To be direct, Teflon CNC machined parts are critical components in the aerospace, medical, food processing, electronics, chemical, and automotive industries. These sectors rely on Teflon's unique combination of properties to solve complex engineering challenges where other materials would fail.

The widespread use of machined Teflon is not arbitrary. It is a deliberate choice driven by the material's unparalleled chemical inertness, extremely low friction, and excellent performance as an electrical and thermal insulator, making it a go-to solution for the most demanding applications.

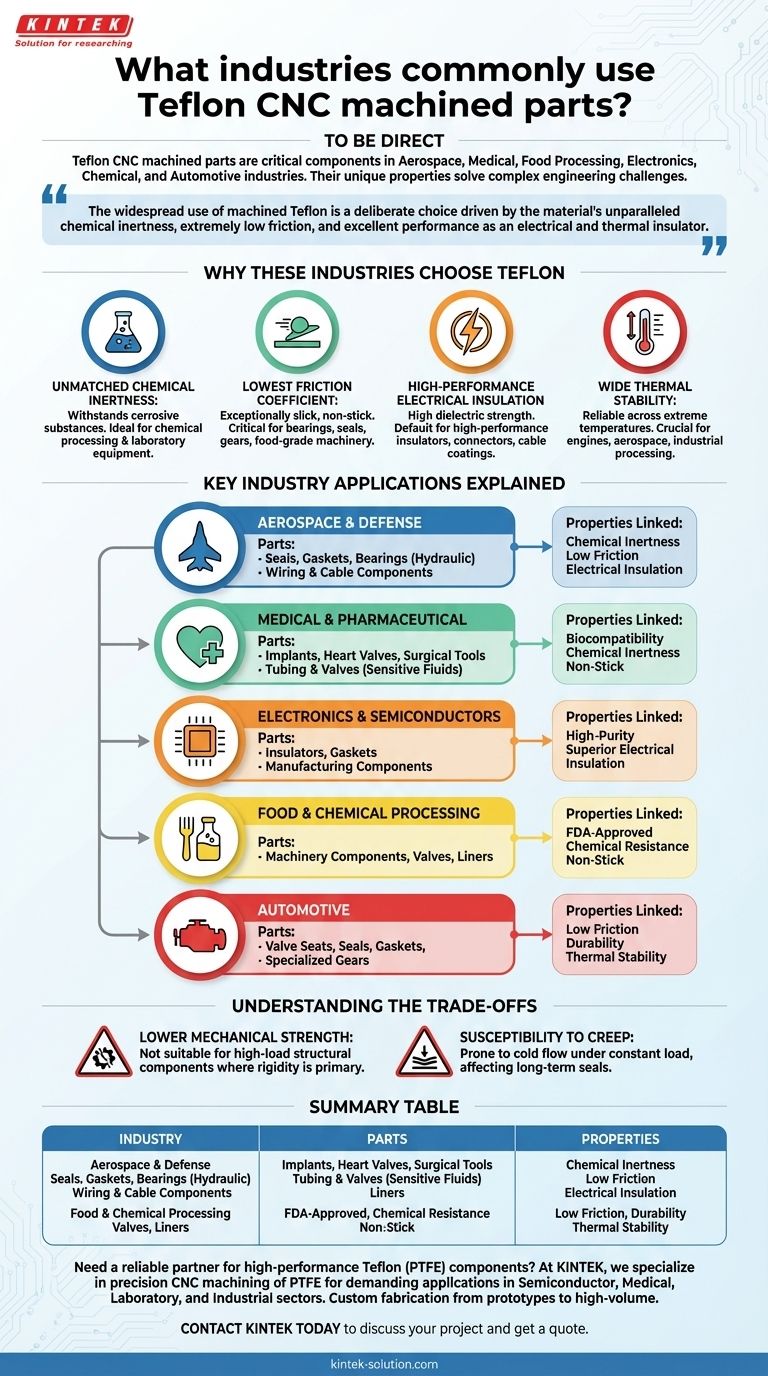

Why These Industries Choose Teflon

The selection of a material for a critical component is a function of its inherent properties. Teflon, or Polytetrafluoroethylene (PTFE), possesses a unique combination of characteristics that make it invaluable.

Unmatched Chemical Inertness

Teflon is famously non-reactive. It can withstand exposure to nearly all industrial chemicals and solvents, making it essential for equipment that handles corrosive substances.

This property is the primary reason for its heavy use in chemical processing and laboratory equipment.

