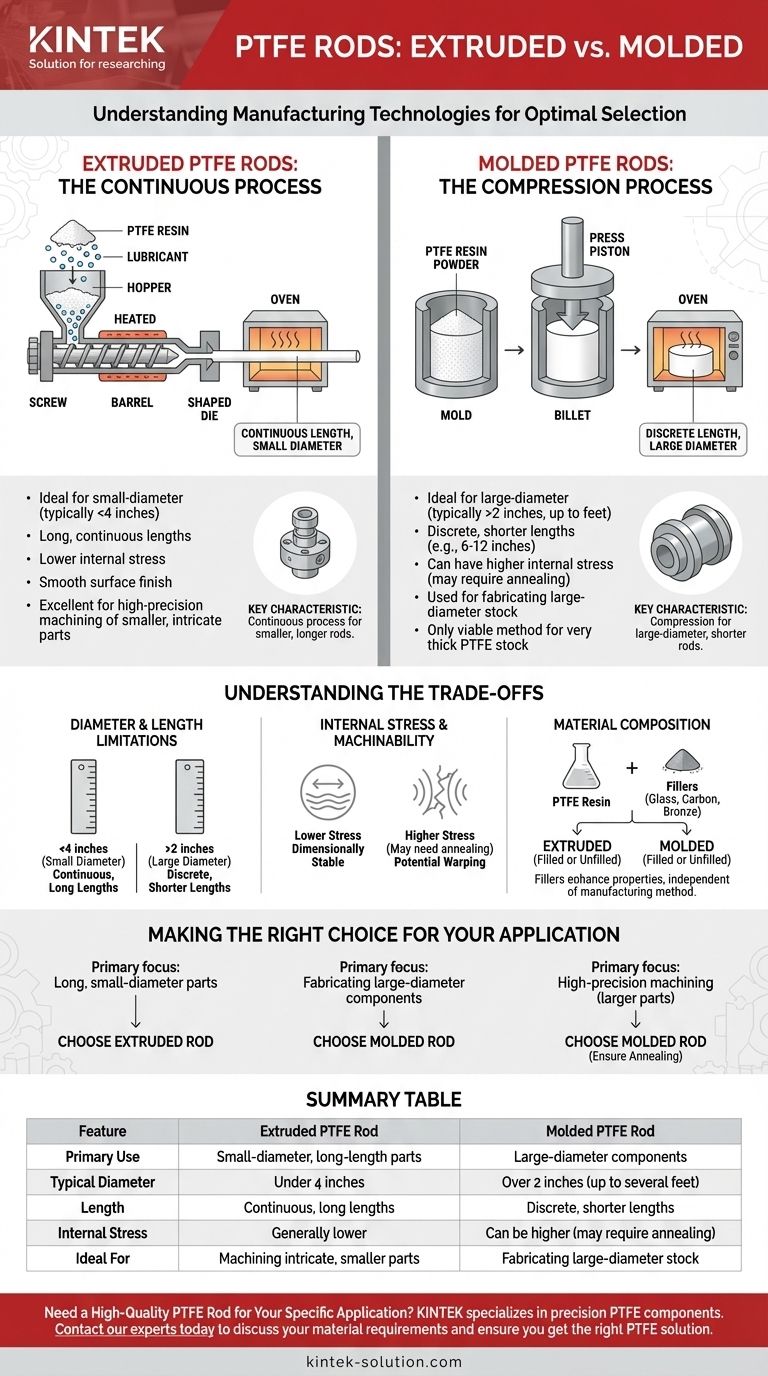

The two primary types of PTFE rods are defined by their manufacturing process: extruded and molded. While both begin with the same base PTFE resin, these distinct methods produce rods with different characteristics, primarily related to their size, internal stresses, and ideal applications. Understanding the origin of your material is the first step in ensuring its suitability for your engineering needs.

The choice between an extruded and a molded PTFE rod is fundamentally a decision based on the required dimensions. Extrusion is a continuous process ideal for smaller diameter, longer rods, while molding is a compression process used to create large-diameter stock.

The Two Core Manufacturing Methods

Polytetrafluoroethylene (PTFE) has a unique property: it does not truly melt and flow like common plastics. This extremely high melt viscosity makes it impossible to process using conventional injection molding. Instead, the industry relies on two specialized techniques.

Extruded PTFE Rods: The Continuous Process

Extrusion involves compacting PTFE resin (often with a processing aid or lubricant) and forcing it through a heated die to form a continuous shape. The rod then passes through an oven to bake off the lubricant and sinter the material, fusing the PTFE particles together.

This method is ideal for producing long, continuous lengths of rod with relatively small diameters. The process generally results in a rod with low internal stress and a smooth surface finish.

Molded PTFE Rods: The Compression Process

Molding, specifically compression molding, is used to create PTFE rods of larger diameters. In this process, a pre-calculated amount of PTFE resin is placed into a cylindrical mold.

The resin is then compressed under extreme pressure to form a solid billet. This billet is removed from the mold and sintered in an oven at high temperatures, allowing the particles to fuse into a solid, homogenous mass. This is the only viable method for producing very thick PTFE stock.

Understanding the Trade-offs

Choosing between an extruded and a molded rod is not just about preference; it's dictated by the physical constraints of the manufacturing processes and the requirements of your final part.

Diameter and Length Limitations

The most significant differentiator is size. Extrusion excels at producing rods with diameters typically under 4 inches, but they can be manufactured in very long, continuous lengths.

Molding, on the other hand, is the go-to method for rods with large diameters, often exceeding 2 inches and going up to several feet. However, these rods are produced in discrete, shorter lengths (e.g., 6 or 12 inches).

Internal Stress and Machinability

Because it is compressed and then sintered, molded rod can have higher levels of internal stress. For high-precision machining applications, this stress may need to be relieved through a post-sintering annealing process to prevent the material from warping or cracking.

Extruded rod generally has lower internal stress, making it dimensionally stable and often better suited for machining smaller, intricate components without requiring additional heat treatment.

Material Composition vs. Manufacturing

It's important to distinguish the manufacturing method from the material composition. Fillers like glass, carbon, or bronze can be added to the PTFE resin before it is either extruded or molded.

These fillers enhance specific properties like wear resistance or compressive strength but are independent of the manufacturing process itself. You can find both extruded and molded rods in filled and unfilled (virgin) grades.

Making the Right Choice for Your Application

Your final application dictates the correct material choice. By aligning the manufacturing method's strengths with your project's goals, you can prevent downstream issues with fabrication and performance.

- If your primary focus is creating long, small-diameter parts: Choose an extruded PTFE rod for its continuous length and excellent dimensional stability.

- If your primary focus is fabricating large-diameter components: You must use a molded PTFE rod, as it's the only method available for producing large stock sizes.

- If your primary focus is high-precision machining: Select an extruded rod for smaller parts or ensure a molded rod has been properly annealed for larger parts to minimize the risk of warping.

Understanding how your PTFE rod is made empowers you to select the precise raw material your project demands.

Summary Table:

| Feature | Extruded PTFE Rod | Molded PTFE Rod |

|---|---|---|

| Primary Use | Small-diameter, long-length parts | Large-diameter components |

| Typical Diameter | Under 4 inches | Over 2 inches (up to several feet) |

| Length | Continuous, long lengths | Discrete, shorter lengths (e.g., 6", 12") |

| Internal Stress | Generally lower | Can be higher (may require annealing) |

| Ideal For | Machining intricate, smaller parts | Fabricating large-diameter stock |

Need a High-Quality PTFE Rod for Your Specific Application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the dimensional stability of an extruded rod or the large-diameter capability of a molded rod, we provide custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss your material requirements and ensure you get the right PTFE solution for optimal performance and machinability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries benefit from the use of PTFE rotary shaft seals? Enhance Reliability in Harsh Environments

- What benefits do spring energized Teflon seals provide? Unlock Reliable Sealing in Extreme Conditions

- How can PTFE seals be maintained for longevity? Maximize Performance and Lifespan

- How is chemical resistance for Teflon encapsulated O-rings measured? Use the 1-10 Scale for Reliable Sealing

- What operational advantages do PTFE lined butterfly valves offer? Superior Flow Control for Harsh Chemical Environments

- What temperature range can PTFE O-rings withstand? Unlock Extreme Thermal Performance from -200°C to 260°C

- What types of Teflon backup rings are available and their uses? Ensure Sealing Integrity in High-Pressure Systems

- How can thermal expansion be managed during PTFE machining? Master Precision with a Multi-Faceted Strategy