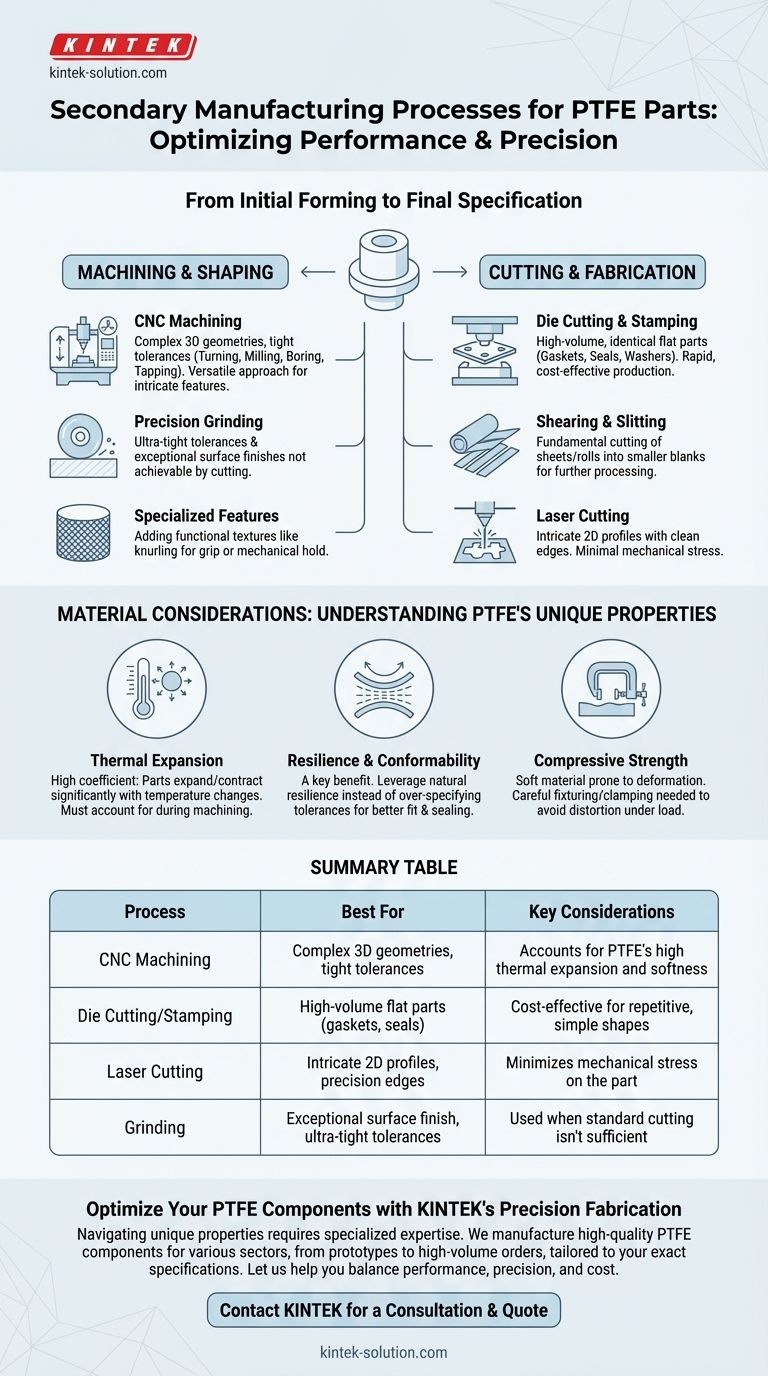

After initial forming, Polytetrafluoroethylene (PTFE) parts frequently require secondary manufacturing processes to achieve their final, precise specifications. These post-processing steps range from comprehensive CNC machining operations like turning, milling, and boring to specialized fabrication methods such as laser cutting, die cutting, and grinding. The choice of process depends entirely on the part's required geometry, tolerances, and production volume.

The key to successfully fabricating PTFE is not just knowing which processes are available, but understanding how the material's unique properties—like its resilience and high thermal expansion—fundamentally dictate the design and machining strategy.