The Lowest Friction Coefficient

Teflon has one of the lowest coefficients of friction of any solid material, creating an exceptionally slick, non-stick surface.

This is critical for components like bearings, seals, and gears where minimizing resistance and wear is paramount. It also makes Teflon ideal for food-grade machinery where cleanability is essential.

High-Performance Electrical Insulation

Teflon is an excellent electrical insulator with a very high dielectric strength. It maintains its insulating properties across a wide range of frequencies and temperatures.

This makes it a default choice for high-performance insulators, connectors, and cable coatings in the aerospace and electronics industries.

Wide Thermal Stability

Teflon performs reliably across a very broad temperature range. It can handle extreme cold and significant heat without degrading its core properties.

This thermal resilience is crucial for components used in engines, aerospace applications, and industrial processing environments.

Key Industry Applications Explained

Understanding the properties explains the "why." Now let's examine the specific "what"—the parts being made for each sector.

Aerospace & Defense

In aerospace, reliability is non-negotiable. Teflon is used for seals, gaskets, and bearings in hydraulic systems due to its low friction and chemical resistance. Its properties as a superior electrical insulator also make it vital for wiring and cable components.

Medical & Pharmaceutical

Teflon is highly biocompatible, meaning the human body does not react to it. This allows for its use in implants, heart valves, and surgical tools. Its inertness and non-stick surface are also perfect for tubing and valves that handle sensitive fluids.

Electronics & Semiconductors

The semiconductor industry demands extreme purity and performance. Teflon's chemical inertness and superior insulating properties make it essential for insulators, gaskets, and components used in manufacturing equipment where contamination cannot be tolerated.

Food & Chemical Processing

Due to its non-reactive nature, Teflon is FDA-approved for food contact. It is machined into machinery components, valves, and liners for equipment that processes food or aggressive chemicals, ensuring no material leaches into the final product.

Automotive

In the automotive sector, Teflon is machined for parts that require low friction and durability. Common applications include valve seats, seals, gaskets, and specialized gears that improve efficiency and reduce wear in engine and transmission systems.

Understanding the Trade-offs

While Teflon is a high-performance material, it is not a universal solution. An expert understanding requires acknowledging its limitations.

Lower Mechanical Strength

Compared to metals or high-strength engineering plastics like PEEK, Teflon is a relatively soft material. It is generally not suitable for high-load structural components where rigidity and tensile strength are the primary requirements.

Susceptibility to Creep

Under a constant, sustained load, Teflon can be prone to "creep" or cold flow, meaning it may slowly deform over time. This must be accounted for in the design of parts like seals and gaskets that are under constant pressure.

Making the Right Choice for Your Goal

Selecting Teflon should be a deliberate decision based on its unique strengths.

- If your primary focus is chemical resistance or biocompatibility: Teflon is one of the best choices available for parts exposed to corrosive chemicals or used in medical applications.

- If your primary focus is low friction and a non-stick surface: Teflon is the industry standard for creating bearings, seals, and surfaces that require minimal friction and easy cleaning.

- If your primary focus is high-performance electrical insulation: Teflon is a superior material for insulators in demanding electronic and aerospace contexts, especially at high frequencies.

- If your primary focus is high mechanical load or structural rigidity: You should evaluate other materials, as this is Teflon's primary trade-off.

Teflon is a specialty polymer chosen to solve problems that commodity materials simply cannot address.

Summary Table:

| Industry | Primary Use of Teflon Parts | Key Teflon Property Utilized |

|---|---|---|

| Aerospace & Defense | Seals, gaskets, bearings, electrical insulators | Chemical inertness, low friction, electrical insulation |

| Medical & Pharmaceutical | Implants, surgical tools, tubing, valves | Biocompatibility, chemical inertness, non-stick surface |

| Electronics & Semiconductors | Insulators, gaskets, manufacturing components | High-purity, superior electrical insulation |

| Food & Chemical Processing | Machinery components, valves, liners | FDA-approved, chemical resistance, non-stick |

| Automotive | Valve seats, seals, gaskets, specialized gears | Low friction, durability, thermal stability |

Need a reliable partner for high-performance Teflon (PTFE) components?

At KINTEK, we specialize in precision CNC machining of PTFE for the most demanding applications. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your components meet the highest standards for chemical resistance, low friction, and electrical insulation.

We offer custom fabrication from prototypes to high-volume orders, prioritizing the precision your critical applications require.

Contact KINTEK today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech