In short, adding 55% bronze and 5% MoS2 to a PTFE base creates a high-performance composite material for demanding mechanical applications. This specific formulation dramatically improves wear resistance, load-bearing capacity, and the ability to dissipate heat compared to standard PTFE, while maintaining a very low coefficient of friction.

The core benefit is transformation. This compound turns the soft, chemically resistant nature of PTFE into a robust engineering material capable of handling significant mechanical stress and heat, making it suitable for high-load and high-speed dynamic systems.

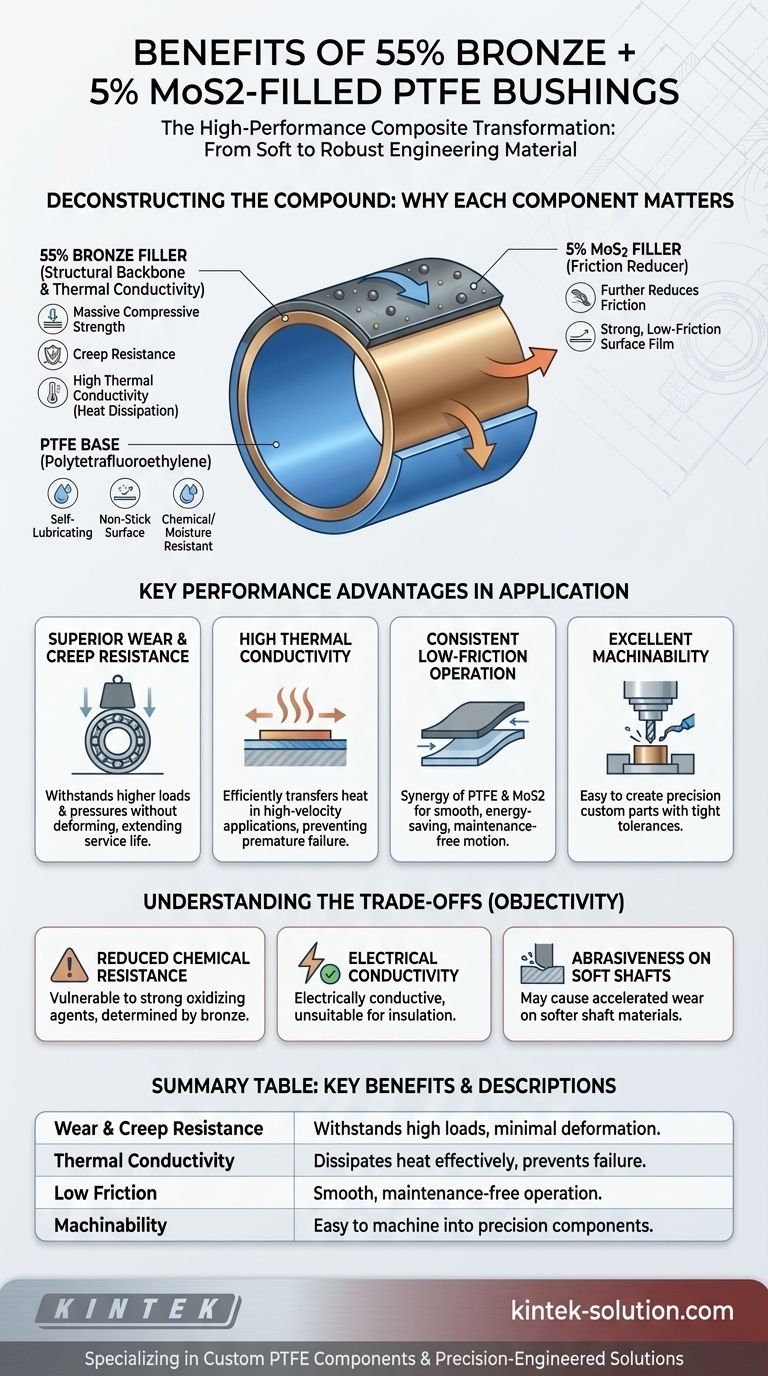

Deconstructing the Compound: Why Each Component Matters

To understand the benefits of this material, you must first understand the role each ingredient plays. The properties are not just a list; they are the direct result of combining three distinct materials.

The PTFE Base: The Foundation of Low Friction

Polytetrafluoroethylene (PTFE) is the polymer matrix that holds the compound together. On its own, it provides the foundational benefits of being self-lubricating, possessing a non-stick surface, and having excellent chemical and moisture resistance.

The Bronze Filler (55%): The Structural Backbone

Adding a high percentage of bronze powder fundamentally changes the mechanical properties of the soft PTFE. Bronze provides a massive increase in compressive strength and creep resistance, which is the material's ability to resist deforming under a constant load.

Crucially, bronze provides high thermal conductivity. It pulls heat away from the sliding surface, preventing thermal expansion and premature failure in high-speed applications.

The MoS2 Filler (5%): The Friction Reducer

Molybdenum disulfide (MoS2) is a well-known solid lubricant. While PTFE is already slippery, adding MoS2 further reduces the coefficient of friction, especially under load. It helps create a strong, low-friction surface film for smooth, maintenance-free operation.

Key Performance Advantages in Application

The combination of these materials results in a bushing with a specific set of advantages tailored for challenging environments.

Superior Wear and Creep Resistance

The bronze filler acts as a structural reinforcement. This allows the bushing to withstand much higher loads and pressures without deforming or wearing out quickly, extending the service life of the application.

High Thermal Conductivity

This is one of the most significant advantages over unfilled or glass-filled PTFE. In high-velocity sliding applications, friction generates heat. The bronze filler efficiently transfers this heat away, maintaining dimensional stability and preventing failure.

Consistent Low-Friction Operation

The synergy between the self-lubricating PTFE and the MoS2 filler ensures the bushing operates with minimal friction. This reduces energy consumption, lowers operating temperatures, and allows for quiet, smooth motion.

Excellent Machinability

Despite its high metal content, this compound remains easy to machine. This allows for the creation of precision components and custom sizes with tight tolerances, which is a significant practical benefit for manufacturing.

Understanding the Trade-offs

No material is perfect for every situation. Objectivity requires acknowledging this compound's limitations.

Reduced Chemical Resistance

While still very good, the chemical resistance is determined by the bronze filler, not just the PTFE. Strong oxidizing agents or other chemicals that attack copper alloys will degrade this material in ways that pure PTFE would not.

Electrical Conductivity

Pure PTFE is an excellent electrical insulator. The high percentage of bronze filler makes this compound electrically conductive. This makes it completely unsuitable for applications requiring electrical insulation.

Abrasiveness on Soft Shafts

The hardness imparted by the bronze can make this material more abrasive than unfilled PTFE. When paired with softer shaft materials, such as aluminum, it may cause accelerated wear on the shaft itself.

Making the Right Choice for Your Goal

Select a material based on the primary demand of your application.

- If your primary focus is high-load or high-speed performance: This 55% Bronze + 5% MoS2 compound is an excellent choice due to its superior wear resistance and thermal conductivity.

- If your primary focus is electrical insulation or universal chemical resistance: You should use unfilled PTFE or a version with a non-metallic filler like glass or Ekonol.

- If your primary focus is reducing wear on a soft shaft material: Consider a less abrasive filled PTFE, such as one filled with glass fiber, which is harder than PTFE but less abrasive than bronze.

Ultimately, choosing this bronze-filled PTFE is a decision for when mechanical strength and heat management are your most critical design problems.

Summary Table:

| Key Benefit | Description |

|---|---|

| Wear & Creep Resistance | Withstands high loads and pressures with minimal deformation, extending service life. |

| Thermal Conductivity | Bronze filler dissipates heat effectively, preventing failure in high-speed applications. |

| Low Friction | PTFE and MoS2 synergy ensures smooth, low-friction, and maintenance-free operation. |

| Machinability | Easy to machine into precision components with tight tolerances. |

Need a high-performance bushing for demanding conditions?

KINTEK specializes in manufacturing custom PTFE components, including 55% Bronze + 5% MoS2-filled bushings, seals, and liners. We deliver precision-engineered solutions for the semiconductor, medical, laboratory, and industrial sectors, from prototypes to high-volume orders.

Contact our experts today to discuss how our materials can solve your high-load and high-speed design challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech