their intended applications, PTFE-lined valves are not a universal solution. Understanding their limitations is critical for proper selection.

Not Ideal for Abrasive Media

The primary strength of PTFE is its chemical resistance, not its hardness. It is a relatively soft material.

For processes involving hard, abrasive particles, such as sand or mineral slurries, the liner can be subject to physical erosion, which will eventually compromise the seal and lead to failure.

Susceptibility to Permeation

While resistant to chemical attack, very small gas molecules (like chlorine or hydrogen) can, under specific conditions of high temperature and pressure, slowly permeate through the PTFE liner over time.

In critical applications with such media, this can eventually lead to corrosion of the valve body behind the liner. This is a specialized concern but an important limitation to be aware of.

Thermal Expansion Considerations

PTFE expands and contracts with temperature changes at a different rate than the metal valve body. A well-designed valve accounts for this differential expansion to maintain seal integrity.

However, in systems with rapid or extreme thermal cycling, a poorly designed valve may experience temporary leakage as the materials expand and contract at different rates.

Making the Right Choice for Your Application

Selecting the right valve depends entirely on the specific demands of your process.

- If your primary focus is handling aggressive chemicals: The unmatched corrosion resistance of a PTFE liner makes it an ideal and cost-effective choice for safely controlling acids, bases, and other corrosive media.

- If your primary focus is operating in extreme temperatures: The wide, stable operating temperature range of PTFE ensures reliable performance in both high-heat and cryogenic processes.

- If your primary focus is ensuring high purity: The inert nature of PTFE prevents it from leaching or contaminating the process media, making it suitable for pharmaceutical, food, or semiconductor applications.

- If your primary focus is managing abrasive slurries: You should exercise caution and may need to consider a more robust, abrasion-resistant alternative like a ceramic or metal-seated valve.

Ultimately, the durability of a PTFE-lined butterfly valve comes from its intelligent design, which uses a specialized material to completely shield the valve's structure from its hostile operating environment.

Summary Table:

| Key Feature | Contribution to Durability |

|---|---|

| Chemical Inertness | Protects metal components from corrosion by aggressive acids, bases, and solvents. |

| Thermal Stability | Maintains performance from cryogenic (-100°C) to high-heat (up to 260°C) conditions. |

| Low Friction & Wear Resistance | Reduces torque stress and mechanical wear on seals and actuators. |

| Thick PTFE Lining | Acts as a robust physical barrier against abrasion and galvanic corrosion. |

| Tight Seal Design | Ensures zero-leakage performance without additional gaskets or lubrication. |

Need a durable valve solution for your aggressive process?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom PTFE-lined valves, seals, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a valve that perfectly matches your chemical, thermal, and purity requirements.

Contact us today to discuss how our PTFE solutions can enhance the durability and reliability of your fluid handling systems!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some tips for CNC machining Teflon? Master PTFE Machining for Superior Results

- How can deformation of PTFE during machining be minimized? Master Precision with Sharp Tools & Thermal Control

- What industries commonly use PTFE butterfly valves and why? For Superior Chemical Resistance & Purity

- How do expanded PTFE gaskets contribute to longer flange service life? Achieve Superior Sealing and Reliability

- What secondary manufacturing processes might PTFE parts require? Achieve Precise Specifications with Expert Machining

- What are the different types of PTFE rods available based on manufacturing technology? Choose the Right Type for Your Project

- What are some modern applications of PTFE due to its electrical insulative properties? | High-Frequency & Extreme Environment Solutions

- What are PTFE/PFA lined ball valves designed for? Corrosion-Proof Flow Control for Aggressive Fluids