At its core, Teflon is preferred for industrial sealing because it offers an unparalleled combination of chemical inertness, thermal stability, and low-friction properties. This unique blend allows it to create a reliable and long-lasting seal in harsh operational environments where most other materials would quickly degrade and fail.

The true value of Teflon in sealing applications is its versatility. It reliably performs in environments with extreme chemicals, wide temperature ranges, and high pressure, making it a default choice for the most demanding industrial challenges.

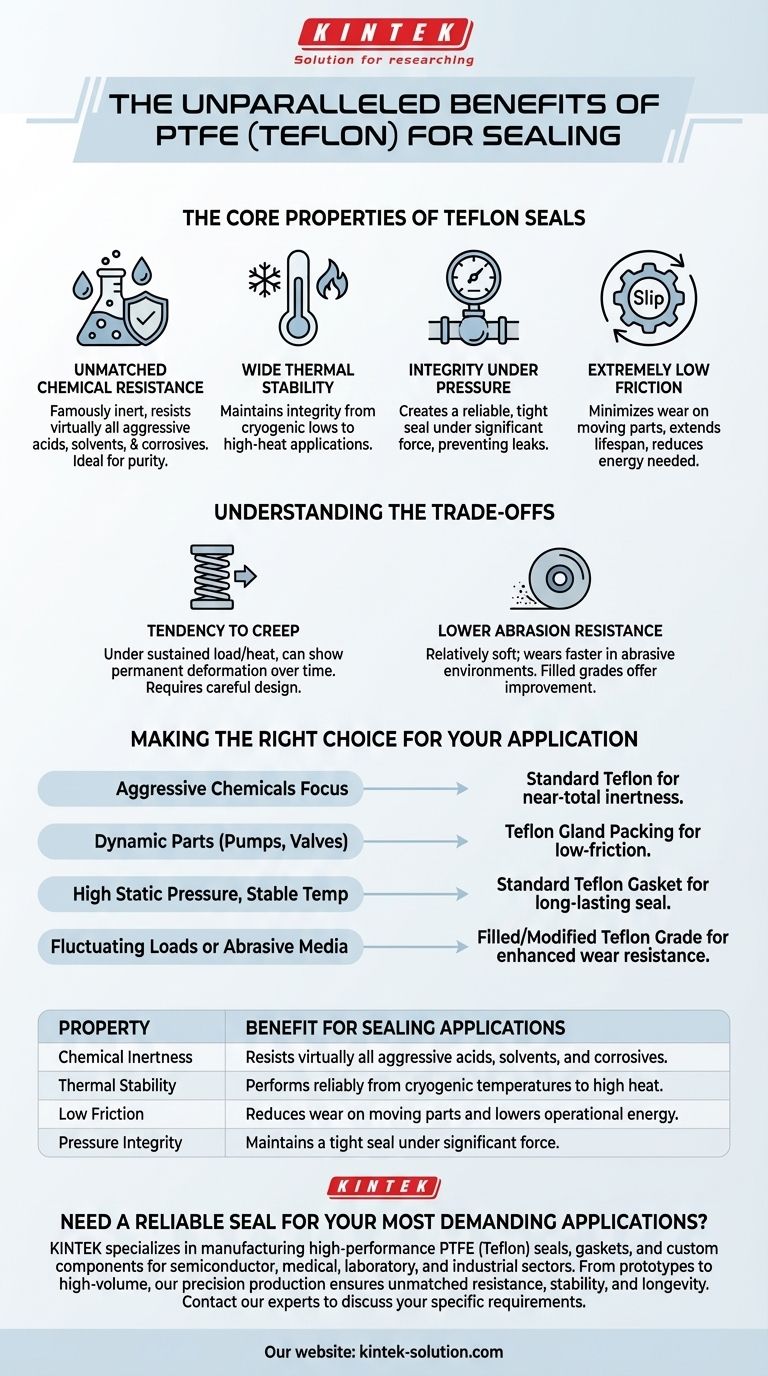

The Core Properties of Teflon Seals

To understand why Teflon (PTFE) is so dominant, we must examine its fundamental material characteristics. Each property directly solves a critical challenge in industrial sealing.

Unmatched Chemical Resistance

Teflon is famously inert, meaning it is almost completely resistant to chemical attack. It will not swell, dissolve, or degrade when exposed to the vast majority of aggressive acids, solvents, and corrosive agents used in industrial processes.

This makes it an essential material for gaskets, O-rings, and valve seats in chemical processing, pharmaceuticals, and manufacturing where product purity and safety are paramount.

Wide Thermal Stability

Sealing materials must maintain their integrity across a wide spectrum of operating temperatures. Teflon excels here, remaining stable and effective in conditions ranging from cryogenic lows to high-heat applications.

This thermal resilience ensures a consistent, reliable seal whether the system is handling liquefied gases or high-temperature steam, preventing leaks caused by material failure.

Integrity Under Pressure

A primary function of any seal is to prevent leaks under pressure. Teflon maintains its structural integrity and creates a tight seal even when subjected to significant force.

This quality is crucial for high-pressure hydraulic systems, pumps, and valves, where seal failure could lead to equipment damage, downtime, and safety hazards.

Extremely Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, making it incredibly "slippery." For dynamic seals like gland packing in pumps, this property is critical.

A low-friction surface minimizes wear and tear on moving parts like rotating shafts, reduces the energy needed to operate the equipment, and significantly extends the lifespan of both the seal and the machinery.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations, which must be considered during material selection and system design.

Tendency to Creep

Under a sustained mechanical load, especially at elevated temperatures, Teflon can exhibit "creep" or "cold flow." This is a slow, permanent deformation of the material.

Over time, this can cause a loss of sealing pressure, potentially leading to leaks if the joint is not designed with this property in mind or periodically re-torqued.

Lower Abrasion Resistance

Compared to harder plastics or metals, Teflon is a relatively soft material. In applications involving abrasive slurries or particulate matter, it can wear down more quickly.

For these environments, filled grades of Teflon (mixed with materials like glass fiber or carbon) are often used to enhance hardness and wear resistance.

Making the Right Choice for Your Application

Selecting the correct sealing material depends entirely on the specific demands of your system.

- If your primary focus is sealing aggressive chemicals: Teflon's near-total inertness makes it the safest and most reliable choice.

- If you are sealing dynamic parts like pump shafts or valve stems: Teflon gland packing is ideal due to its low-friction surface, which prevents wear.

- If your application involves high static pressure at stable temperatures: A standard Teflon gasket provides an excellent, long-lasting seal.

- If your system involves fluctuating loads or abrasive media: Consider a filled or modified grade of Teflon to improve its resistance to creep and wear.

Ultimately, choosing Teflon is a decision to prioritize reliability and longevity in the most challenging industrial environments.

Summary Table:

| Property | Benefit for Sealing Applications |

|---|---|

| Chemical Inertness | Resists virtually all aggressive acids, solvents, and corrosives. |

| Thermal Stability | Performs reliably from cryogenic temperatures to high heat. |

| Low Friction | Reduces wear on moving parts and lowers operational energy. |

| Pressure Integrity | Maintains a tight seal under significant force. |

Need a reliable seal for your most demanding applications?

KINTEK specializes in manufacturing high-performance PTFE (Teflon) seals, gaskets, and custom components. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production and custom fabrication—from prototypes to high-volume orders—ensure you get a seal that delivers unmatched chemical resistance, thermal stability, and longevity.

Contact our experts today to discuss your specific requirements and get a solution tailored to your operational challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions