In modern electronics and engineering, Polytetrafluoroethylene (PTFE) is a critical electrical insulator used in high-performance wiring, coaxial cables, printed circuit boards (PCBs), and sensitive connector assemblies. Its applications span demanding sectors like aerospace, telecommunications, and advanced computing, where standard insulators fail to provide the necessary performance and reliability.

While many materials can insulate against electricity, PTFE is uniquely suited for modern, high-stakes applications. Its value comes not just from its ability to block current, but from its unparalleled stability across extreme temperatures, frequencies, and chemical environments.

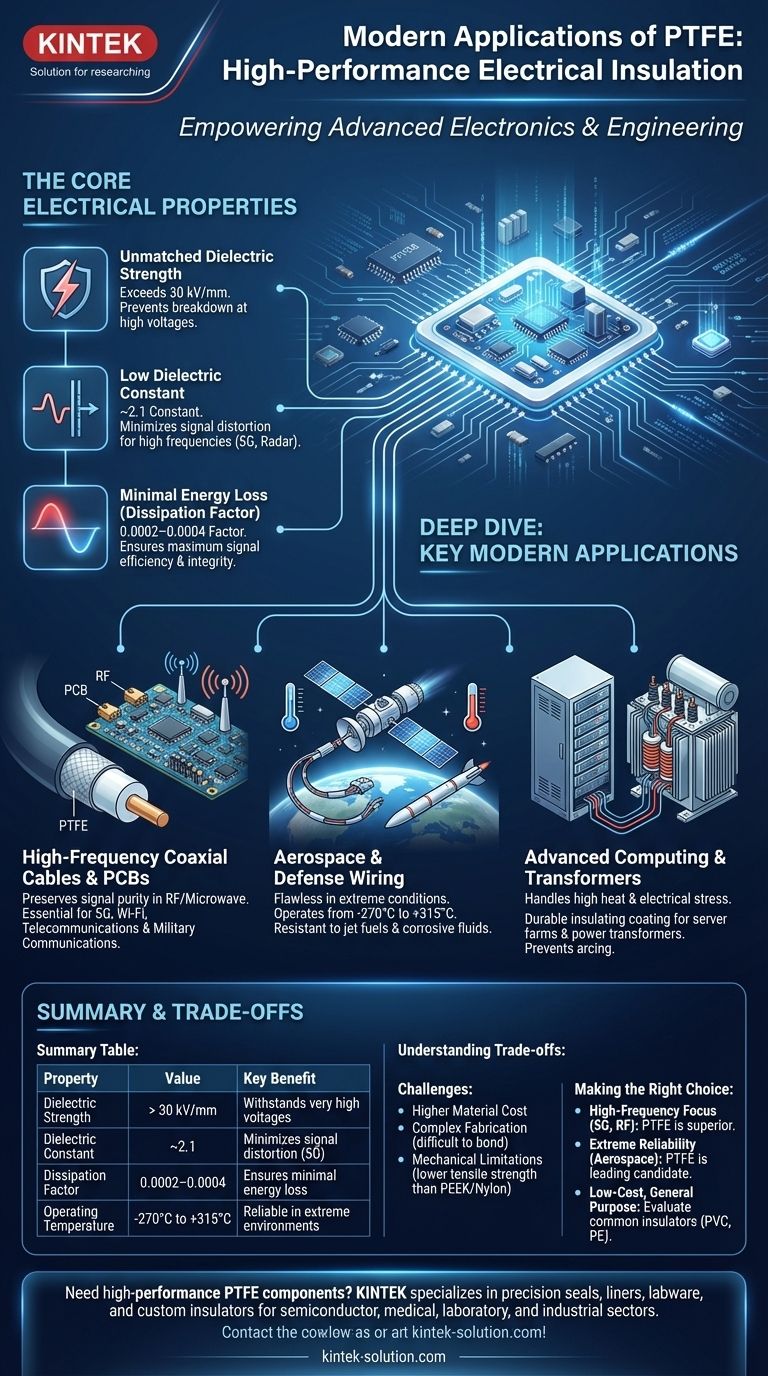

The Core Electrical Properties of PTFE

To understand its applications, we must first examine the fundamental properties that make PTFE a superior electrical insulator. These characteristics work in combination to protect sensitive components and ensure signal integrity.

Unmatched Dielectric Strength

Dielectric strength measures a material's ability to withstand high voltage before it breaks down and allows current to pass through.

PTFE possesses an extremely high dielectric strength, often exceeding 30 kV/mm. This means it can insulate against very high voltages without risk of current leakage, making it essential for high-power wiring and ensuring component safety.

Low Dielectric Constant for High-Frequency Signals

The dielectric constant indicates how much a material can store electrical energy in an electric field, which can interfere with high-frequency signals.

PTFE's very low dielectric constant (around 2.1) is one of its most important features for modern electronics. This property minimizes signal distortion and power loss, making it the ideal insulator for high-frequency applications like 5G infrastructure, satellite communications, and radar systems.

Minimal Energy Loss (Dissipation Factor)

The dissipation factor quantifies how much signal energy is lost as heat when passing through the insulating material.

With an extremely low dissipation factor (0.0002–0.0004), PTFE ensures that nearly all of a signal's energy is transmitted successfully without being wasted as heat. This is critical for maintaining signal integrity and efficiency in sensitive communication equipment.

Deep Dive: Key Modern Applications

These core properties directly enable PTFE's use in some of today's most advanced technologies.

High-Frequency Coaxial Cables and PCBs

In coaxial cables and printed circuit boards (PCBs) used for radio frequency (RF) and microwave signals, preserving signal purity is paramount.

PTFE's low dielectric constant and low dissipation factor ensure that signals travel with minimal interference or degradation. This makes it a non-negotiable material for components in telecommunications, Wi-Fi, and military-grade communication systems.

Aerospace and Defense Wiring

Components in aircraft, satellites, and missile guidance systems must function flawlessly in extreme conditions, from the vacuum and cold of space to the intense heat of engine components.

PTFE's vast operational temperature range (-454°F to 600°F or -270°C to 315°C) and resistance to jet fuels and corrosive fluids make it the go-to insulator for critical wiring harnesses and assemblies in the aerospace and defense industries.

Advanced Computing and Transformers

High-density server farms and powerful transformers generate significant heat and electrical stress.

PTFE is used as a durable insulating coating and wrap for internal wiring and components. Its thermal stability prevents insulation from melting or degrading, while its high dielectric strength protects against electrical arcing, ensuring long-term operational reliability.

Understanding the Trade-offs

While its properties are exceptional, PTFE is a specialized material. An objective evaluation requires acknowledging its limitations.

Higher Material Cost

PTFE is a premium fluoropolymer. Its manufacturing process is more complex than that of commodity plastics like PVC or polyethylene, resulting in a significantly higher cost per pound.

Fabrication Challenges

PTFE is a soft material that can be difficult to machine to tight tolerances. It also has a non-stick surface that makes it very difficult to bond with adhesives, often requiring special surface treatments like chemical etching.

Mechanical Limitations

Compared to engineering plastics like PEEK or Nylon, PTFE has lower tensile strength and wear resistance. It is not suitable for applications where the insulator must also serve a structural or high-abrasion role.

Making the Right Choice for Your Goal

Selecting an insulator depends entirely on the demands of your project. Use these guidelines to determine if PTFE is the appropriate choice.

- If your primary focus is high-frequency performance (e.g., 5G, RF, radar): PTFE is often the superior choice due to its exceptionally low dielectric constant and dissipation factor.

- If your primary focus is reliability in extreme temperatures or harsh chemicals (e.g., aerospace, industrial processing): PTFE's unmatched thermal and chemical stability makes it a leading candidate for ensuring long-term safety and performance.

- If your primary focus is a low-cost, general-purpose application at standard voltages and temperatures: You should evaluate more common insulators like PVC or Polyethylene, as PTFE's premium properties would be unnecessary and not cost-effective.

By understanding its fundamental electrical and material strengths, you can confidently specify PTFE where its unique capabilities will deliver maximum value and reliability.

Summary Table:

| Property | Value/Description | Key Benefit |

|---|---|---|

| Dielectric Strength | > 30 kV/mm | Withstands very high voltages, prevents current leakage |

| Dielectric Constant | ~2.1 | Minimizes signal distortion for high-frequency applications (5G, radar) |

| Dissipation Factor | 0.0002–0.0004 | Ensures minimal signal energy loss as heat |

| Operating Temperature | -270°C to +315°C | Reliable performance in extreme environments (aerospace, defense) |

Need high-performance PTFE components for your critical application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom insulators—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your components meet the demanding electrical and environmental standards of modern technology.

Contact KINTEK today to discuss how our custom PTFE solutions can enhance your product's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does the low friction property of PTFE benefit O-rings? Extend Seal Life and Boost Efficiency

- What is the tensile strength of Teflon balls? Leverage Its Unique Properties for Your Application

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How do PTFE lined butterfly valves enhance safety in industrial settings? Prevent Leaks and Corrosion

- Why is coolant management important in PTFE machining? Prevent Melting & Ensure Precision

- What are the key properties and applications of machined Teflon? Solve Extreme Engineering Challenges

- How does the coefficient of friction behave in PTFE sliding pipe supports? Ensure Predictable, Low-Friction Movement

- What makes glass-filled PTFE rods suitable for electrical connectors? Superior Insulation & Durability