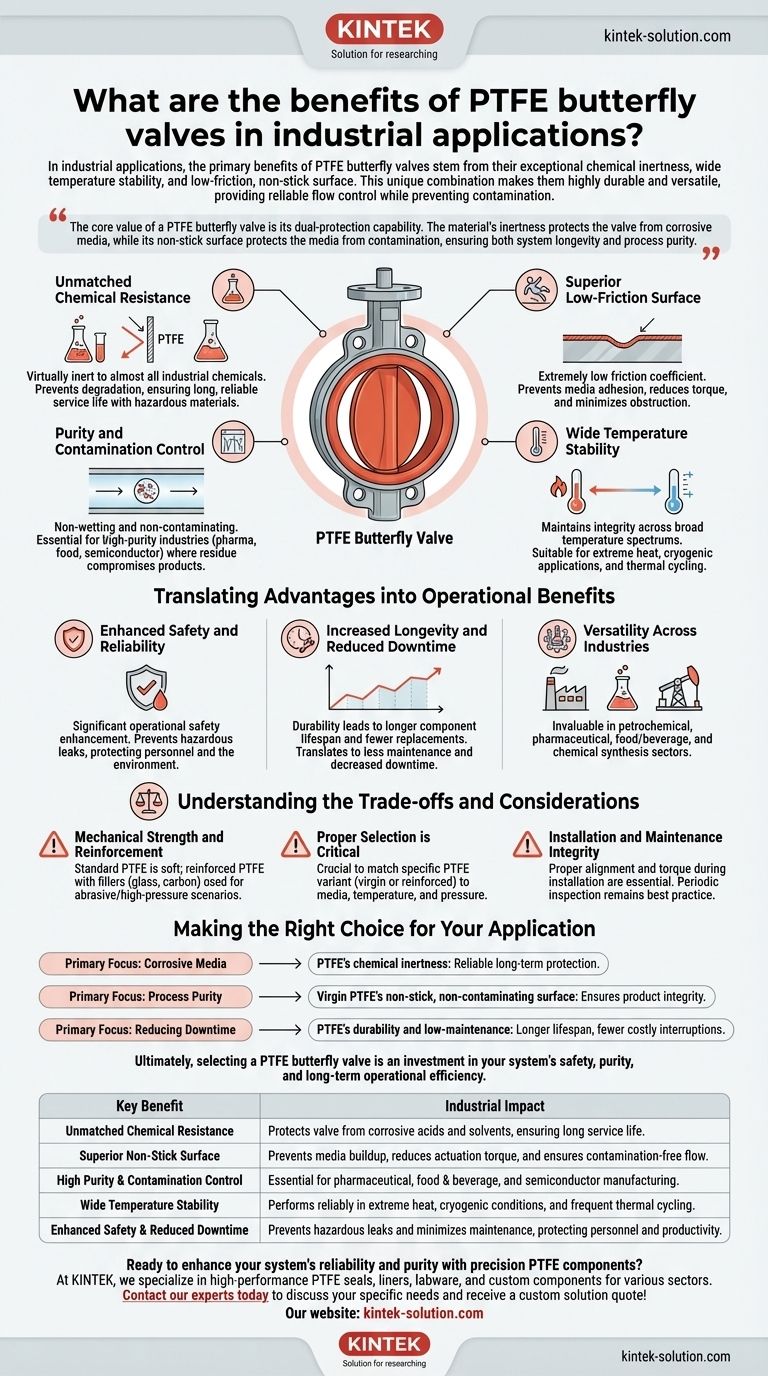

In industrial applications, the primary benefits of PTFE butterfly valves stem from their exceptional chemical inertness, wide temperature stability, and low-friction, non-stick surface. This unique combination makes them highly durable and versatile, providing reliable flow control while preventing contamination in a vast range of demanding processes.

The core value of a PTFE butterfly valve is its dual-protection capability. The material’s inertness protects the valve from corrosive media, while its non-stick surface protects the media from contamination, ensuring both system longevity and process purity.

The Core Advantages of PTFE in Valve Design

Polytetrafluoroethylene (PTFE) is not just a coating; it's a high-performance polymer that fundamentally enhances the valve's function. Its distinct properties solve several critical industrial challenges.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, solvents, and corrosive substances. This chemical resistance prevents the valve components from degrading, ensuring a long and reliable service life even when handling hazardous materials.

Superior Low-Friction Surface

The material has an extremely low coefficient of friction, giving it a non-stick surface. This characteristic is critical for preventing media from adhering to the valve's internal parts, which reduces the torque needed for actuation and minimizes material buildup that could obstruct flow.

Purity and Contamination Control

Because nothing sticks to it, PTFE is ideal for applications where purity is paramount. This non-wetting and non-contaminating quality is essential in industries like pharmaceuticals, food processing, and semiconductor manufacturing, where even trace amounts of residue can compromise a product batch.

Wide Temperature Stability

PTFE components maintain their integrity and performance across a broad spectrum of temperatures. This thermal stability makes them suitable for processes that involve extreme heat, cryogenic applications, or frequent thermal cycling without compromising sealing capabilities.

Translating Advantages into Operational Benefits

These material properties deliver tangible benefits that impact safety, efficiency, and an organization's bottom line.

Enhanced Safety and Reliability

By resisting chemical attack and providing exceptional sealing, PTFE-lined butterfly valves significantly enhance operational safety. They prevent the leakage of hazardous materials, protecting personnel and the environment from exposure.

Increased Longevity and Reduced Downtime

A valve that withstands its environment lasts longer. The durability of PTFE leads to a longer component lifespan and a reduced need for replacements, which directly translates to less maintenance, minimized waste, and decreased industrial downtime.

Versatility Across Industries

The combination of these benefits makes PTFE butterfly valves a go-to solution in numerous sectors. They are invaluable in petrochemical plants, pharmaceutical research, food and beverage production, and chemical synthesis, where reliability and purity cannot be compromised.

Understanding the Trade-offs and Considerations

While highly effective, PTFE valves are not a universal solution. Understanding their limitations is key to successful implementation.

Mechanical Strength and Reinforcement

Standard PTFE is a relatively soft material and can be susceptible to wear in highly abrasive applications or deformation under high pressure. For these demanding scenarios, reinforced PTFE, which includes fillers like glass fiber, carbon, or bronze, is used to enhance durability and mechanical strength.

Proper Selection is Critical

The term "PTFE" can describe different formulations. Using virgin PTFE is crucial for high-purity applications, while a reinforced variant might be necessary for high-pressure systems. Matching the specific valve type to the application's media, temperature, and pressure is essential for success.

Installation and Maintenance Integrity

Even the most advanced valve will fail if installed improperly. Proper alignment and torque during installation are critical to ensure a perfect seal. While low-maintenance, periodic inspection remains a best practice to guarantee long-term system efficiency.

Making the Right Choice for Your Application

Selecting the correct valve hinges on your primary operational goal.

- If your primary focus is handling corrosive media: PTFE's chemical inertness offers the most reliable long-term solution to prevent valve degradation and hazardous leaks.

- If your primary focus is process purity: The non-stick, non-contaminating surface of virgin PTFE is essential for preventing material buildup and ensuring product integrity.

- If your primary focus is reducing operational downtime: PTFE's durability and low-maintenance characteristics lead to a longer component lifespan and fewer costly interruptions.

Ultimately, selecting a PTFE butterfly valve is an investment in your system's safety, purity, and long-term operational efficiency.

Summary Table:

| Key Benefit | Industrial Impact |

|---|---|

| Unmatched Chemical Resistance | Protects valve from corrosive acids and solvents, ensuring long service life. |

| Superior Non-Stick Surface | Prevents media buildup, reduces actuation torque, and ensures contamination-free flow. |

| High Purity & Contamination Control | Essential for pharmaceutical, food & beverage, and semiconductor manufacturing. |

| Wide Temperature Stability | Performs reliably in extreme heat, cryogenic conditions, and frequent thermal cycling. |

| Enhanced Safety & Reduced Downtime | Prevents hazardous leaks and minimizes maintenance, protecting personnel and productivity. |

Ready to enhance your system's reliability and purity with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the exact valve solution—from prototypes to high-volume orders—that delivers unmatched chemical resistance and contamination control for your critical applications.

Contact our experts today to discuss your specific needs and receive a custom solution quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications