The primary lubrication benefit of PTFE bushes is that they are inherently self-lubricating. Polytetrafluoroethylene (PTFE) is a polymer with an extremely low coefficient of friction, which allows moving parts to operate smoothly without the need for external oils or greases. This reduces maintenance requirements and simplifies the design of mechanical systems.

PTFE bushes solve the problem of friction by eliminating the need for traditional, messy lubricants. This makes them ideal for applications where maintenance is difficult, cleanliness is critical, or operating conditions are too harsh for oils and greases.

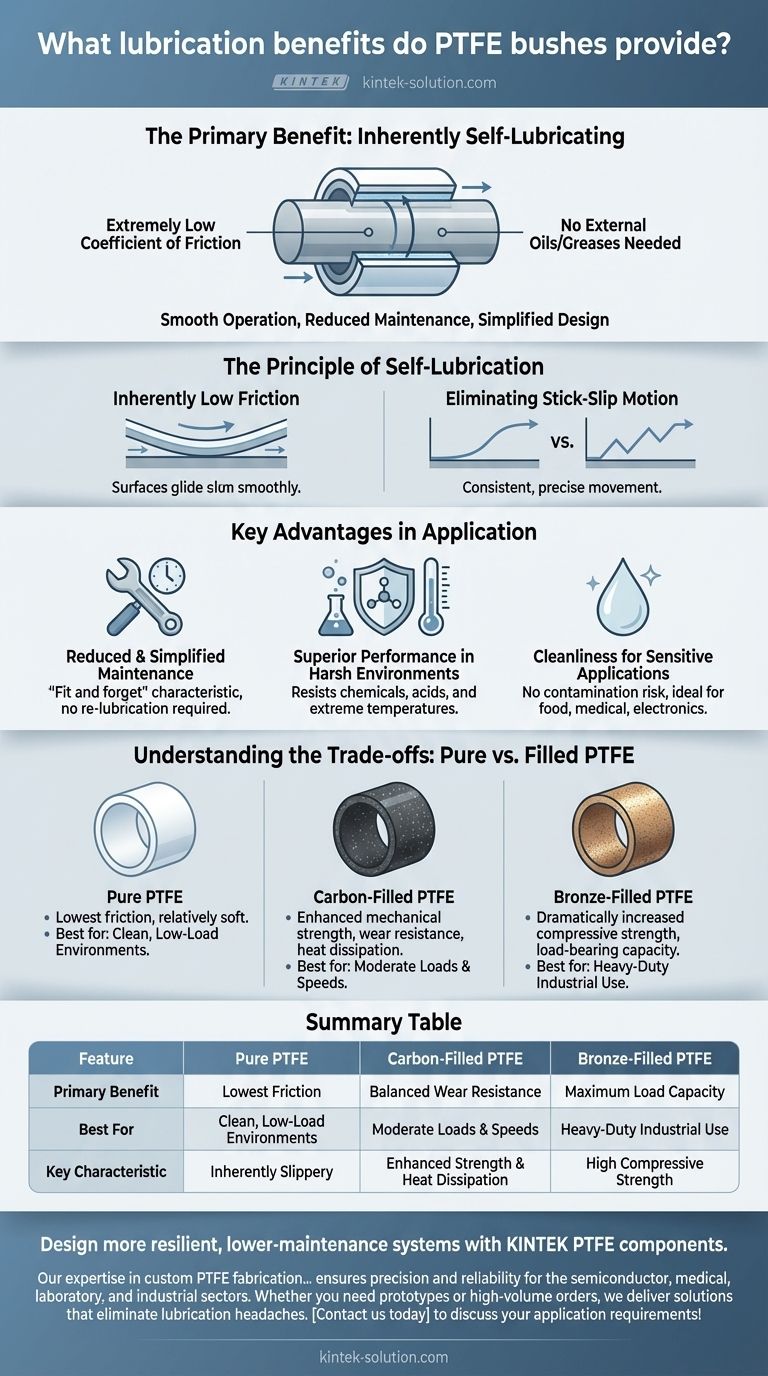

The Principle of Self-Lubrication

An Inherently Low Coefficient of Friction

PTFE is one of the most slippery solid materials known, giving it a naturally low coefficient of friction. This property is intrinsic to the material itself.

When a shaft rotates or slides within a PTFE bush, the motion is inherently smooth. It doesn't rely on a film of oil or grease to separate the two surfaces.

Eliminating Stick-Slip Motion

This consistent, low-friction surface helps eliminate "stick-slip" phenomena, where parts can jerk at the start of motion. This ensures smoother, more precise movement, which is critical in high-performance or precision machinery.

Key Advantages in Application

Reduced and Simplified Maintenance

The most significant advantage is the reduction in maintenance. There is no need for a schedule to re-apply grease or top up oil reservoirs.

This "fit and forget" characteristic is invaluable in machinery where access is limited or downtime is extremely costly.

Superior Performance in Harsh Environments

PTFE is highly resistant to chemicals, acids, and corrosive substances. In environments where lubricants would degrade or wash away, PTFE bushes continue to perform reliably.

They also operate effectively across a wide range of temperatures, from cryogenic lows to highs where conventional lubricants would burn off or solidify.

Cleanliness for Sensitive Applications

Because they require no external lubrication, PTFE bushes are perfect for industries like food processing, medical devices, and electronics manufacturing.

There is no risk of lubricant contamination, which is a critical requirement for compliance and product safety in these fields.

Understanding the Trade-offs: Pure vs. Filled PTFE

While pure PTFE offers the lowest friction, it is a relatively soft material with limited mechanical strength and wear resistance under high loads or speeds. To overcome this, fillers are added to create composite materials with enhanced properties.

Carbon-Filled PTFE

Adding carbon improves the bush's mechanical strength, dimensional stability, and wear resistance.

Carbon also enhances thermal conductivity, helping to dissipate heat that can build up from friction in higher-speed applications. This makes it suitable for moderate to high loads.

Bronze-Filled PTFE

Bronze is added to dramatically increase the bush's compressive strength and load-bearing capacity.

Bronze-filled bushes are exceptionally resistant to wear and are ideal for heavy-duty industrial and automotive applications where parts are subjected to significant force.

Making the Right Choice for Your Application

Choosing the correct PTFE bush depends entirely on the mechanical demands of your system.

- If your primary focus is the lowest possible friction in a clean, low-load environment: A pure or FDA-compliant PTFE bush is the ideal choice.

- If your primary focus is wear resistance and performance under moderate loads: A carbon-filled PTFE bush offers a balanced profile of strength and low friction.

- If your primary focus is maximum strength and load capacity for heavy-duty use: A bronze-filled PTFE bush provides the durability required for the most demanding applications.

Ultimately, leveraging PTFE's self-lubricating properties allows you to design more resilient, lower-maintenance, and cleaner mechanical systems.

Summary Table:

| Feature | Pure PTFE | Carbon-Filled PTFE | Bronze-Filled PTFE |

|---|---|---|---|

| Primary Benefit | Lowest Friction | Balanced Wear Resistance | Maximum Load Capacity |

| Best For | Clean, Low-Load Environments | Moderate Loads & Speeds | Heavy-Duty Industrial Use |

| Key Characteristic | Inherently Slippery | Enhanced Strength & Heat Dissipation | High Compressive Strength |

Design more resilient, lower-maintenance systems with KINTEK PTFE components.

Our expertise in custom PTFE fabrication—from seals and liners to labware—ensures precision and reliability for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, we deliver solutions that eliminate lubrication headaches.

Contact us today to discuss your application requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is Teflon preferred for sealing applications? Unmatched Chemical & Thermal Resistance

- What makes PTFE superior in terms of chemical resistance compared to rubber seals? The Key to Unmatched Reliability

- What are the advantages of spring-energized PTFE seals? Achieve Superior Sealing in Extreme Conditions

- What are the different forms of PTFE used for manufacturing gaskets and seals? Choose the Right Material for Your Application

- What advantages do Teflon washers have over nylon and plastic washers? Achieve Superior Performance in Harsh Environments

- What challenges are associated with fabricating PTFE substrates? Mastering Precision with High-Frequency Materials

- What are the primary applications of Teflon parts in the aerospace industry? Essential for Seals, Bearings & Insulation

- What are some common automotive applications of PTFE seals? Solve High-Temp, High-Speed Sealing Challenges