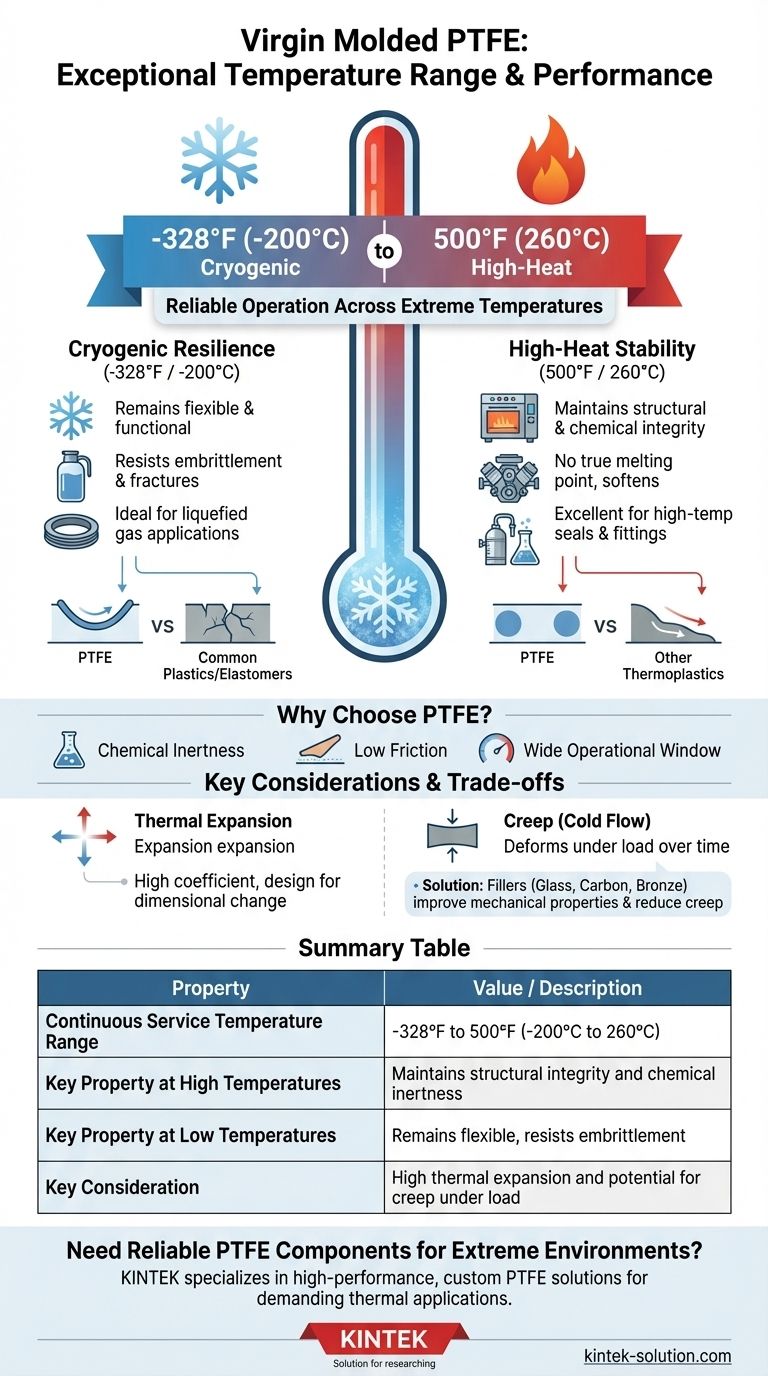

At its core, Virgin Molded Polytetrafluoroethylene (PTFE) operates reliably within an exceptionally wide temperature range. It can withstand continuous service temperatures from cryogenic lows of -328°F (-200°C) up to a high of 500°F (260°C), maintaining its key properties where many other polymers would fail.

The true value of PTFE is not just its ability to survive extreme temperatures, but its capacity to maintain its critical properties—such as chemical inertness and low friction—across that entire operational window. This makes it a uniquely reliable choice for demanding environments.

Understanding PTFE's Thermal Performance

Many materials can withstand a wide temperature range, but PTFE stands apart by retaining its most valuable characteristics at both ends of the spectrum. This consistent performance is the primary reason it is specified for critical applications.

The Upper Temperature Limit: Stability at 500°F (260°C)

At its upper limit of 500°F (260°C), PTFE maintains excellent structural and chemical integrity. Unlike most thermoplastics, it does not have a true melting point; it simply softens, retaining its shape without significant degradation.

This high-heat tolerance makes it ideal for components like high-temperature seals, gaskets, and instrumentation fittings that operate in engines, industrial ovens, or chemical processing equipment.

The Lower Temperature Limit: Resilience in Cryogenics

As temperatures drop, many plastics and elastomers become hard and brittle, leading to fractures and seal failure. PTFE, however, remains flexible and functional even at cryogenic temperatures as low as -328°F (-200°C).

This lack of embrittlement makes it an essential material for applications involving liquefied gases like nitrogen or oxygen, where other materials would become dangerously unreliable.

How PTFE Compares to Other Materials

PTFE's thermal range far exceeds that of most common polymers. For instance, plastics like Polypropylene and ABS begin to deform at much lower temperatures.

More importantly, it vastly outperforms most elastomers (rubbers). While specialized rubber compounds exist, very few can cover the same combined high-heat and cryogenic range as PTFE, which does so while also offering superior chemical resistance.

Understanding the Trade-offs and Key Considerations

While its thermal stability is impressive, understanding PTFE's behavior under load and over time is critical for successful engineering design. Its properties are not static, and temperature extremes can influence its mechanical performance.

Thermal Expansion

PTFE has a high coefficient of thermal expansion. This means it expands and contracts more than metals and many other plastics when the temperature changes. Designs must incorporate proper tolerances to prevent parts from seizing or seals from failing due to this dimensional change.

Creep or "Cold Flow"

Under sustained compressive load, PTFE can slowly deform over time, a phenomenon known as creep or cold flow. This effect is more pronounced at higher temperatures. For high-load static seals, this must be accounted for in the design to prevent a loss of sealing pressure.

The Role of Fillers

Different grades of PTFE exist to mitigate some of these trade-offs. Adding fillers like glass fiber, carbon, or bronze can significantly improve mechanical properties. For example, glass-filled PTFE exhibits higher compressive strength and reduced creep, making it better suited for high-load applications near the material's upper temperature limit.

Making the Right Choice for Your Application

Selecting the right material requires balancing thermal needs with mechanical demands. Use these guidelines to determine if PTFE is the optimal choice for your project.

- If your primary focus is high-temperature stability (up to 500°F / 260°C): PTFE is an excellent choice, but consider a filled grade if your application also involves high mechanical loads or requires minimal deformation.

- If your primary focus is cryogenic performance (down to -328°F / -200°C): Virgin PTFE is a premier option, as it retains its flexibility and sealing capability where most other polymers become brittle and fail.

- If your application involves high pressure or tight tolerances: You must design specifically for PTFE's high thermal expansion and its potential for creep, especially when operating at elevated temperatures.

By understanding both the strengths and limitations of PTFE, you can confidently engineer a solution that leverages its remarkable thermal resilience.

Summary Table:

| Property | Value |

|---|---|

| Continuous Service Temperature Range | -328°F to 500°F (-200°C to 260°C) |

| Key Property at High Temperatures | Maintains structural integrity and chemical inertness |

| Key Property at Low Temperatures | Remains flexible, resists embrittlement |

| Key Consideration | High thermal expansion and potential for creep under load |

Need a reliable PTFE component for extreme temperatures?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—that excel in the most demanding thermal environments, from cryogenics to high-heat industrial processes. We serve the semiconductor, medical, laboratory, and specialized industrial sectors with precision production, from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can ensure reliability and performance for your specific application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability