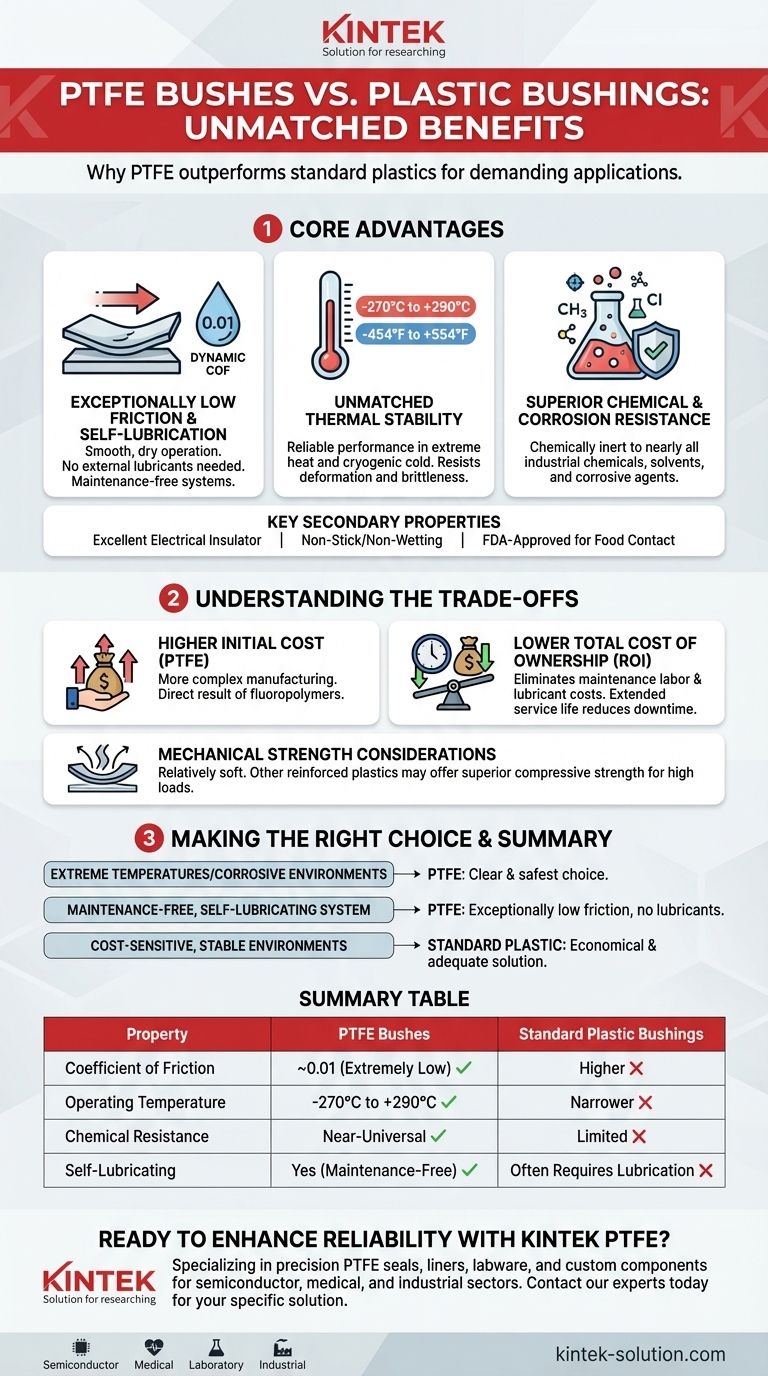

In short, PTFE bushes outperform most standard plastic bushings in three critical areas: a significantly lower coefficient of friction, a much wider operating temperature range, and near-universal chemical resistance. This unique combination makes them self-lubricating and exceptionally durable in harsh environments where other plastics would degrade or fail.

The decision to use PTFE over other plastics is not just about performance, but about operational reliability. While other plastics may offer higher mechanical strength, PTFE provides an unmatched combination of self-lubrication, chemical inertness, and thermal stability, making it the definitive choice for maintenance-free operation in extreme conditions.

The Core Advantages of PTFE Explained

To understand why PTFE is often specified for demanding applications, we need to examine its fundamental material properties. These characteristics work together to deliver performance that commodity plastics cannot match.

Exceptionally Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material, with a dynamic value as low as 0.01.

This extremely slick surface allows for smooth, efficient movement with minimal resistance. More importantly, it means PTFE bushings can operate dry, without any external grease or oil. This self-lubricating property is the key to creating maintenance-free systems.

Unmatched Thermal Stability

PTFE exhibits remarkable stability across a vast temperature range, performing reliably from -270°C to +290°C (-454°F to +554°F).

Most conventional plastics have a much narrower operating window and can become brittle at low temperatures or deform at high temperatures. PTFE's resilience makes it suitable for everything from cryogenic applications to high-temperature industrial processes.

Superior Chemical and Corrosion Resistance

PTFE is chemically inert to nearly all industrial chemicals, solvents, and corrosive agents.

This property is critical in applications involving aggressive substances, such as in chemical processing, medical devices, or laboratory equipment. Where other plastics would corrode or dissolve, PTFE remains unaffected, ensuring the longevity and integrity of the component.

Key Secondary Properties

Beyond these primary benefits, PTFE offers several other valuable characteristics.

It is an excellent electrical insulator with a very low dielectric constant. Its surface is also non-stick, non-wetting, and resistant to radiation, and it is FDA-approved for direct contact with food, making it highly versatile.

Understanding the Trade-offs

No material is perfect for every situation. Being an effective advisor means acknowledging the limitations and cost implications of choosing a high-performance material like PTFE.

The Initial Cost Factor

PTFE bushings are generally more expensive than bushings made from common plastics like nylon or acetal.

This higher upfront cost is a direct result of the more complex manufacturing process for fluoropolymers.

The Return on Investment: Total Cost of Ownership

The initial investment in PTFE is often justified by a lower total cost of ownership.

Because PTFE bushings are self-lubricating, they eliminate costs associated with maintenance labor and lubricants. Their extended service life also reduces downtime and replacement frequency, providing significant long-term savings in critical applications.

Mechanical Strength Considerations

While PTFE's combination of properties is unique, it is a relatively soft material.

For applications with extremely high mechanical loads or severe abrasive wear, other specialized or reinforced engineering plastics might offer superior compressive strength. The choice always depends on the primary demand of the application.

Making the Right Choice for Your Goal

Selecting the correct bushing material requires matching the material's strengths to the specific demands of your application.

- If your primary focus is operating in extreme temperatures or corrosive environments: PTFE's chemical inertness and wide thermal range make it the clear and safest choice.

- If your primary focus is creating a maintenance-free, self-lubricating system: PTFE's exceptionally low friction allows for smooth, dry operation, eliminating the complexity and cost of external lubricants.

- If your primary focus is cost-sensitive and the application is in a stable, non-demanding environment: A standard plastic bushing may be a more economical and perfectly adequate solution.

Ultimately, selecting PTFE is an investment in long-term reliability for applications where performance cannot be compromised.

Summary Table:

| Property | PTFE Bushes | Standard Plastic Bushings |

|---|---|---|

| Coefficient of Friction | ~0.01 (Extremely Low) | Higher |

| Operating Temperature Range | -270°C to +290°C | Narrower |

| Chemical Resistance | Near-Universal | Limited |

| Self-Lubricating | Yes (Maintenance-Free) | Often Requires Lubrication |

| Initial Cost | Higher | Lower |

| Long-Term Cost of Ownership | Lower (Less Maintenance/Downtime) | Can Be Higher |

Ready to enhance your equipment's reliability with high-performance PTFE components?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the exact solution for your demanding application, from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can deliver long-term value and performance for your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments