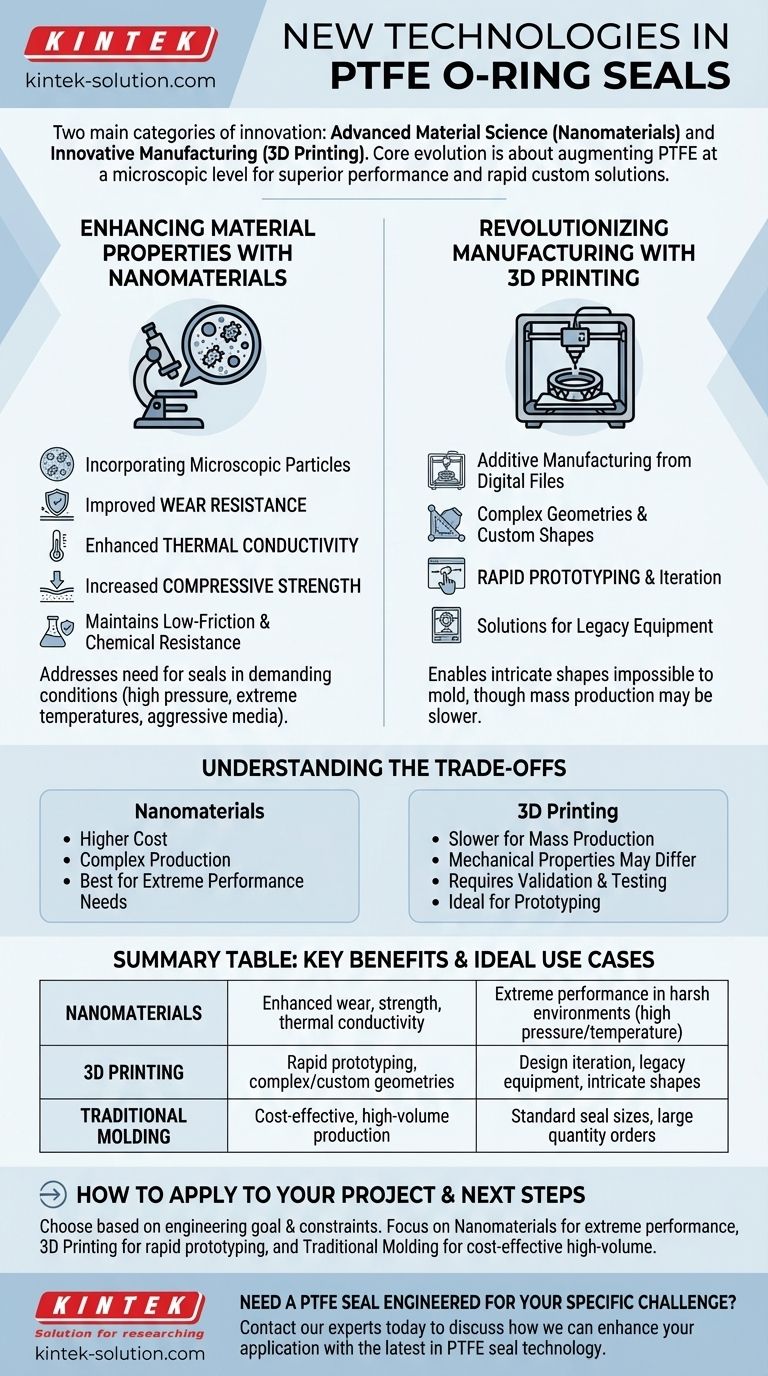

In short, the most significant new technologies being applied to Polytetrafluoroethylene (PTFE) O-ring seals fall into two main categories: advanced material science through the use of nanomaterials and innovative manufacturing processes like 3D printing. These advancements focus on enhancing the inherent properties of PTFE and revolutionizing how custom or complex seals are produced.

The core evolution in PTFE seal technology is not about replacing the material, but about augmenting it at a microscopic level and rethinking how it is formed. This allows for specialized seals with superior performance and enables rapid development of custom solutions that were previously impractical.

The Two Pillars of PTFE Seal Innovation

Innovations in PTFE seals are advancing on two parallel fronts. The first involves fundamentally improving the material itself, while the second focuses on transforming the methods used to create the final product.

Enhancing Material Properties with Nanomaterials

The traditional method for improving PTFE involves adding fillers like glass, carbon, or graphite. The use of nanomaterials is the next evolution of this principle.

By incorporating microscopic particles into the PTFE matrix, manufacturers can precisely engineer the final material's characteristics. This allows for significant improvements in wear resistance, thermal conductivity, and compressive strength without sacrificing PTFE's low-friction and chemical-resistant nature.

This technology directly addresses the need for seals that can withstand more demanding operating conditions, such as higher pressures, extreme temperatures, or aggressive media.

Revolutionizing Manufacturing with 3D Printing

Historically, PTFE seals are made using compression molding—a process ideal for high-volume production of standard sizes. While effective, it can be slow and costly for custom designs.

3D printing, or additive manufacturing, changes this dynamic completely. It allows for the creation of complex geometries and one-off prototypes directly from a digital file.

This is a critical advantage for engineers needing to rapidly iterate on a design, create seals for legacy equipment, or develop components with intricate shapes that are impossible to mold.

Understanding the Trade-offs

While these new technologies are powerful, they are not a universal replacement for traditional methods. It is critical to understand their current limitations.

The Cost and Complexity of Nanomaterials

Nano-enhanced PTFE compounds are specialized materials. Their production is more complex and, as a result, they are typically more expensive than standard filled-PTFE grades.

Their application is best justified in situations where conventional seals fail or where the performance benefits directly translate into longer service life and reduced downtime, offsetting the initial cost.

The Limitations of Current 3D Printing

While revolutionary for prototyping, 3D printing PTFE seals for mass production is often slower and less cost-effective than compression molding.

Furthermore, the mechanical properties and surface finish of a 3D-printed part may differ from a molded one. Thorough validation and testing are essential to ensure a printed seal meets the performance requirements of a demanding application.

How to Apply This to Your Project

Choosing the right technology depends entirely on your specific engineering goal and operational constraints.

- If your primary focus is extreme performance and durability: Investigate nano-enhanced PTFE materials for applications where standard seals fall short.

- If your primary focus is rapid prototyping or complex custom shapes: Utilize 3D printing to accelerate your design cycle and create solutions not possible with molding.

- If your primary focus is cost-effective production of standard seals: Traditional compression molding remains the most reliable and economical choice for high-volume needs.

Ultimately, understanding these technological advancements empowers you to select the precise sealing solution for the engineering challenge at hand.

Summary Table:

| Technology | Key Benefit | Ideal Use Case |

|---|---|---|

| Nanomaterials | Enhanced wear resistance, strength, and thermal conductivity | Extreme performance in harsh environments (high pressure/temperature) |

| 3D Printing | Rapid prototyping and complex, custom geometries | Design iteration, legacy equipment, and intricate shapes |

| Traditional Molding | Cost-effective, high-volume production | Standard seal sizes and large quantity orders |

Need a PTFE Seal Engineered for Your Specific Challenge?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Whether your project demands the enhanced properties of nano-filled materials, the flexibility of 3D printed prototypes, or the reliability of high-volume molded parts, our expertise in custom fabrication from prototypes to production runs ensures you get a precision solution that fits your exact needs.

Contact our experts today to discuss how we can enhance your application with the latest in PTFE seal technology.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the key properties of PTFE that make it suitable for seals? Unlock Reliability in Extreme Conditions

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat