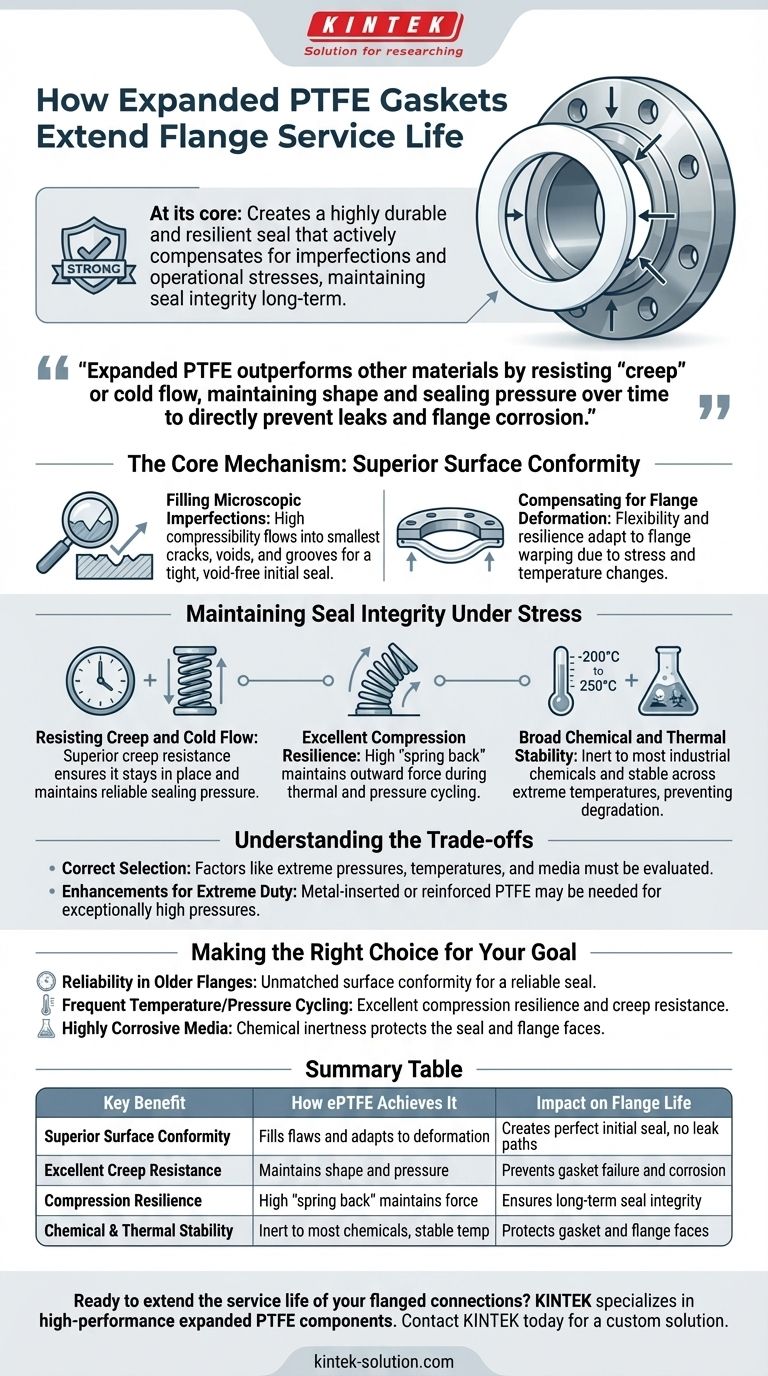

At its core, an expanded PTFE (ePTFE) gasket extends flange service life by creating a highly durable and resilient seal that actively compensates for real-world flange imperfections and operational stresses. Its unique microstructure allows it to mold perfectly into surface irregularities, maintaining seal integrity long after conventional gaskets would fail.

The primary reason expanded PTFE outperforms other materials is its ability to resist "creep" or cold flow. It maintains its shape and sealing pressure over time, even under thermal cycling and pressure fluctuations, directly preventing the leaks that lead to flange corrosion and premature failure.

The Core Mechanism: Superior Surface Conformity

A perfect seal requires perfect contact between the gasket and the flange faces. In practice, no flange surface is truly perfect. ePTFE is uniquely engineered to overcome this fundamental challenge.

Filling Microscopic Imperfections

The high compressibility of ePTFE allows it to flow into the smallest cracks, voids, and grooves on a flange face. This creates an exceptionally tight, void-free initial seal, eliminating potential leak paths from the moment of installation.

Compensating for Flange Deformation

Over time, flanges can warp or deform due to operational stress and temperature changes. The flexibility and resilience of ePTFE allow the gasket to adapt to these changes, maintaining a consistent sealing force across the entire flange face.

Maintaining Seal Integrity Under Stress

Creating a good initial seal is only half the battle. A gasket's true value is its ability to maintain that seal throughout countless operational cycles. This is where ePTFE's material properties provide a distinct advantage.

Resisting Creep and Cold Flow

Creep, or cold flow, is the tendency of a material to deform permanently under sustained pressure. Standard gaskets can slowly squeeze out of the flange, reducing sealing stress and causing leaks. ePTFE exhibits superior creep resistance, ensuring it stays in place and maintains a reliable seal.

Excellent Compression Resilience

Expanded PTFE has excellent "spring back" characteristics. After being compressed, it continues to exert an outward force on the flange faces. This resilience is critical for maintaining a seal during pressure and temperature cycling, which causes flanges to expand and contract.

Broad Chemical and Thermal Stability

The base PTFE material is virtually inert to most industrial chemicals, including strong acids and alkalis. This prevents the gasket itself from degrading, which could otherwise lead to seal failure and corrosive damage to the flange faces. It maintains its properties across an extremely wide temperature range, from -200°C to over 250°C.

Understanding the Trade-offs

While expanded PTFE is a superior solution for many applications, no single material is perfect for every scenario. Understanding its context is key to proper application.

The Importance of Correct Selection

The effectiveness of any gasket hinges on choosing the correct type for the specific operating conditions. Factors like extreme pressures, temperatures, and media must be evaluated to ensure optimal performance and longevity.

Enhancements for Extreme Duty

In applications with exceptionally high pressures or a significant risk of blowout, even ePTFE can have its limits. For these situations, metal-inserted or reinforced PTFE gaskets may be required to provide additional mechanical strength and blowout resistance.

Making the Right Choice for Your Goal

Selecting the right gasket is a strategic decision that directly impacts operational reliability and maintenance costs. The unique properties of ePTFE make it a powerful tool for extending the life of your flanged connections.

- If your primary focus is reliability in older or slightly damaged flanges: ePTFE's unmatched ability to conform to surface irregularities will create a reliable seal where other materials might fail.

- If your system experiences frequent temperature or pressure cycling: The gasket's excellent compression resilience and resistance to creep are critical for maintaining seal integrity over the long term.

- If you are handling highly corrosive or aggressive media: The chemical inertness of PTFE protects not only the seal but also the flange faces from potential corrosion, extending the life of the entire assembly.

By addressing the root causes of seal failure, expanded PTFE gaskets are a direct investment in the long-term health and reliability of your equipment.

Summary Table:

| Key Benefit | How ePTFE Achieves It | Impact on Flange Life |

|---|---|---|

| Superior Surface Conformity | High compressibility fills microscopic flaws and adapts to flange deformation. | Creates a perfect initial seal, eliminating leak paths. |

| Excellent Creep Resistance | Maintains shape and sealing pressure over time, even under stress. | Prevents gasket failure and subsequent flange corrosion. |

| Compression Resilience | High "spring back" maintains sealing force during thermal/pressure cycling. | Ensures long-term seal integrity as flanges expand and contract. |

| Chemical & Thermal Stability | Inert to most chemicals and stable from -200°C to 250°C+. | Protects the gasket and flange faces from degradation and corrosion. |

Ready to extend the service life of your flanged connections?

At KINTEK, we specialize in manufacturing high-performance expanded PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication capabilities—from prototypes to high-volume orders—ensure you get a gasket perfectly engineered for your specific operating conditions, maximizing reliability and minimizing downtime.

Contact KINTEK today to discuss your application and receive a custom solution that protects your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability