In the aerospace industry, Teflon (PTFE) parts are primarily used for critical seals, gaskets, low-friction bearings, and high-performance electrical and thermal insulation. Its unique combination of chemical inertness, resistance to extreme temperatures, and an exceptionally low coefficient of friction makes it indispensable for components where reliability and performance are non-negotiable.

The core reason Teflon is so prevalent in aerospace is not just a single property, but its rare ability to solve three critical engineering problems simultaneously: managing aggressive fluids, reducing friction in moving parts, and withstanding extreme temperatures.

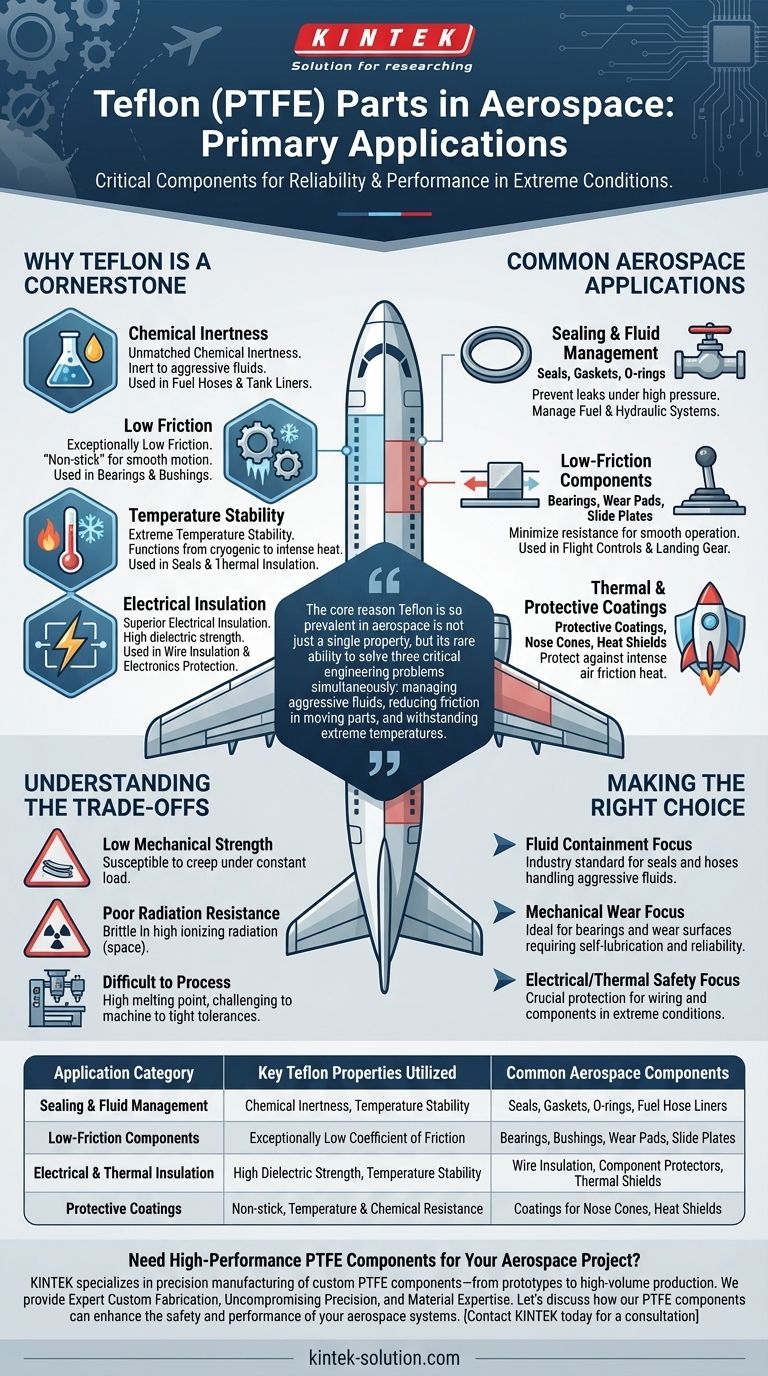

Why Teflon is a Cornerstone of Aerospace Engineering

The demanding environment of an aircraft—from corrosive fuels and hydraulic fluids to massive temperature swings and constant vibration—requires materials that can perform without failure. Teflon, a fluoropolymer technically known as Polytetrafluoroethylene (PTFE), possesses a set of properties that makes it uniquely suited for these challenges.

Unmatched Chemical Inertness

Teflon is virtually inert and does not react with the vast majority of chemicals. This is critical in aerospace for containing aggressive substances.

Applications like fuel hoses and tank liners rely on this property to safely manage jet fuel and hydraulic fluids without degrading the material or contaminating the system.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" quality is essential for mechanical systems.

It allows bearings and bushings in flight control surfaces or landing gear to move smoothly and reliably without the need for external lubrication, reducing maintenance and points of failure.

Extreme Temperature Stability

Aerospace components are exposed to a wide thermal range, from cryogenic temperatures at high altitudes to intense heat near engines and during atmospheric re-entry.

Teflon maintains its structural integrity and performance properties across this vast spectrum, making it ideal for seals, gaskets, and thermal insulation that must function in extreme heat or cold.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with a high dielectric strength, meaning it can withstand high voltages without breaking down.

This makes it a first-choice material for insulating high-performance wiring and protecting sensitive electronic components from short-circuiting and electromagnetic interference.

Common Aerospace Applications in Detail

The core properties of Teflon translate directly into specific, high-stakes applications throughout an aircraft.

Sealing and Fluid Management

Components like seals, gaskets, and O-rings made from Teflon are used throughout an aircraft's fuel and hydraulic systems. Their job is to prevent catastrophic leaks under high pressure and fluctuating temperatures.

Low-Friction Mechanical Components

In systems that require smooth, repeatable motion, such as actuators for flight controls, Teflon bearings, wear pads, and slide plates are used to minimize resistance and wear, ensuring precise and reliable operation.

Thermal and Protective Coatings

Beyond solid parts, Teflon is used for protective coatings. On a larger scale, it has been used in components like nose cones and heat shields to protect against the intense heat generated by air friction at high speeds.

Understanding the Trade-offs

While its benefits are significant, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations.

Relatively Low Mechanical Strength

Compared to metals or other engineering plastics, PTFE is soft and has poor tensile strength. It can be susceptible to creep, where the material slowly deforms under a constant load.

Poor Radiation Resistance

Standard PTFE does not hold up well to high levels of ionizing radiation found in space, which can cause the material to become brittle. This limits its use in certain satellite and deep-space applications without specialized formulation.

Difficult to Process

Teflon's high melting point and unique properties can make it challenging to process and machine to extremely tight tolerances, which can increase manufacturing costs.

Making the Right Choice for Your Goal

Selecting Teflon is about matching its unique strengths to a specific engineering problem.

- If your primary focus is fluid containment: Teflon is the industry standard for seals and hoses that must handle aggressive aerospace fuels and hydraulic fluids without degrading.

- If your primary focus is reducing mechanical wear: Its self-lubricating, low-friction nature is ideal for bearings and wear surfaces in critical moving systems where reliability is paramount.

- If your primary focus is electrical or thermal safety: Teflon’s stability and insulating properties provide a crucial layer of protection for wiring and components exposed to extreme conditions.

Ultimately, Teflon's unique combination of properties makes it an indispensable material for ensuring safety and reliability in the demanding world of aerospace.

Summary Table:

| Application Category | Key Teflon Properties Utilized | Common Aerospace Components |

|---|---|---|

| Sealing & Fluid Management | Chemical Inertness, Temperature Stability | Seals, Gaskets, O-rings, Fuel Hose Liners |

| Low-Friction Components | Exceptionally Low Coefficient of Friction | Bearings, Bushings, Wear Pads, Slide Plates |

| Electrical & Thermal Insulation | High Dielectric Strength, Temperature Stability | Wire Insulation, Component Protectors, Thermal Shields |

| Protective Coatings | Non-stick, Temperature & Chemical Resistance | Coatings for Nose Cones, Heat Shields |

Need High-Performance PTFE Components for Your Aerospace Project?

KINTEK specializes in the precision manufacturing of custom PTFE components—from prototypes to high-volume production. We understand the critical demands of the aerospace industry for reliability in extreme conditions.

We provide:

- Expert Custom Fabrication: We tailor seals, liners, bearings, and complex labware to your exact specifications.

- Uncompromising Precision: Our manufacturing processes ensure tight tolerances and consistent quality for mission-critical parts.

- Material Expertise: Deep knowledge of PTFE properties to recommend the optimal solution for your application involving aggressive fluids, extreme temperatures, or electrical insulation.

Let's discuss how our PTFE components can enhance the safety and performance of your aerospace systems.

Contact KINTERO today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs