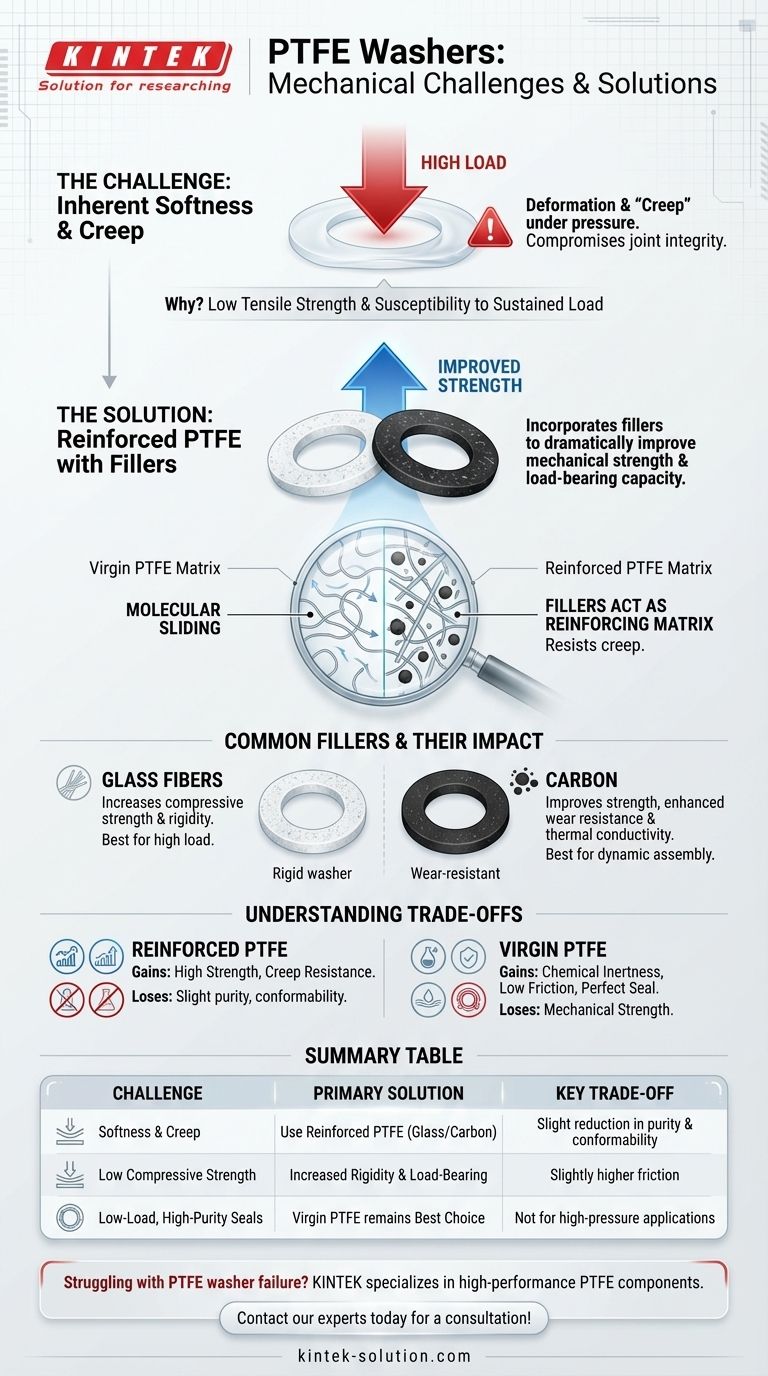

The primary mechanical challenge with PTFE washers is their inherent softness, which can lead to deformation or "creep" under high compressive loads. Because PTFE is significantly less rigid than metal, it can be squeezed out of shape, compromising the integrity of a joint. The most effective solution is to use reinforced PTFE washers that incorporate fillers like glass or carbon to dramatically improve mechanical strength and load-bearing capacity.

While virgin PTFE is prized for its exceptional chemical resistance and low friction, its mechanical softness is a critical limitation. The solution lies in choosing a filled or reinforced grade of PTFE, which enhances strength at the cost of slight trade-offs in other properties.

The Dual Nature of PTFE Properties

To understand the solution, we must first appreciate the inherent characteristics of Polytetrafluoroethylene (PTFE) as a material. Its greatest strengths in some applications are its primary weaknesses in others.

### The Advantage of Extreme Chemical Inertness

PTFE is renowned for its resistance to nearly all chemicals and solvents. This makes it an ideal choice for washers and seals in corrosive or otherwise harsh environments, from food processing to aerospace engineering.

### Unmatched Low-Friction Performance

With one of the lowest coefficients of friction of any solid material, PTFE ensures that assemblies can move or be adjusted with minimal force. This "slipperiness" reduces wear and energy loss in dynamic applications.

### The Challenge: Mechanical Weakness

The core issue is that PTFE has a relatively low tensile strength (280-350 kg/cm²) compared to metals. More importantly, it is susceptible to creep—a slow, permanent deformation that occurs when the material is subjected to a sustained load, even one below its yield strength.

The Solution: Reinforcing PTFE with Fillers

To overcome its mechanical softness, PTFE is often blended with other materials. These fillers create a composite material that retains most of PTFE's benefits while significantly improving its physical strength.

### How Fillers Increase Strength

Fillers act as a reinforcing matrix within the softer PTFE polymer. They disrupt the ability of the PTFE molecules to slide past one another under pressure, which directly increases the material's resistance to creep and deformation.

### Common Fillers and Their Impact

The most common fillers are glass fibers and carbon. Glass-filled PTFE offers a substantial increase in compressive strength and rigidity. Carbon-filled PTFE also improves strength while adding enhanced wear resistance and thermal conductivity.

Understanding the Trade-offs

Using reinforced PTFE is not without its compromises. Choosing the right material requires understanding what is gained and what is potentially lost.

### Sacrificing Absolute Purity

The primary trade-off is purity. While still highly resistant, a filled PTFE is no longer 100% chemically inert. The filler material itself may not have the same universal chemical resistance as virgin PTFE, which can be a factor in highly specific applications.

### Altering Frictional and Sealing Properties

Fillers can slightly increase the coefficient of friction compared to virgin PTFE. More importantly, the increased hardness can reduce the washer's ability to conform and create a perfect seal in very low-pressure applications.

### When Unfilled PTFE is the Better Choice

For applications where the load is minimal and the primary requirement is a perfect seal, absolute chemical purity, or the lowest possible friction, virgin (unfilled) PTFE remains the superior choice.

Making the Right Choice for Your Application

Your final decision must be guided by the primary demand of your specific application.

- If your primary focus is load-bearing and mechanical stability: Choose a glass or carbon-filled PTFE washer to prevent creep and deformation under high pressure.

- If your primary focus is creating a perfect seal in a low-load, corrosive environment: Use a virgin (unfilled) PTFE washer for its superior conformity and chemical purity.

- If your primary focus is durability and wear resistance in a dynamic assembly: A carbon-filled PTFE washer often provides the best balance of strength, low friction, and longevity.

Ultimately, selecting the correct PTFE washer is about matching the material's specific formulation to the mechanical demands of your design.

Summary Table:

| Challenge | Primary Solution | Key Trade-off |

|---|---|---|

| Softness & Creep (Deformation under load) | Use Reinforced PTFE (e.g., glass/carbon filled) | Slight reduction in chemical purity & conformability |

| Low Compressive Strength | Increased rigidity and load-bearing capacity | Slightly higher coefficient of friction |

| Suitable for low-load, high-purity seals | Virgin PTFE remains the best choice | Not suitable for high-pressure applications |

Struggling with PTFE washer failure under pressure? KINTEK specializes in manufacturing high-performance PTFE components, including custom washers for the semiconductor, medical, laboratory, and industrial sectors. We offer both virgin and reinforced PTFE grades to perfectly match your application's demand for mechanical strength, chemical resistance, or low friction. From prototypes to high-volume orders, our precision production ensures reliability.

Let us help you select the ideal material. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications