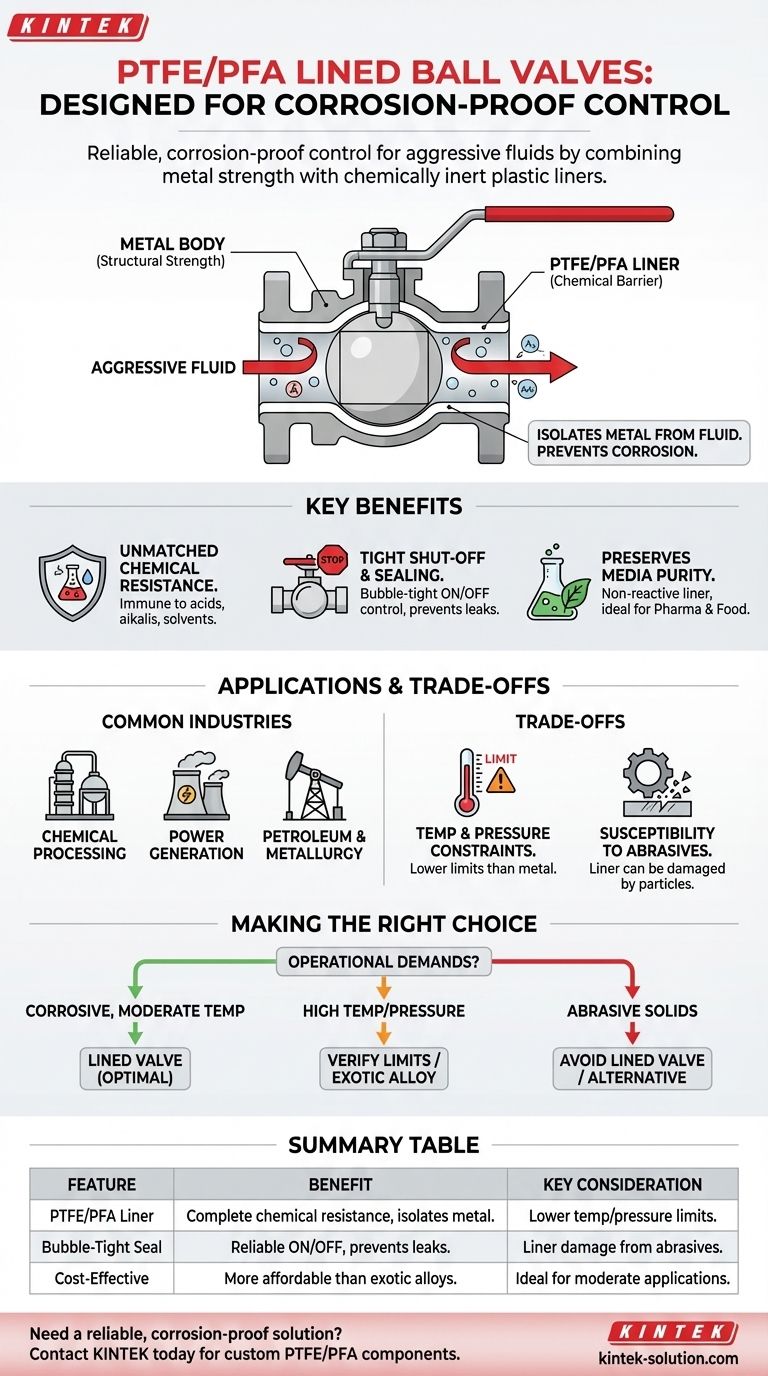

At their core, PTFE/PFA lined ball valves are engineered for one primary purpose: to provide reliable, corrosion-proof control and shut-off in pipelines handling highly aggressive and corrosive fluids. They use a chemically inert plastic liner to completely isolate the metal valve body from the fluid, preventing chemical attack and ensuring system integrity.

The central principle behind a lined ball valve is to combine the structural strength and pressure-containing capability of a metal body with the superior chemical resistance of a PTFE or PFA liner. This creates a cost-effective and highly reliable solution for managing corrosive media where exotic metal alloys would be prohibitively expensive.

The Core Problem: Managing Aggressive Fluids

Standard metal valves, even those made of stainless steel, can quickly degrade when exposed to certain chemicals. This corrosion compromises the valve's function, introduces contaminants into the process, and can lead to dangerous leaks.

How Lined Valves Provide a Solution

The valve's interior surfaces, including the body and the ball itself, are coated with a thick, seamless layer of Polytetrafluoroethylene (PTFE) or Perfluoroalkoxy (PFA).

This liner acts as an impermeable barrier. It ensures that the fluid only ever comes into contact with the chemically inert plastic, protecting the structural metal components from corrosion.

Unmatched Chemical Resistance

PTFE and PFA are renowned for their chemical stability. They are virtually immune to attack from a vast range of chemicals, including strong acids, alkalis, salts, and organic solvents.

This makes them exceptionally reliable for applications where fluid composition is aggressive or variable.

Key Benefits and Common Applications

The design of lined ball valves delivers several distinct advantages that make them a preferred choice across many industries.

Tight Shut-Off and Reliable Sealing

The soft-sealing nature of the PTFE/PFA components ensures a bubble-tight seal when the valve is in the closed position. This is critical for applications requiring dependable ON/OFF control to prevent leaks and ensure process safety.

Preserving Media Purity

Because the liner is non-reactive, it does not leach or corrode. This is essential in industries like pharmaceutical and food and beverage processing, where preventing contamination and maintaining product purity is paramount.

Broad Industrial Use

You will find PTFE/PFA lined ball valves extensively used in demanding environments. Key industries include:

- Chemical Processing: Handling feedstocks and process chemicals.

- Power Generation: Managing water treatment chemicals and other corrosive fluids.

- Petroleum and Metallurgy: Transporting aggressive substances in refining and extraction processes.

Understanding the Trade-offs

While highly effective, lined valves are not a universal solution. Understanding their limitations is key to proper application.

Temperature and Pressure Constraints

The primary limitation is the performance envelope of the plastic liner. PTFE and PFA have lower maximum temperature and pressure ratings compared to solid metal valves. Exceeding these limits can cause the liner to deform or fail.

Susceptibility to Abrasives and Damage

The plastic liner can be damaged by sharp, abrasive particles in the fluid, which can score or tear the material. Care must also be taken during installation to avoid scratching or damaging the liner, as any breach will expose the metal body to corrosion.

Making the Right Choice for Your Application

Selecting the correct valve requires a clear understanding of your specific operational demands.

- If your primary focus is cost-effective control of highly corrosive chemicals at moderate temperatures: A PTFE/PFA lined ball valve is almost certainly the optimal choice.

- If your system operates at very high temperatures or pressures: You must verify that they are within the valve's specified limits or consider a valve constructed from a suitable exotic alloy.

- If your fluid contains significant abrasive solids: A lined valve is likely a poor choice, and you should investigate alternatives designed for abrasive service.

Ultimately, a lined ball valve is a specialized tool designed to solve the difficult and expensive problem of corrosion in critical fluid-handling systems.

Summary Table:

| Feature | Benefit | Key Consideration |

|---|---|---|

| PTFE/PFA Liner | Complete chemical resistance, isolating fluid from metal body. | Lower temperature/pressure limits than metal valves. |

| Bubble-Tight Seal | Reliable ON/OFF control, prevents leaks. | Liner can be damaged by abrasive particles. |

| Cost-Effective | More affordable than exotic metal alloys for corrosive service. | Ideal for moderate temperature/pressure applications. |

Need a reliable, corrosion-proof solution for your aggressive fluid handling?

KINTEK specializes in the precision manufacturing of high-performance PTFE and PFA components, including custom-fabricated lined valves, seals, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors by combining superior chemical resistance with durable design.

Whether you require a standard product or a custom solution from prototype to high-volume production, we are committed to delivering the quality and reliability your critical processes demand.

Contact KINTEK today to discuss your specific application requirements and discover how our PTFE/PFA expertise can protect your system and enhance your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key benefits of using PTFE for piston rings in oil-free compressors? Achieve Clean, Efficient Compression

- What is the temperature range that PTFE gaskets can withstand? A Guide from -200°C to +260°C

- How do lined valves compare to plastic pipes in terms of pressure and temperature resistance? Unlock Superior Performance

- What are the benefits of Teflon's self-lubricating properties in mechanical applications? Boost Efficiency and Cut Costs

- What makes glass-filled PTFE rods suitable for electrical connectors? Superior Insulation & Durability

- What should be considered when using PTFE in specialized applications? Mastering its unique properties for optimal performance

- What are the characteristics and applications of PTFE beading? Solve Sealing and Friction Problems

- What are the main features of the PTFE seat butterfly valve? Unlock Superior Corrosion Resistance & Zero-Leakage Sealing