At its core, the suitability of PTFE (Polytetrafluoroethylene) for dynamic flexing applications stems from its excellent flex life, a property that allows it to endure millions of bending cycles without fatigue. This inherent durability, combined with a flexibility comparable to rubber, makes it a premier material for components like bellows that must consistently move or deform during operation.

The true value of PTFE bellows is not just their flexibility, but the combination of that flexibility with near-universal chemical inertness and a wide operating temperature range. This unique trio allows them to perform reliably in dynamic, harsh environments where other flexible materials would quickly degrade and fail.

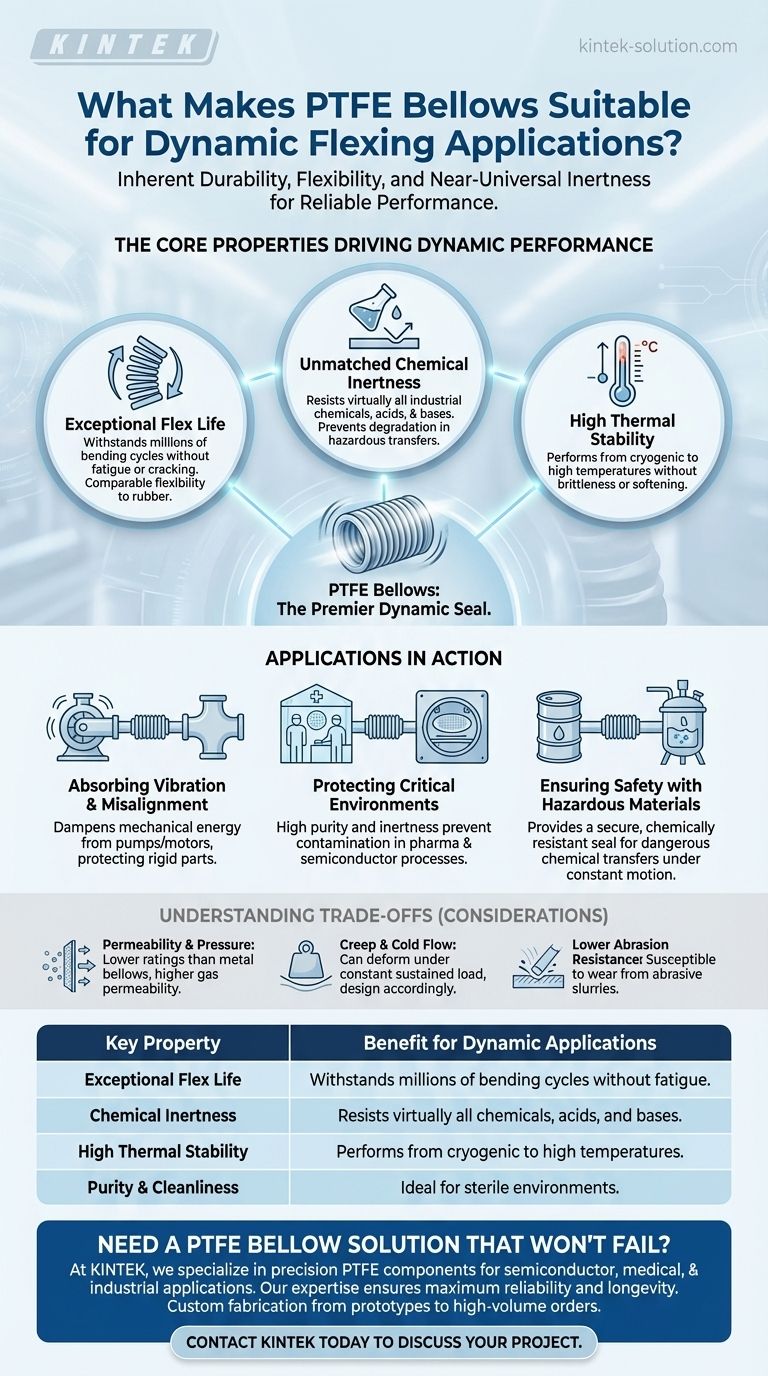

The Core Properties Driving Dynamic Performance

To understand why PTFE excels, we must look beyond its flexibility and examine the properties that work in concert to ensure long-term reliability in moving systems.

Exceptional Flex Life

The most critical attribute for any dynamic application is flex life—the material's ability to withstand repeated bending, compression, and extension without cracking or failing. PTFE is engineered to have a very long flex life, ensuring the bellows can reliably absorb movement over an extended period.

Unmatched Chemical Inertness

PTFE is famous for being resistant to nearly all industrial chemicals, acids, and bases. This means a PTFE bellows can handle the dynamic flexing required to transfer hazardous or corrosive fluids without degrading, which would be a catastrophic point of failure for a typical elastomer or rubber bellows.

High Thermal Stability

Systems involving dynamic movement often experience temperature fluctuations. PTFE maintains its flexibility and structural integrity across a very wide temperature range. It does not become brittle at low temperatures or soft at high temperatures, ensuring consistent performance whether the application involves cryogenics or heated processes.

How Bellows Apply These Properties in Practice

A bellows is a flexible seal designed to absorb movement. The unique properties of PTFE make it exceptionally good at this job in several critical scenarios.

Accommodating Vibration and Misalignment

No system is perfectly static or perfectly aligned. PTFE bellows are installed to absorb mechanical vibration from pumps or motors and to compensate for slight pipe or component misalignment. Their ability to flex continuously prevents this energy from transferring and causing stress or damage to more rigid parts of the system.

Protecting Critical and Sterile Environments

In pharmaceutical or semiconductor manufacturing, a bellows may be used to shield a highly sterile process from the outside environment. PTFE is ideal here because it is not only flexible but also extremely pure and inert, meaning it will not contaminate the sterile area while it moves.

Ensuring Safety with Hazardous Materials

When transferring dangerous chemicals, the flexible connection is often the weakest link. The combination of PTFE's durability and chemical resistance ensures the bellows provides a secure seal that will not be compromised by the fluid it contains, even under constant motion.

Understanding the Trade-offs

While PTFE is an exceptional material, it is not a universal solution. An objective assessment requires acknowledging its limitations.

Permeability and Pressure

Compared to metal bellows, PTFE is more permeable to certain small-molecule gases. For high-vacuum or specific gas containment applications, this can be a limiting factor. Likewise, while strong, they generally have lower pressure ratings than their metallic counterparts.

Creep and Cold Flow

Under a constant, sustained load (a condition known as "creep"), PTFE can slowly deform over time. In bellows applications where flexing is intermittent but static pressure is constant, this must be a design consideration.

Lower Abrasion Resistance

PTFE is a relatively soft material. In applications where the bellows might be exposed to abrasive slurries or external physical wear, its lifespan can be reduced compared to more robust materials like metal or certain hard-faced elastomers.

Making the Right Choice for Your Goal

Selecting the right bellows material depends entirely on the primary challenge you need to solve.

- If your primary focus is containing corrosive chemicals: PTFE bellows are the definitive choice, offering dynamic performance where most rubbers and even some metals would fail.

- If your primary focus is maintaining a high-purity or sterile environment: PTFE's inertness and cleanliness, combined with its flexibility, make it ideal for protecting sensitive processes.

- If your primary focus is absorbing vibration or thermal expansion: PTFE provides a durable and long-lasting solution, especially when chemical resistance is also a factor.

Ultimately, PTFE bellows are chosen when you need a flexible solution that absolutely cannot fail, even when faced with aggressive chemicals, temperature extremes, and constant movement.

Summary Table:

| Key Property | Benefit for Dynamic Applications |

|---|---|

| Exceptional Flex Life | Withstands millions of bending cycles without fatigue or cracking |

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and bases |

| High Thermal Stability | Performs from cryogenic to high temperatures without brittleness or softening |

| Purity & Cleanliness | Ideal for sterile pharmaceutical and semiconductor manufacturing environments |

Need a PTFE bellow solution that won't fail under pressure, chemicals, or constant movement?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom bellows—for semiconductor, medical, laboratory, and industrial applications. Our expertise ensures your dynamic flexing applications achieve maximum reliability, chemical resistance, and longevity.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific operational challenges.

Contact KINTEK today to discuss your project requirements and get a solution built to last.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How do PEEK and PTFE compare in terms of friction and chemical compatibility? Choose the Right High-Performance Polymer

- Why is PTFE considered chemically inert, and why is this beneficial for bushings? Ensure Reliability in Harsh Chemical Environments

- What are the advantages of glass fiber filled PTFE? Boost Strength & Resist Wear

- What temperature range can Virgin Molded PTFE withstand? From Cryogenic to High-Heat Performance

- What industries commonly use PTFE rotary shaft seals? The Ultimate Guide for Extreme Conditions

- What are the disadvantages of PTFE lined butterfly valves? Understanding Key Operational Limits

- How is Teflon used in the aerospace industry? Essential for Seals, Coatings & Insulation

- What are the advantages of square cross-section ring seals in TFE Encapsulated gaskets? Achieve Superior, Reliable Sealing