The Role of Machining in PTFE Fabrication

Machining is the most common and versatile method for refining PTFE parts. Because PTFE is a relatively soft material, it can be worked on standard equipment with conventional tooling, but its unique characteristics demand a specific approach.

Standard CNC Operations

Most complex PTFE components are created using CNC (Computer Numerical Control) equipment. This includes processes like turning for cylindrical parts, milling for complex geometries, boring to create precise holes, and tapping to add threads.

Precision Grinding

For applications requiring exceptionally tight tolerances or a specific surface finish that is difficult to achieve through cutting alone, grinding may be employed. This process uses an abrasive wheel to remove material with very high precision.

Specialized Features

Secondary processes can also add specific functional features to a part. Knurling, for example, can be used to create a patterned, textured surface on a component for improved grip or mechanical hold.

Cutting and Shaping Processes

For simpler geometries, particularly for parts made from PTFE sheet or film, other fabrication methods are often more efficient and cost-effective than full CNC machining.

Die Cutting and Stamping

When producing high volumes of identical, flat parts like gaskets, seals, or washers, die cutting or stamping is the ideal method. A custom-made die presses through the PTFE sheet to create the final shape quickly and repeatably.

Shearing and Slitting

Shearing or slitting are fundamental processes used to cut large sheets or rolls of PTFE into smaller, more manageable strips or blanks. These pieces often serve as the starting material for subsequent machining or stamping operations.

Laser Cutting

For creating intricate two-dimensional profiles that may be too complex for die cutting, laser cutting offers exceptional precision. This process uses a high-powered laser to vaporize the material, resulting in a clean edge with minimal mechanical stress on the part.

Understanding the Trade-offs

Successfully working with PTFE requires acknowledging its distinct material properties. Ignoring these can lead to parts that fail to meet specifications, especially under operational conditions.

The Challenge of Thermal Expansion

PTFE has a very high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. This must be accounted for during machining; parts measured at one temperature may be out of tolerance at another.

The Benefit of Resilience

A key advantage of PTFE is its resilience and ability to conform. This means that chasing unnecessarily tight tolerances is often counterproductive and needlessly increases costs. A well-designed part leverages this property, allowing it to fit and seal effectively without extreme precision.

Managing Compressive Strength

PTFE is a soft material that can deform or "creep" under sustained load. Fixturing and clamping pressures during machining must be carefully controlled to avoid distorting the part, which would compromise the final dimensions.

Making the Right Choice for Your Application

Selecting the correct secondary process is critical for balancing performance, precision, and cost. Your final goal should guide your decision.

- If your primary focus is complex 3D geometry: CNC machining offers the most design freedom and is essential for parts with intricate features, bores, and threads.

- If your primary focus is high-volume, flat parts: Die cutting or stamping provides the most cost-effective and rapid production method for components like gaskets and seals.

- If your primary focus is managing costs: Design with realistic tolerances that leverage PTFE's natural resilience rather than over-specifying precision that adds no functional value.

By aligning your fabrication strategy with PTFE's inherent properties, you can create highly effective components optimized for both performance and manufacturability.

Summary Table:

| Process | Best For | Key Considerations |

|---|---|---|

| CNC Machining (Turning, Milling) | Complex 3D geometries, tight tolerances | Accounts for PTFE's high thermal expansion and softness |

| Die Cutting/Stamping | High-volume flat parts (gaskets, seals) | Cost-effective for repetitive, simple shapes |

| Laser Cutting | Intricate 2D profiles, precision edges | Minimizes mechanical stress on the part |

| Grinding | Exceptional surface finish, ultra-tight tolerances | Used when standard cutting isn't sufficient |

Optimize Your PTFE Components with KINTEK's Precision Fabrication

Navigating the unique properties of PTFE—like its high thermal expansion and resilience—requires specialized expertise to avoid costly errors and ensure part performance. At KINTEK, we manufacture high-quality PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, are tailored to leverage PTFE's advantages while meeting your exact specifications.

Let us help you select the right secondary process to balance performance, precision, and cost. Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability