The primary maintenance advantage of PTFE compensators lies in their unique material properties, which inherently prevent the most common causes of failure and intervention. The extremely low coefficient of friction and non-stick surface of PTFE stop process media from building up, scaling, or sticking, which drastically reduces the need for cleaning and ensures consistent system performance.

The core takeaway is that PTFE compensators don't just simplify maintenance—they are designed to eliminate it. Their inherent material characteristics prevent common issues like clogging and contamination, leading directly to higher operational reliability and less system downtime.

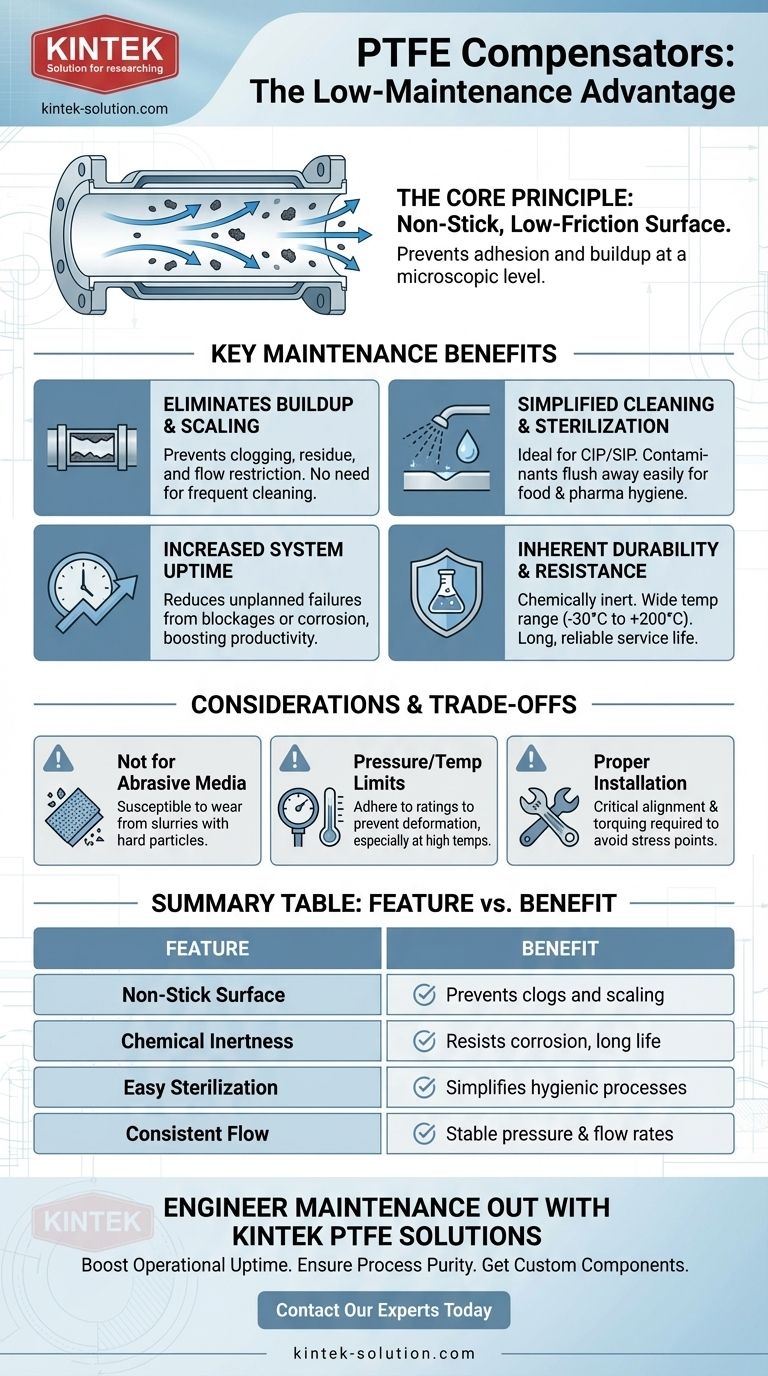

The Core Principle: How Material Science Reduces Maintenance

The maintenance benefits of PTFE are not an added feature; they are a direct result of its fundamental molecular structure. Understanding this connection is key to appreciating its value in a demanding operational environment.

The Lowest Coefficient of Friction

Polytetrafluoroethylene (PTFE) possesses the lowest coefficient of friction of any known solid material. This means that other substances slide off its surface with extreme ease.

This "non-stick" quality is the foundation of its low-maintenance profile. It actively repels the adhesion of other materials at a microscopic level.

Eliminating Deposit and Scale Buildup

In practical terms, this low-friction surface prevents the buildup of deposits, residue, or scaling inside the pipeline. Media flows through cleanly without leaving behind layers that can harden and restrict flow.

This eliminates the need for frequent mechanical or chemical cleaning that is often required for compensators made from other materials, saving significant time and labor.

Simplified Cleaning and Sterilization

For industries with strict hygiene standards, such as food, beverage, and pharmaceuticals, PTFE's non-adhesive surface is a critical advantage.

It ensures that Clean-in-Place (CIP) and Sterilization-in-Place (SIP) processes are highly effective and efficient. Contaminants are easily flushed away, ensuring product purity and reducing the risk of batch contamination.

The Impact on System Uptime and Reliability

Reducing planned maintenance is only part of the equation. The true value of PTFE compensators emerges in their ability to prevent unplanned failures and enhance overall system stability.

Maintaining Consistent Flow

By preventing internal buildup, PTFE compensators ensure that the pipeline's internal diameter remains constant. This leads to predictable and stable flow rates and pressure levels.

This reliability is crucial for sensitive processes where fluctuations can impact product quality or safety. The system performs as designed for longer periods without degradation.

Reducing Unscheduled Downtime

The most common reasons for compensator failure or emergency maintenance are blockages or corrosion. PTFE's properties directly counter both of these threats.

Its resistance to buildup prevents clogs, while its chemical inertness prevents corrosion. This translates directly to fewer unexpected shutdowns and higher plant productivity.

Inherent Durability and Resistance

Beyond its surface properties, PTFE is a highly durable material. It operates across a wide temperature range (typically -30°C to +200°C) and has excellent flexural strength.

Its weatherability and water resistance ensure it does not degrade from environmental factors, providing a long and reliable service life with minimal need for replacement.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its operational limits to ensure its advantages are fully realized.

Not Ideal for Abrasive Media

The same non-stick surface that repels buildup can be susceptible to physical wear from highly abrasive media, such as slurries containing hard, sharp particles. In these specific cases, a rubber or metallic joint may be more appropriate.

Adherence to Pressure/Temperature Limits

While PTFE has a wide operating temperature range, its mechanical strength can decrease at the upper limits, especially under high pressure. Operating within the manufacturer's specified pressure and temperature ratings is critical to prevent deformation or premature failure.

The Importance of Correct Installation

No compensator can overcome the stress of improper installation. Misalignment, improper anchoring, or over-torquing of flanges can create stress points that lead to failure, negating the inherent material benefits of PTFE.

Making the Right Choice for Your Application

Selecting the right compensator is about aligning its material strengths with your primary operational goals.

- If your primary focus is hygiene and sanitation (e.g., food, pharma): PTFE's non-stick, easily cleanable surface is your best defense against contamination and ensures process purity.

- If your primary focus is process stability and uptime (e.g., chemical processing): PTFE's resistance to scaling and corrosion maintains consistent flow and dramatically reduces maintenance-related shutdowns.

- If your primary focus is managing aggressive or corrosive media: PTFE's chemical inertness provides a long, reliable service life where other materials would quickly degrade and require costly replacement.

Ultimately, selecting PTFE is a strategic decision to engineer maintenance requirements out of your system from the start.

Summary Table:

| Maintenance Advantage | Key Benefit |

|---|---|

| Non-Stick Surface | Prevents buildup of process media, eliminating clogs and scaling. |

| Chemical Inertness | Resists corrosion from aggressive chemicals, ensuring long service life. |

| Easy Sterilization | Simplifies CIP/SIP processes for food, pharma, and other hygienic industries. |

| Consistent Flow | Maintains internal diameter for stable pressure and flow rates over time. |

Engineer maintenance out of your system with KINTEK PTFE components.

Are you facing challenges with frequent downtime, costly cleaning cycles, or contamination in your semiconductor, medical, or laboratory processes? KINTECH specializes in manufacturing high-precision PTFE seals, liners, labware, and custom components that leverage the inherent low-maintenance properties of PTFE.

We can help you:

- Boost Operational Uptime: Drastically reduce both planned and unplanned maintenance by preventing the root causes of failure.

- Ensure Process Purity: Our non-stick, chemically inert PTFE components are ideal for hygienic and sensitive applications.

- Get a Custom Solution: From initial prototypes to high-volume production, we fabricate components to your exact specifications.

Ready to enhance your system's reliability? Contact our experts today to discuss how our PTFE solutions can solve your specific maintenance challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the benefits of PTFE butterfly valves in industrial applications? Enhance Safety, Purity & Efficiency

- What are the benefits of 55% Bronze + 5% MoS2-filled PTFE bushings? Achieve Superior Performance in High-Load Applications

- What makes PTFE chemically resistant? The Power of Fluorine's Protective Shield

- What are the main advantages of PTFE mechanical seals? Superior Chemical & Temperature Resistance

- What new technologies are being applied to PTFE O-ring seals? Enhance Performance with Nanomaterials & 3D Printing

- How are custom PTFE parts used in the automotive sector? Enhance Vehicle Performance & Durability

- Why are PTFE oil seals considered a superior choice for many applications? Unlock Reliability in Extreme Conditions

- What advantage does the low friction property of PTFE oil seals provide? Extend Equipment Life & Save Energy