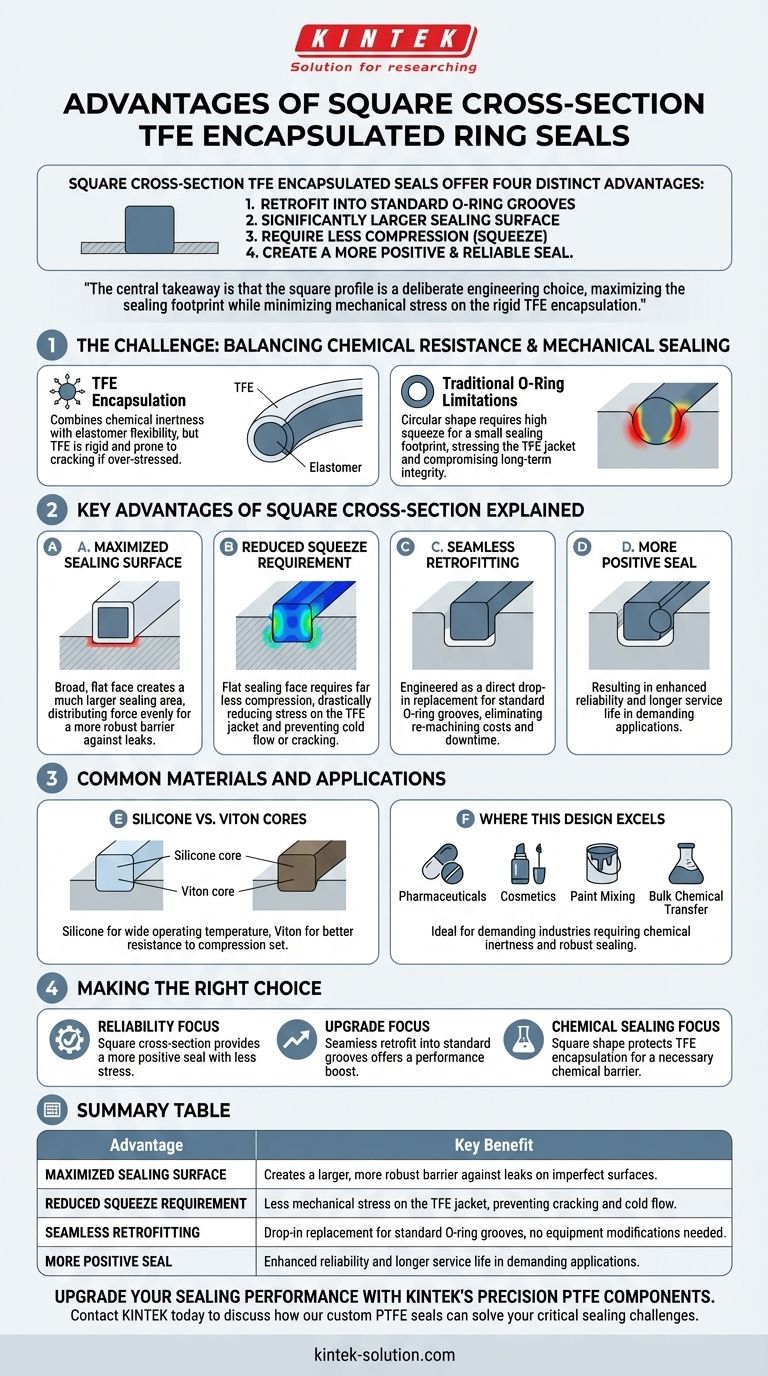

In short, square cross-section TFE encapsulated ring seals offer four distinct advantages. They are designed to retrofit into standard O-Ring grooves, provide a significantly larger sealing surface, require less compression (squeeze) to function, and as a result, create a more positive and reliable seal.

The central takeaway is that the square profile is not just a different shape, but a deliberate engineering choice. It maximizes the sealing footprint while minimizing the mechanical stress placed on the rigid TFE encapsulation, solving a key failure point of standard encapsulated O-rings.

The Challenge: Balancing Chemical Resistance and Mechanical Sealing

To understand the value of the square cross-section, we must first understand the fundamental challenge of encapsulated seals.

The Role of TFE Encapsulation

TFE (polytetrafluoroethylene) provides exceptional, nearly universal chemical resistance. Encapsulating an elastomeric core (like Silicone or Viton) with a TFE jacket combines the chemical inertness of TFE with the flexibility of an elastomer.

However, TFE is a relatively rigid material. It is not a true elastomer and can be prone to cracking or cold flow (permanent deformation) if over-stressed.

The Limitation of Traditional O-Ring Shapes

A standard O-ring has a circular cross-section. To create a seal, it must be significantly compressed (squeezed) in its groove. This high compression deforms the ring to create a small sealing footprint.

This high squeeze places significant stress on the TFE jacket, which can compromise the long-term integrity of the seal, especially in applications with pressure or temperature cycling.

Key Advantages of the Square Cross-Section Explained

The square or rectangular profile directly addresses the limitations of the traditional O-ring shape in encapsulated seals.

Maximized Sealing Surface

Unlike the point-contact of an O-ring, a square ring presents a broad, flat face to the sealing surface. This immediately creates a much larger sealing area.

A larger contact area distributes the sealing force more evenly, making it more effective on surfaces that may not be perfectly smooth and creating a more robust barrier against leaks.

Reduced Squeeze Requirement

Because the square ring already has a flat sealing face, it requires far less compression to achieve a seal. This is the most critical advantage for an encapsulated part.

Less squeeze means less mechanical stress on the TFE jacket. This drastically reduces the risk of cold flow or stress cracking, leading to a longer and more reliable service life.

Seamless Retrofitting

These seals are engineered to fit into standard, pre-existing O-ring grooves. This makes them a direct, drop-in replacement or upgrade.

You can gain the performance benefits of a square cross-section without the high cost and downtime associated with re-machining hardware or redesigning equipment.

Common Materials and Applications

The performance of the seal is also determined by its energizing core material.

Silicone vs. Viton Cores

The two most common core materials are solid silicone and solid Viton. Silicone offers a wider operating temperature range, while Viton provides better resistance to compression set (the tendency to permanently take the shape of the groove).

Where This Design Excels

The combination of chemical inertness and robust sealing makes these gaskets ideal for demanding industries. Applications in pharmaceuticals, cosmetics, paint mixing, and bulk chemical transfer all benefit from a seal that will not degrade from chemical contact or fail under mechanical stress.

Making the Right Choice for Your Application

Choosing the right seal geometry is critical for ensuring process integrity and equipment uptime.

- If your primary focus is reliability: The square cross-section provides a more positive seal with less stress on the TFE jacket, directly improving long-term performance.

- If your primary focus is upgrading existing equipment: The ability to retrofit square seals into standard O-ring grooves offers a significant performance boost without costly modifications.

- If your primary focus is sealing aggressive chemicals: The square shape protects the integrity of the TFE encapsulation, which provides the necessary chemical barrier for your process.

Ultimately, understanding the mechanics of the square cross-section empowers you to select a more resilient and effective sealing solution.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Maximized Sealing Surface | Creates a larger, more robust barrier against leaks on imperfect surfaces. |

| Reduced Squeeze Requirement | Less mechanical stress on the TFE jacket, preventing cracking and cold flow. |

| Seamless Retrofitting | Drop-in replacement for standard O-ring grooves, no equipment modifications needed. |

| More Positive Seal | Enhanced reliability and longer service life in demanding applications. |

Upgrade your sealing performance with KINTEK's precision PTFE components.

Our expertise in custom fabricating high-performance seals, including square cross-section TFE encapsulated gaskets, ensures a solution tailored to your specific needs in the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we prioritize precision and reliability to protect your processes.

Contact KINTEK today to discuss how our custom PTFE seals can solve your critical sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments