In regulated industries like food, beverage, and pharmaceuticals, material selection is never just about performance—it's about safety and purity. Expanded Polytetrafluoroethylene (ePTFE) sheets are a preferred material because their unique combination of properties directly addresses this core need: they are chemically inert, non-toxic, and meet stringent regulatory standards for food and drug contact, ensuring the final product remains uncontaminated.

The fundamental value of ePTFE in these sensitive sectors is its ability to be a perfect barrier. It seals equipment effectively without reacting with, leaching into, or adsorbing the product, thereby guaranteeing the integrity and purity of the process from start to finish.

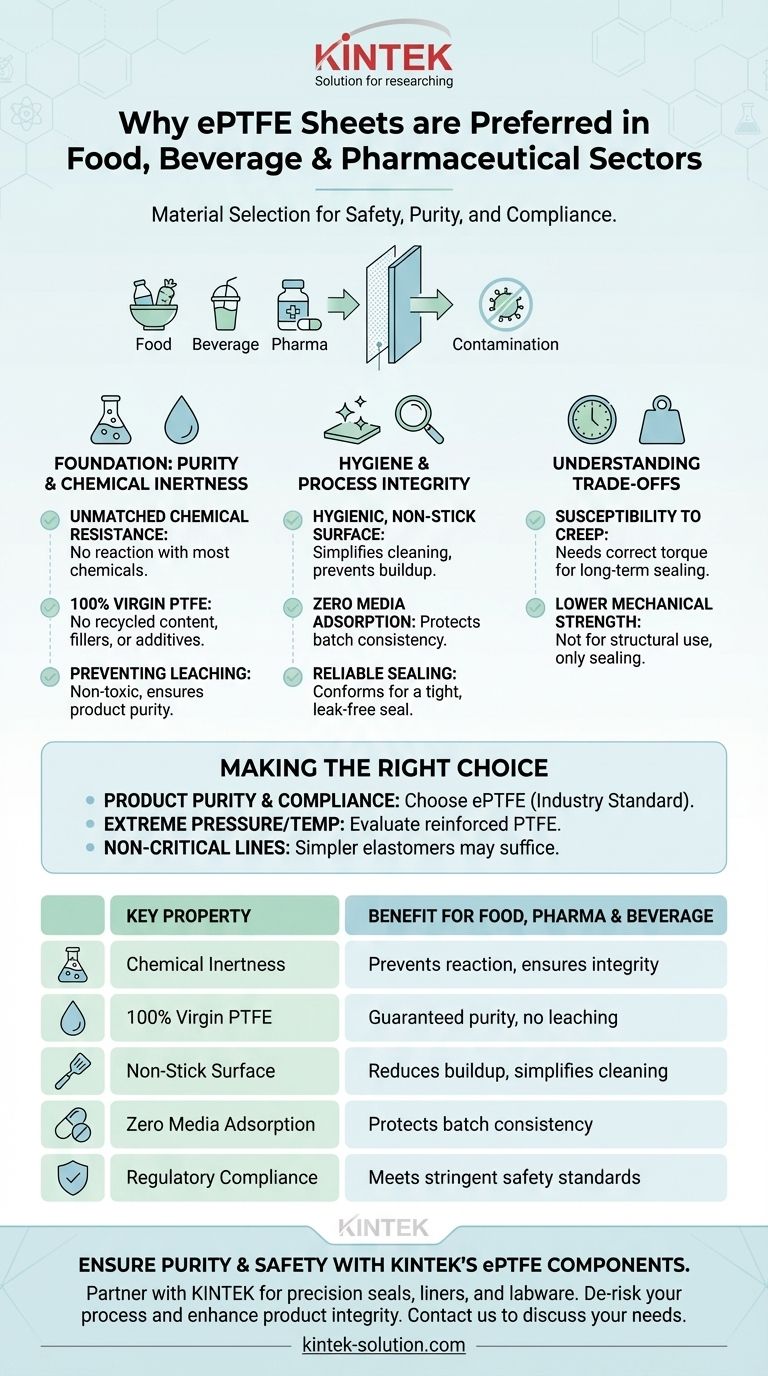

The Foundation: Purity and Chemical Inertness

The primary reason for ePTFE's dominance is its intrinsic nature. It is engineered to be a non-participant in chemical processes, which is the highest priority when producing consumables and medicine.

Unmatched Chemical Resistance

ePTFE is derived from PTFE, one of the most chemically inert polymers known. This means it does not react with the vast majority of industrial chemicals, solvents, acids, or bases.

This property is critical because it ensures the sealing material itself won't degrade and introduce impurities into the product stream, regardless of the ingredients being processed.

Guaranteed Purity with 100% Virgin PTFE

ePTFE sheets for these applications are made from 100% virgin PTFE. This is a crucial distinction.

Using virgin material means there are no recycled content, fillers, or additives that could potentially leach out over time. It provides a certifiable baseline of purity.

Preventing Leaching and Contamination

The combination of inertness and purity means ePTFE does not leach chemicals into the media it contains. This prevents contamination and ensures the product's formulation remains exactly as intended.

It also means the material is non-toxic, a fundamental requirement for any surface that comes into contact with food or pharmaceuticals.

Ensuring Hygiene and Process Integrity

Beyond its chemical makeup, the physical structure of ePTFE contributes directly to maintaining a clean and controlled manufacturing environment.

Hygienic, Non-Stick Surfaces

ePTFE has an extremely low-friction, non-stick surface. In a processing environment, this prevents product residue or microorganisms from building up on the gasket or seal.

This property simplifies cleaning and sterilization protocols, reducing the risk of biofilm formation and cross-contamination between batches.

Zero Media Adsorption

Unlike some other materials that can act like a sponge, ePTFE does not adsorb (absorb onto its surface) the media it is sealing.

This is vital in pharmaceutical manufacturing, where active ingredients are highly potent and precisely dosed. A material that traps even a small amount of the product could compromise the entire batch's quality and consistency.

Reliable Sealing Performance

While its chemical and hygienic properties are paramount, ePTFE is also an excellent gasket material. It conforms to irregular surfaces to create a tight, long-lasting seal.

This physical function prevents leaks, which are a two-way contamination risk: they can let environmental contaminants in or allow valuable, sterile product to escape.

Understanding the Trade-offs

No material is perfect for every scenario. A true technical evaluation requires acknowledging the limitations of ePTFE to ensure it is applied correctly.

Susceptibility to Creep (Cold Flow)

PTFE is a relatively soft material and can be susceptible to creep, also known as cold flow. This is a slow deformation that can occur over time when the material is under constant pressure, especially at elevated temperatures.

Engineers must account for this by using correct bolt torque specifications and joint designs to maintain a reliable long-term seal.

Lower Mechanical Strength

Compared to metals or harder plastics, ePTFE has lower compressive and tensile strength. It is not a structural material.

Its role is strictly for sealing and gasketing, and it would not be suitable for applications requiring high mechanical rigidity or load-bearing capability.

Making the Right Choice for Your Goal

When selecting a sealing material, your primary objective should guide your decision.

- If your primary focus is product purity and regulatory compliance: ePTFE is the industry standard and safest choice, as its inertness and non-toxic nature are unmatched for food and pharma applications.

- If your primary focus is extreme pressure and temperature: You may need to evaluate mechanically stronger materials or reinforced PTFE gaskets, but you must verify their chemical compatibility and compliance.

- If your primary focus is sealing non-critical utility lines (e.g., plant water): Simpler, less expensive elastomers may be sufficient, but they should never be used for direct or indirect product contact.

Ultimately, choosing ePTFE is a strategic decision to de-risk your process and guarantee the integrity of your final product.

Summary Table:

| Key Property | Benefit for Food, Pharma & Beverage |

|---|---|

| Chemical Inertness | Prevents reaction with ingredients, ensuring product integrity |

| 100% Virgin PTFE | Guaranteed purity with no risk of leaching or contamination |

| Non-Stick Surface | Reduces residue buildup, simplifies cleaning and sterilization |

| Zero Media Adsorption | Protects batch consistency in pharmaceutical dosing |

| Regulatory Compliance | Meets stringent standards for food and drug contact safety |

Ensure the purity and safety of your products with KINTEK's high-performance ePTFE components.

At KINTEK, we specialize in manufacturing precision PTFE and ePTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our use of 100% virgin PTFE guarantees material purity, while our custom fabrication services—from prototypes to high-volume orders—ensure a perfect fit for your specific application.

Partner with us to:

- De-risk your manufacturing process with chemically inert, non-toxic materials.

- Meet strict regulatory requirements for food, beverage, and pharmaceutical applications.

- Enhance product integrity with reliable sealing solutions that prevent contamination.

Contact us today to discuss your project needs and discover how our expertise can support your quality and compliance goals.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What makes PTFE seals suitable for high-temperature applications? Unmatched Thermal & Chemical Stability

- What is the Ring and Energizer PTFE seal design? A Guide to Low-Friction Bi-Directional Sealing

- What are the benefits of Teflon bellow mechanical seals for manufacturers and suppliers? Unlock New Market Opportunities

- What are the challenges and solutions for PTFE washers regarding mechanical strength? Overcome Creep with Reinforced PTFE

- What are the benefits of PTFE bushes over plastic bushings? Superior Performance for Harsh Environments

- What are the main benefits of Teflon packing? Achieve Superior Sealing for Demanding Applications

- What are the benefits of using PTFE lined check valves in water pump systems? Boost Reliability & Cut Costs

- What industries commonly use Teflon CNC machined parts? Critical Solutions for Aerospace, Medical & More